What is a programmable logic controller

Controller (from English Control) — control. The controller in automated systems is a technical tool that performs the functions of controlling physical processes in accordance with the defined algorithm, using information received from sensors and displayed on end devices. Any device that can operate automatically includes a control controller — a module that defines the logic of the device's operation.

Programmable Logic Controllers (PLC) — technical means used to automate technological processes. It is an electronic specialized device working in real time.

A PLC can be digitally programmed and thus very easily adapted to the requirements of a particular process. With the increasing demands on modern machines and production processes, PLC automation solutions have become an integral part of daily industrial production.

The main mode of operation of a PLC is its long-term autonomous use, often under adverse environmental conditions, without major maintenance and without human intervention.PLCs are typically used to control sequential processes, using inputs and outputs to determine the state of an object and issue control actions.

Programmable logic controllers are ideal for individual control of various applications, machines, systems and processes or digital power management.

A programmable logic controller is a microprocessor device designed to collect, convert, process, store information and generate control commands, having a finite number of inputs and outputs, sensors, switches, actuators connected to them to the control object, and designed to operate in real-time modes.

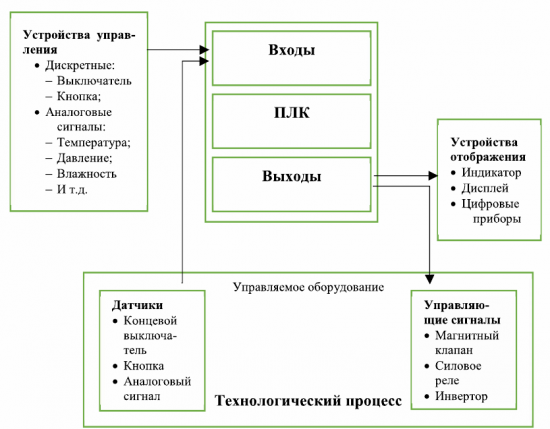

A typical PLC consists of the following parts:

- For example, buttons, light barriers or temperature sensors are connected to the control unit via the inputs. Thanks to these components, the PLC system can monitor the current state of the machine.

- The outputs are connected to a device such as electric motors, hydraulic valves that the PLC uses to control a particular machine.

- User program — PLC software, provides switching of outputs depending on the activation of inputs.

- The communication interface is used to connect the PLC to other systems.

- A PLC also includes its own power supply, CPU and internal bus.

Currently used relay-contact control systems are characterized by low reliability, presence of open contacts, etc. The use of programmable logic controllers (PLCs) for the automation of local control systems is the most effective.

Over time, PLCs continue to evolve and adapt to specific needs in the industrial environment.PLC functions have a number of advantages: due to their flexibility, they can be used in a wide variety of industries. Settings can be changed at any time without interfering with the operation of the equipment itself.

Only individually programmable devices for control, monitoring and regulation of the performance of production machines can satisfy the high requirements of modern industry.

A PLC can usually be installed directly on the production machine. This saves the necessary space. Besides being able to remotely control a PLC, one of its biggest advantages is its communication capability.

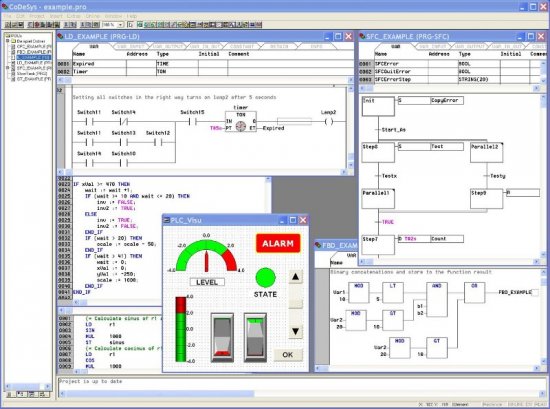

PLCs are programmed in accordance with the IEC-61131-3 standard. PLCs are programmed with the help of specialized complexes, one of the most popular is CoDeSys. It includes the following languages: graphic (bar diagram, function block diagram, sequential function diagram, continuous function diagram), text (list of instructions, structured text).

The world's first programmable logic controller appeared in the middle of the 20th century. The Modicon 084 was a cabinet with a set of interconnected relays and contacts, its memory was only 4 kilobytes. The term PLC was coined by Allen-Bradley in 1971. Together with Richard Morley, he is the «father of PLC».

The first of these systems is attributed to two technicians, Richard E. Morley and Odo J. Struger. While Morley introduced his Modicon 084 system as a "semiconductor semiconductor computer" in 1969, Odo J. Struger helped develop PLCs for Wisconsin-based Allen-Bradley. Both engineers are considered the creators of the first programmable logic controller (PLC).Over time, the demands on production environments around the world have grown. Thus the PLC evolved and was put into service in many versions.

— Electrical engineer Yakov Kuznetsov

The structure of the programmable logic controller:

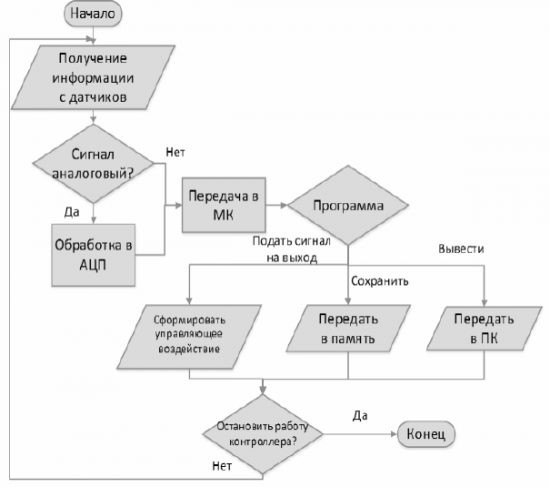

PLC work algorithm:

The main mode of operation of a PLC is its long-term autonomous use, often under adverse environmental conditions, without major maintenance and practically without human intervention.

PLCs have a number of characteristics that distinguish them from other electronic devices used in mechanical engineering:

-

Unlike a microcontroller (single-chip computer)—a microcircuit designed to control electronic devices—PLCs are typically used in automated industrial production processes in the context of a manufacturing plant;

-

unlike computers, PLCs are focused on working with machine units through sophisticated input of sensory signals and output of signals to actuators, focused on decision-making and operator control;

-

Unlike embedded systems, PLCs are manufactured as independent products, separate from the equipment they control.

-

the presence of an expanded number of logical operations and the ability to set timers and counters.

-

All PLC programming languages have easy access to bit manipulation in machine words, unlike most high-level programming languages on modern computers.

There are PLCs with different levels of complexity, depending on the complexity of the automation tasks to be solved.

The basic operations of a PLC correspond to the combined control of logic circuits of specific units — mechanical, electrical, hydraulic, pneumatic and electronic.

In the control process, controllers generate output signals (on — off) to control actuators (electric motors, valves, solenoids, and valves) based on the results of processing signals received from sensors or higher-level devices.

Modern programmable controllers also perform other operations, such as combining the functions of a counter and an interval timer, and handling signal delays.

Mid-level and high-level programmable logic controllers typically have built-in motion control hardware and software, particularly high-speed counter modules, positioning modules, etc., which enable relatively easy implementation of motion control functions and provide high precision positioning.

Structurally, PLCs are adapted to operate in typical industrial conditions, taking into account polluted atmospheres, signal levels, thermal and moisture resistance, unreliability of power supplies, as well as mechanical shocks and vibrations. For this purpose, the hardware part is enclosed in a robust housing that minimizes the negative impact of a number of production factors.

The main difference between PLC and relay control circuits is the algorithms that are implemented using programs. A single controller can implement circuitry equivalent to thousands of hard logic elements. Moreover, the reliability of the circuit does not depend on its complexity.

Programmable logic controllers traditionally operate at the bottom of automated plant control systems (ACS)—systems directly related to manufacturing technologies.

PLCs are usually the first step in building control systems. This is because the need to automate a machine or plant is always the most obvious. It gives a quick economic effect, improves the quality of production, avoids physically demanding and routine work. PLCs by definition are built for this job.

The main advantage of PLC is that a small mechanism can replace a huge number of electromechanical relays, as well as fast scan time, compact I / O systems, standardized programming tools and special interfaces that allow the connection of non-standard automation devices directly to the controller or combining different equipment into a single control system.

How to choose the right PLC

Choosing a programmable controller is an important and difficult task when creating systems for automatic control of technological parameters in any industrial enterprise.

When choosing it, it is necessary to take into account and evaluate a large number of factors. By combining the technological requirements for a specific object for automatic control with a comparative analysis of modern programmable logic controllers, you can make the right decision.

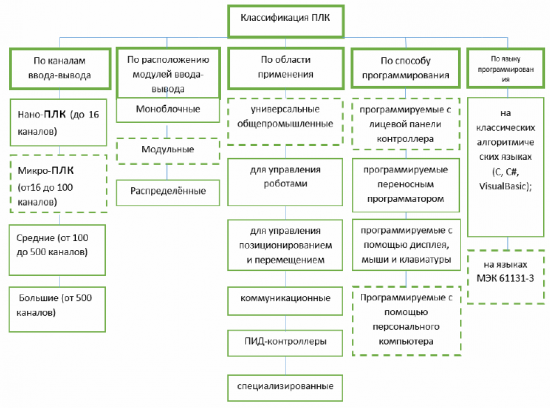

PLC classification:

When buying a PLC, the first step is to carefully consider which type is right for the purpose.

Classic PLCs are modules that can usually be programmed using a computer. After that, the computer is no longer needed to operate the PLC itself.In principle, a distinction must be made between modular, compact and slotted PLCs.

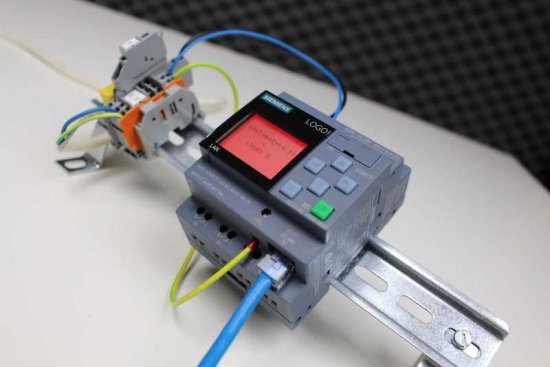

Compact PLCs are generally cheaper and take up less space. After that, it is mainly used for small automation processes.

In addition to applications based on the PC platform, there are also compact PLCs that can be programmed from a control panel without a PC.

Modular PLCs offer the ability to flexibly assemble the control unit from individual modules so that more complex automated tasks can be programmed.

There are modules that can be implemented in the system as plug-in cards in a free slot on the motherboard.

It is also necessary to distinguish between PLCs in the way they do their work. In addition to models that control inputs in a predetermined cycle and PLCs that process outputs at various stages, event-driven PLC models are also available.

Before buying a PLC, you should pay special attention to the number of inputs and outputs. In addition, it is necessary to consider other parameters that were not taken into account during the initial planning. Also consider whether you need a PLC with an integrated display and touch panel. In some cases, reading the values and managing the system through the existing IT infrastructure may be sufficient.

What is HMI

HMI (Human Machine Interface) — a human-machine communication interface. These intuitive and user-friendly interfaces are used to allow users to operate and operate machines without in-depth knowledge of PLC programming. One type of HMI devices are SCADA systems: Data acquisition and operational control systems (SCADA systems)