Electric drive of pipe fittings

Very often, an electric drive is used to control pipeline valves. The electric drive is powered by electricity, which is the most available form of energy today. However, it is not only because of the power supply that the electric drive has gained such popularity.

First, electricity here is consumed only during operation (when opening or closing is required), while direct control can be carried out directly on site or remotely.

Second, automatic control allows minimizing the pause between command and execution (the device is an executive device).

And thirdly, the larger the area and the number of valves served, the greater the distance from which the control is carried out, the higher the overall efficiency when using electric drives.

Today, electric drives successfully and efficiently serve the automation and simple mechanization of pipeline valves. They are widely used in many pipelines and play a crucial role in various industrial processes.

Electric actuators are often installed for the purpose of automated remote control of valves, for unlocking and locking, for continuous adjustment, diagnosis and monitoring of the current position of the valve.

The kinetic energy of the rotating part of the valve can be directed, for example, to open a butterfly valve or ball valve inside the pipe. By the way, the installation and maintenance of the electric drive does not require special personnel training.

Different electric drives differ in torques — from 5 to 10,000 Nm, their design can be conventional or explosion-proof.

The characteristics of electric drives are reflected in their marking, which consists of letters and numbers that reflect: the type of connection with the valve (in letters), the magnitude of the torque (in numbers in Nm) and the speed of the drive shaft of the electric drive ( in rpm), transmitting the rotation to the nut fittings or the spindle, and other important parameters.

Most often, drives are made on the basis of AC motors. Also, the design may contain a power limiter, according to the principle of operation, which valve drives are divided into:

-

friction cam,

-

frictional,

-

electronic,

-

electromechanical,

-

electromagnetic.

Depending on the design of the gearbox, the drive is equipped with a gearbox of one of the following types:

-

worm,

-

planetary,

-

cylindrical,

-

swing screw,

-

complex (when several types of gearboxes are used within one device).

Based on how and how much the working element of the drive moves, drives are distinguished:

-

straight ahead

-

many turns

-

partial rotation,

-

lever.

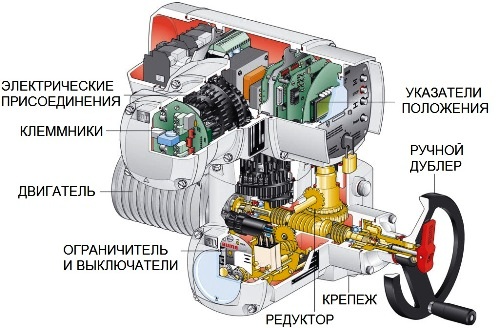

Component parts of the device

First of all, a motor is installed in the drive, as a rule, it is an AC asynchronous motor designed to supply kinetic energy to the device. A power limiting device is then installed to protect the device from overload. The limiting device can be supplemented with a shock absorber, which relieves the valve from the inertial action of the moving parts.

The design also includes travel switches, whose functions are to signal the current position of the working body, to block mechanisms and to turn off the engine power supply.

The rotation from the motor shaft is transmitted to the gearbox, which converts the torque, reduces the speed and increases the power to the level required by the control object. The actuator is attached to the valve by means of a rigid flange connection and a connecting shaft coupling.

A handwheel is required in the event of a power failure and during installation and commissioning - a switch is actuated during use by personnel to disable the engine from starting if the power is suddenly switched on to avoid injury of people.

The position indicator is used to track the current position of the valve, the degree of its opening at any point in time. The position sensor remotely signals the degree of opening of the shut-off valve or the position of the controlled valve (as a feedback sensor).

The power cable and the signal cable are connected to the sensors and to the motor. Some devices are equipped with terminal blocks, which is convenient for infrastructures with advanced process automation systems.

Applications of various electric drives

Electric actuators with a partial turn (quarter turn or one turn) are installed on the valves, where for proper control it is enough to turn the stem 90 degrees. These are ball valves, throttle valves, etc. Here, a large torque is immediately required, since the working body is very tightly pressed, in addition, sealing materials are used.

Multi-turn actuators are suitable for valves, rubber wedge valves, valves and shut-off valves. There is no need for as much starting torque as with part-rotation valves because friction has almost no effect on rotation during actuation.

Alternatively, the multi-turn actuator is fitted together with an auxiliary gearbox on a part-turn valve to increase the power to control large valves that have low power and low-cost electric actuators.

In linear actuators, the rotation of the motor is converted into linear motion of the actuator, therefore, if it is necessary to automate a valve with a smooth stem or a control valve, then a linear actuator is suitable here. For dampers, valves and louvres operated by a lever mechanism - an electric lever actuator is suitable.