The history of the creation and use of magnetic materials

The history of the use of magnetic materials is inextricably linked with the history of discovery and research magnetic phenomena, as well as the history of the development of magnetic materials and the improvement of their properties.

First mentions for magnetic materials date back to ancient times when magnets were used to treat various ailments.

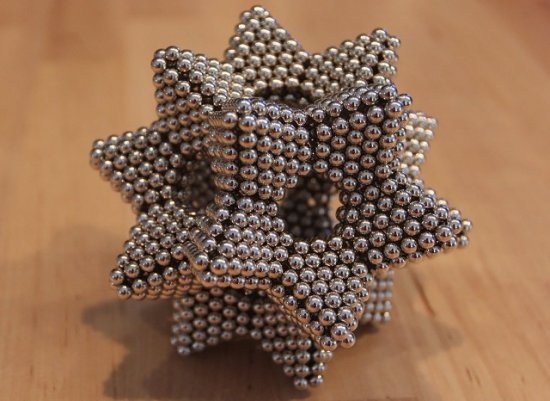

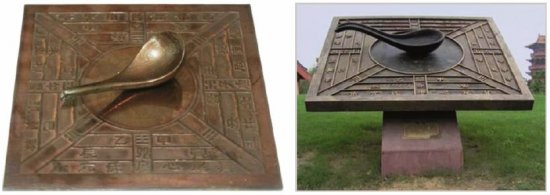

The first device made of a natural material (magnetite) was produced in China during the Han Dynasty (206 BC - AD 220). In the Lunheng text (1st century AD) it is described as follows: "This tool looks like a spoon, and if you put it on a plate, then its handle will point to the south." Despite the fact that such a "device" was used for geomancy, it is considered a prototype of the compass.

Prototype of the compass created in China during the Han Dynasty: a — life-size model; b — monument of the invention

Until about the end of the 18th century.the magnetic properties of natural naturally magnetized magnetite and the iron magnetized with it were used only for the manufacture of compasses, although there are legends of magnets that were installed at the entrance of a house in order to detect iron weapons that could be hidden under an incoming person's clothing.

Despite the fact that for many centuries magnetic materials were used only for the manufacture of compasses, many scientists were engaged in the study of magnetic phenomena (Leonardo da Vinci, J. della Porta, V. Gilbert, G. Galileo, R. Descartes, M. Lomonosov, etc.), who contributed to the development of the science of magnetism and the use of magnetic materials.

The compass needles in use at the time were naturally magnetized or magnetized natural magnetite… It was only in 1743 that D. Bernoulli bent the magnet and gave it the shape of a horseshoe, which greatly increased its strength.

In the XIX century. the research of electromagnetism as well as the development of suitable devices have created prerequisites for the widespread use of magnetic materials.

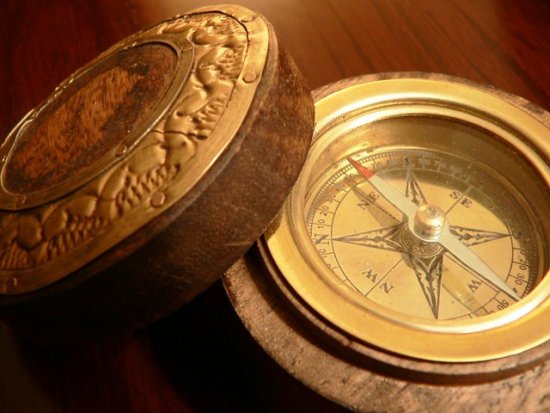

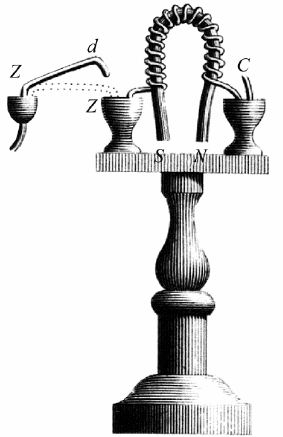

In 1820, HC Oersted discovered the connection between electricity and magnetism. Based on his discovery, W. Sturgeon in 1825 made the first electromagnet, which was an iron rod covered with dielectric varnish, 30 cm long and 1.3 cm in diameter, bent in the form of a horseshoe, on which there were 18 turns of wire wound connected to an electric battery by making contact. The magnetized iron horseshoe can hold a load of 3600 g.

Sturgeon electromagnet (the dotted line shows the position of the movable electrical contact when the electrical circuit is closed)

The works of P. Barlow to reduce the influence on ships' compasses and chronometers of the magnetic field created by the surrounding iron-containing parts belong to the same period. Barlow was the first to put magnetic field shielding devices into practice.

First practical application magnetic circuits related to the history of the invention of the telephone. In 1860, Antonio Meucci demonstrated the ability to transmit sounds over wires using a device called the Teletrophone. A. Meucci's priority was recognized only in 2002, until then A. Bell was considered the creator of the telephone, despite the fact that his 1836 invention application was filed 5 years later than A. Meucci's application.

T.A.Edison was able to amplify the sound of the telephone with the help of transformer, patented simultaneously by P. N. Yablochkov and A. Bell in 1876.

In 1887, P. Janet published a work describing a device for recording sound vibrations. Powder-coated steel paper was inserted into the longitudinal slot of the hollow metal cylinder, which did not completely cut the cylinder. When the current passed through the cylinder, the dust particles had to be oriented in a certain way under the action of magnetic field current.

In 1898, the Danish engineer V. Poulsen practically implemented O. Smith's ideas about sound recording methods. This year can be considered the year of birth of the magnetic recording of information. V. Poulsen used as a magnetic recording medium a steel piano wire with a diameter of 1 mm wound on a non-magnetic roll.

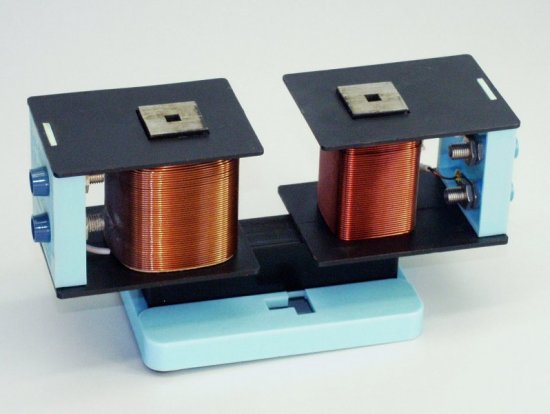

During recording or playback, the reel together with the wire rotates relative to the magnetic head, which moves parallel to its axis. Like magnetic heads used electromagnets, consisting of a rod-shaped core with a coil, one end of which slid over the working layer.

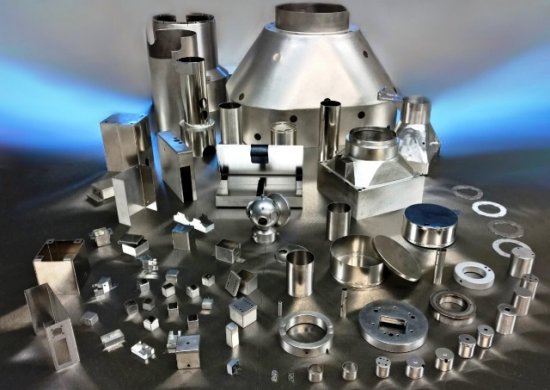

The industrial production of artificial magnetic materials with higher magnetic characteristics became possible only after the development and improvement of metal melting technologies.

In the XIX century. the main magnetic material is steel containing 1.2 ... 1.5% carbon. From the end of the XIX century. began to be replaced by steel alloyed with silicon. XX century characterized by the creation of many brands of magnetic materials, the improvement of methods for their magnetization and the creation of a certain crystal structure.

In 1906, a US patent was issued for a hard-coated magnetic disk. The coercive force of the magnetic materials used for recording was low, which, in combination with high residual inductance, large thickness of the working layer and low manufacturability, led to the fact that the idea of magnetic recording was practically forgotten until the 20s century.

In 1925 in the USSR and in 1928 in Germany, recording media were developed, which are flexible paper or plastic tape on which a layer of powder containing carbonyl iron is applied.

In the 20s of the last century. magnetic materials are created based on alloys of iron with nickel (permaloid) and iron with cobalt (permendura). For use at high frequencies, ferrocards are available, which are laminated material made of paper coated with varnish with particles of iron powder distributed in it.

In 1928, an iron powder consisting of micron-sized particles was obtained in Germany, which was proposed to be used as a filler in the manufacture of cores in the form of rings and rods.The first application of permalloy in the construction of a telegraph relay belongs to the same period.

Permalloy and permendyur include expensive components — nickel and cobalt, which is why alternative materials have been developed in countries lacking suitable raw materials.

In 1935, H. Masumoto (Japan) created an alloy based on iron alloyed with silicon and aluminum (alcifer).

In the 1930s. iron-nickel-aluminum alloys (YUNDK) appeared, which had high (at that time) values of coercive force and specific magnetic energy. The industrial production of magnets based on such alloys began in the 1940s.

At the same time, ferrites of various varieties were developed and nickel-zinc and manganese-zinc ferrites were produced. This decade also included the development and use of magneto-dielectrics based on permaloid and carbonyl iron powders.

During the same years, developments were proposed that formed the basis for the improvement of magnetic recording. In 1935, a device called the Magnetofon-K1 was created in Germany, in which a magnetic tape was used to record sound, the working layer of which consisted of magnetite.

In 1939, F. Matthias (IG Farben / BASF) developed a multi-layer tape consisting of a backing, adhesive and gamma iron oxide. Ring magnetic heads with a magnetic core based on permaloid have been created for playback and recording.

In the 1940s. the development of radar technology led to studies of the interaction of an electromagnetic wave with magnetized ferrite. In 1949, W. Hewitt observed the phenomenon of ferromagnetic resonance in ferrites. In the early 1950s.Ferrite-based auxiliary power supplies are beginning to be produced.

In the 1950s. In Japan, commercial production of hard magnetic ferrites began, which were cheaper than YUNDK alloys, but inferior to them in terms of specific magnetic energy. The beginning of the use of magnetic tapes to store information in computers and to record television broadcasts dates back to the same period.

In the 60s of the last century. the development of magnetic materials based on compounds of cobalt with yttrium and samarium is underway, which in the next decade will lead to the industrial implementation and improvement of similar materials of various types.

In the 70s of the last century. the development of technologies for the production of thin magnetic films led to their widespread use for recording and storing information.

In the 80s of the last century. commercial production of sintered magnets based on the NdFeB system begins. Around the same time, the production of amorphous, and a little later, nanocrystalline magnetic alloys began, which became an alternative to permaloid, and in some cases, to electrical steels.

The discovery in 1985 of the giant magnetoresistance effect in multilayer films containing nanometer-thick magnetic layers laid the foundation for a new direction in electronics - spin electronics (spintronics).

In the 90s of the last century. Compounds based on the SmFeN system were added to the spectrum of composite hard magnetic materials and in 1995 the magnetoresistance tunneling effect was discovered.

In 2005the giant tunnel magnetoresistance effect was discovered. After that, sensors based on the effect of giant and tunnel magnetoresistance were developed and put into production, intended for use in combined recording / reproduction heads of hard magnetic disks, in magnetic tape devices, etc. Random access memory devices were also created.

In 2006, the industrial production of magnetic disks for perpendicular magnetic recording began. The development of science, the development of new technologies and equipment make it possible not only to create new materials, but also to improve the characteristics of previously created ones.

The beginning of the XXI century can be characterized by the following main areas of research related to the use of magnetic materials:

-

in electronics — reducing the size of equipment due to the introduction of flat and thin-film devices;

-

in the development of permanent magnets — replacement of electromagnets in various devices;

-

in storage devices — reducing the size of the memory cell and increasing the speed;

-

in electromagnetic shielding — increasing the efficiency of electromagnetic shields in a wide frequency range while reducing their thickness;

-

in power supplies — expanding the limits of the frequency range in which magnetic materials are used;

-

in liquid inhomogeneous media with magnetic particles — expanding the areas of their effective application;

-

in the development and creation of sensors of different types — expanding the range and improving technical characteristics (especially sensitivity) through the use of new materials and technologies.