Classification and basic characteristics of magnetic materials

All substances in nature are magnetic in the sense that they have certain magnetic properties and interact in a certain way with an external magnetic field.

The materials used in the technology are called magnetic, taking into account their magnetic properties. The magnetic properties of the substance depend on the magnetic properties of microparticles, the structure of atoms and molecules.

Classification of magnetic materials

Magnetic materials are divided into weakly magnetic and strongly magnetic.

Being weakly magnetic include diamagnets and paramagnets.

Strong magnetic - ferromagnets, which in turn can be magnetically soft and magnetically hard. Formally, the difference in magnetic properties of materials can be characterized by the relative magnetic permeability.

Diamagnets refer to materials whose atoms (ions) have no resultant magnetic moment. Externally, diamagnets manifest themselves by being repelled by the magnetic field. These include zinc, copper, gold, mercury and other materials.

Diamagnets refer to materials whose atoms (ions) have no resultant magnetic moment. Externally, diamagnets manifest themselves by being repelled by the magnetic field. These include zinc, copper, gold, mercury and other materials.

Paramagnets are called materials, the atoms (ions) of which result in a magnetic moment independent of the external magnetic field. Externally, paramagnets manifest through attraction inhomogeneous magnetic field… These include aluminum, platinum, nickel and other materials.

Ferromagnets are called materials in which their own (internal) magnetic field can be hundreds and thousands of times higher than the external magnetic field that caused it.

Each ferromagnetic body is divided into regions — small areas of spontaneous (spontaneous) magnetization. In the absence of an external magnetic field, the directions of the magnetizing vectors of different regions do not coincide, and the resulting magnetization of the whole body can be zero.

There are three types of ferromagnetic magnetization processes:

1. The process of reversible displacement of magnetic domains. In this case, there is a displacement of the boundaries of the regions oriented closest to the direction of the external field. When the field is removed, the domains shift in the opposite direction. The region of reversible domain displacement is located at the initial part of the magnetization curve.

1. The process of reversible displacement of magnetic domains. In this case, there is a displacement of the boundaries of the regions oriented closest to the direction of the external field. When the field is removed, the domains shift in the opposite direction. The region of reversible domain displacement is located at the initial part of the magnetization curve.

2. The process of irreversible displacement of magnetic domains. In this case, the displacement of the boundaries between magnetic domains is not removed with decreasing magnetic field. The initial positions of the domains can be achieved in the magnetization reversal process.

Irreversible displacement of domain boundaries leads to the appearance magnetic hysteresis — the lag of magnetic induction from field strength.

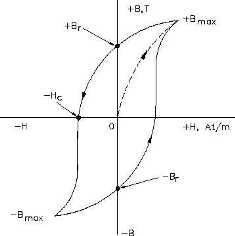

3. Domain rotation processes. In this case, the completion of the displacement processes of the domain boundaries leads to technical saturation of the material.In the saturation region, all regions rotate in the direction of the field. The hysteresis loop that reaches the saturation region is called the boundary.

The limiting hysteresis circuit has the following characteristics: Bmax — saturation induction; Br — residual induction; Hc — retarding (coercive) force.

Materials with low Hc values (narrow hysteresis cycle) and high magnetic permeability are called soft magnetic.

Materials with high values of Hc (wide hysteresis loop) and low magnetic permeability are called magnetically hard materials.

During magnetization of a ferromagnet in alternating magnetic fields, thermal energy losses are always observed, that is, the material heats up. These losses are due to hysteresis and eddy current losses… The hysteresis loss is proportional to the area of the hysteresis loop. Eddy current losses depend on the electrical resistance of the ferromagnet. The higher the resistance, the lower the eddy current losses.

Magnetically soft and magnetically hard materials

Soft magnetic materials include:

1. Technically pure iron (electric low carbon steel).

2. Electrotechnical silicon steels.

3. Iron-nickel and iron-cobalt alloys.

4. Soft magnetic ferrites.

The magnetic properties of low-carbon steel (technically pure iron) depend on the content of impurities, distortion of the crystal lattice due to deformation, grain size and heat treatment. Due to its low resistivity, commercially pure iron is used quite rarely in electrical engineering, mainly for DC magnetic flux circuits.

Electrotechnical silicon steel is the main magnetic material for mass consumption. It is an iron-silicon alloy. Alloying with silicon allows you to reduce the coercive force and increase the resistance, that is, reduce eddy current losses.

Electrotechnical silicon steel is the main magnetic material for mass consumption. It is an iron-silicon alloy. Alloying with silicon allows you to reduce the coercive force and increase the resistance, that is, reduce eddy current losses.

Sheet electrical steel, supplied in individual sheets or coils, and strip steel, supplied only in coils, are semi-finished products intended for the manufacture of magnetic circuits (core).

Magnetic cores are formed either from individual plates obtained by stamping or cutting, or by winding from strips.

They are called nickel-iron permaloid alloys... They have a large initial magnetic permeability in the region of weak magnetic fields. Permalloy is used for cores of small power transformers, chokes and relays.

Ferrites are magnetic ceramics with a high resistance, 1010 times higher than that of iron. Ferrites are used in high-frequency circuits because their magnetic permeability practically does not decrease with increasing frequency.

The disadvantages of ferrites are their low saturation induction and low mechanical strength. Therefore, ferrites are commonly used in low voltage electronics.

Magnetically hard materials include:

1. Cast magnetically hard materials based on Fe-Ni-Al alloys.

2. Powdered solid magnetic materials obtained by pressing powders with subsequent heat treatment.

3. Hard magnetic ferrites. Magnetically hard materials are materials for permanent magnetsused in electric motors and other electrical devices that require a permanent magnetic field.