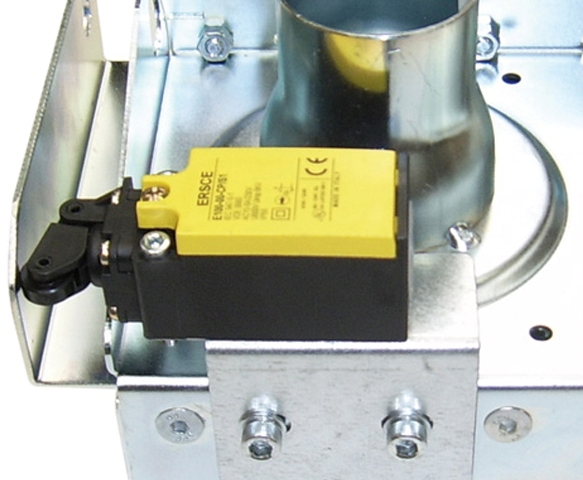

Comparison of contact and non-contact travel switches

In industrial automation, circuits are widely used travel (position) switches and switches multiple designs designed to control the position of various production mechanisms and based on the transformation of the movement of these mechanisms in an electrical signal.

Position switches can also be used to perform functions other than position control of production mechanisms, for example, control of rotation angle, level, weight pressure, etc.

Direction switches are devices with a discrete action, working on the principle of increase, that is, they react only to a change in the position of the controlled mechanism. The output signal of the way switches is an ambiguous function of the movement of the mechanism from a given initial position.

Types of road switches

Depending on the principles of positional switching, the switching method is subdivided into:

-

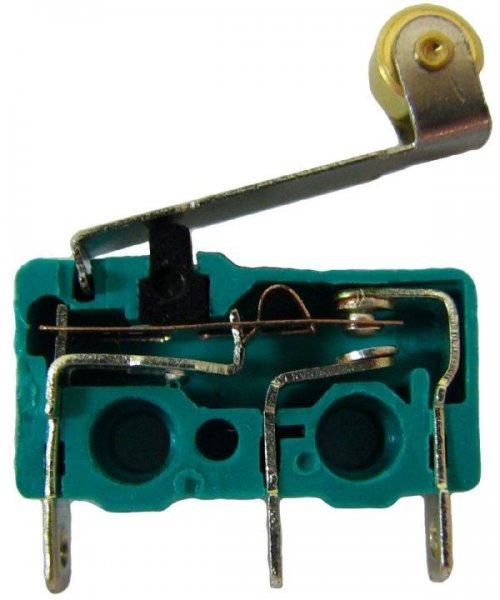

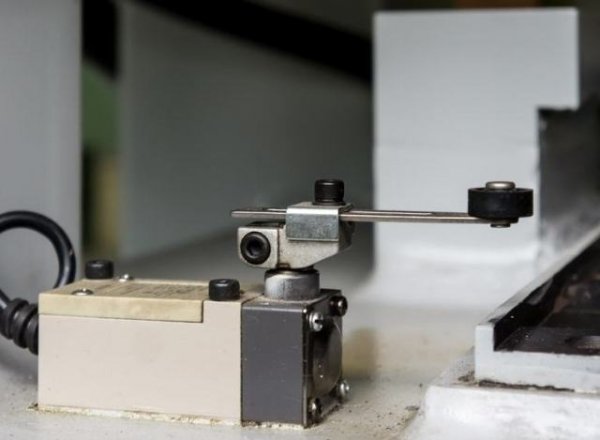

mechanical contact made with switching contacts and contact-sensitive elements;

-

static contact (magnetomechanical), the sensitive element of which is non-contact, and the switching element is a contact;

-

static contactless, sensitive and switching elements from which contactless are made.

In the contact nature of the "switching - stop" node, that is, in the contact nature of the connection of the driving element (input control signal) with the sensitive element, this node is called mechanical, and in non-contact - static.

Depending on the design, switches can be combined or separated. In the first case, the sensitive and switching elements are placed in one housing and are structurally executed as a whole. In the second, the sensitive element can be located at a distance of several tens and hundreds of meters from the switch.

The distortion of the magnetic field of the path switch is achieved by changing the parameters magnetic circuit sensitive element. Variable parameters can be the active surface area and the size of the air gap as well magnetic permeability magnetic circuit.

Currently, the field of application of mechanical contact position switches in industrial automation is narrowing, and the question arises about the uselessness of position switches of this type for the purpose of building automatic control systems.

The latter is caused by the following:

-

The complexity of the design of the switch-stop assembly, due to the strictness of the requirements regarding the limits of permissible fluctuations of a number of parameters, which causes significant difficulties in its manufacture and adjustment.

-

The relatively high criticality of the accuracy characteristics of this device to the influence of destabilizing factors (wear of contact surfaces, looseness of fasteners, misalignment of moving elements, etc.).

A number of design solutions of mechanisms cannot be implemented at all based on mechanical contact switches. These include mechanisms that require high allowable levels of speed and frequency of motion switches.

If the required speed of operation of the road switch can be reduced due to additional kinematic links of the mechanism, which, among other things, deteriorate the quality characteristics of the control system (in particular, accuracy parameters), then the permissible operating frequency (resolution) does not may be increased by structural complications.

See also: Installation of limit switches and switches

In this case, what is the reason for the widespread use of the mechanical contact principle of position switching? The answer to this question should be sought in two aspects: in the existing principles of construction of automatic control systems and in the advantages of the contact path switch circuit.

Advantages of contact path switches

Mechanical contact switches, usually implemented with a multi-circuit output, are characterized by the following advantages:

-

high switching ratio;

-

high specific control power (the ratio of the included power to the overall dimensions);

-

universality, that is, the ability to switch both direct and alternating current circuits;

-

large range of included voltages;

-

negligible internal energy consumption (small value of transient resistance of the contacts in the closed state);

-

low dependence of accuracy and stability of operation on changes in controlled power.

Disadvantages of contact path switches

The principle of mechanical contact of these devices often does not allow meeting the increased requirements for reliability, durability and accuracy of automation systems. In addition, mechanical contact switches are very sensitive to the effects of various climatic factors (especially at low temperatures).

Mechanical contact switches are characterized by limited permissible levels of maximum and minimum movement speed of the switching stop, which are in the range of 0.3 — 30 m / min, and increasing the speed of the switching stop above the permissible level leads to a sharp decrease in mechanical durability on the switch.

In such switches, the permissible deviations of the direction of action of the switching force relative to the axis of the lever are very small, and exceeding them leads to mechanical damage, especially in switches with a front pull rod.

In order to obtain relay output characteristics (control characteristics), trigger-spring devices are provided in the design of such switches. The required degree of relay output characteristics is achieved at the cost of a significant reduction in switch durability due to the large dynamic stresses occurring in the trigger at the time of actuation.

In mechanical momentary contact switches, the width of the hysteresis loop (stroke differential) of the output characteristic reaches a significant value, which is completely unacceptable for a number of technological processes due to an unproductive increase in the duration of the processing cycle.

Reducing the difference in the travel of these derailleurs is related to either increasing the complexity of their design or increasing their size. Additionally, in some cases significant mechanical forces are required to actuate mechanical contact switches.

Advantages and disadvantages of proximity switches

The circumstances listed above lead to the need to develop devices that are devoid of the mentioned disadvantages and at the same time are capable of performing similar functions. Such devices are proximity switches, the benefits of which include:

-

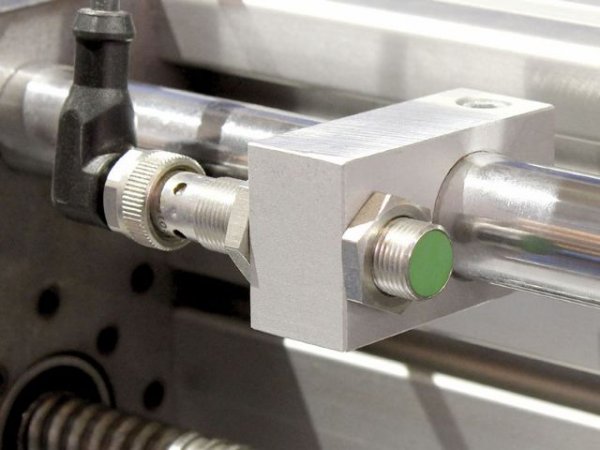

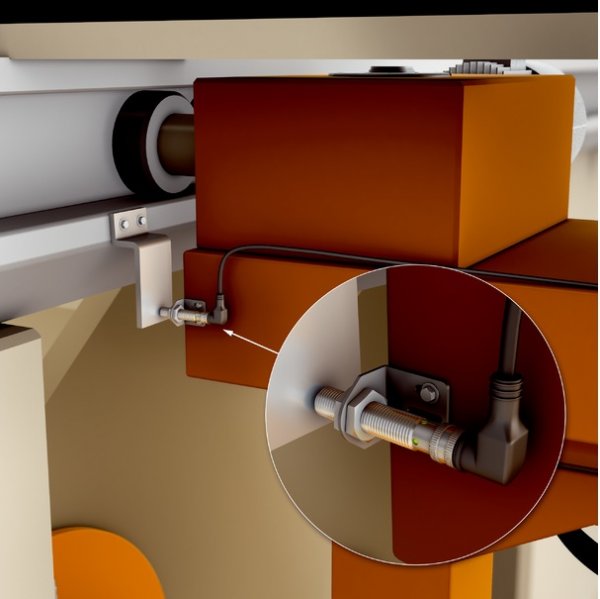

significant durability with high reliability and high permissible operating frequency;

-

no need for mechanical effort when actuating, low sensitivity to vibrations, acceleration, etc.;

-

insignificant sensitivity of parameters to changes in a relatively wide range of external conditions;

-

improving the conditions of operational services.

Due to the low level of feedback of the proximity switch, a significant simplification of the stop switch construction is achieved while maintaining a high stability over time of the accuracy characteristics. In addition, the absence of electrical and mechanical contacts ensures fire and explosion safety of these devices, which significantly expands the area of their possible application.

One of the significant disadvantages of contactless limit switches is the complexity of implementing many design modifications that are easily implemented in mechanical contact limit switches.

Proximity switch device

The principle of operation of static non-contact path switches of the parametric type is based on the use of distortion of the magnetic or electric field created by the sensitive element when a driving element appears in its area, as a result of which an unbalanced state occurs in the electrical circuit of the switch and the output device is triggered.

Static proximity switches are most often made with a single output circuit, and in some switches the actuation is accompanied by the appearance of a signal at the output (direct switching effect), in others - by disappearance (reverse switching effect), which is equivalent to closing and the opening contacts of the mechanical contact paths respectively.

If there is an amplifying element in the relay-mode proximity switch circuit, the output parameter of the sensing element can be in continuous functional dependence of the controlled motion.

Currently, numerous design modifications of non-contact travel switches are used, differing in the level of sensitivity (the size of the working gap), the location of the slot or the plane of the sensitive element relative to the mounting plane, the direction of the leading wires, the number of steps of the sensing element (for design with slots), the depth of the slot, the length of the connecting wires, the level of the supply voltage, the nature of the protection against environmental influences, etc.

The possibilities of using contactless motion switches are determined by the parameters of their electrical and mechanical characteristics.

Electrical parameters include:

- the nature of the output signal and the number of output circuits;

- consumption and output power;

- shape of the output signal; switching coefficient for resistance and voltage (for transformer-type switches);

- timing characteristics (trigger and release times) and firing frequency (resolution);

- the levels and shape of the supply voltage, as well as the permissible limits of their deviations.

Mechanical performance parameters include:

- sensitivity (size of working gap),

- dimensions and connection dimensions;

- accuracy characteristics (major and additional errors) and stroke differential;

- installation characteristics (types of switching brakes and how they are installed, the level of feedback, how to mount and install the switch);

- the noise protection level.

For more information on the Proximity Switch Device and Switches see here: Non-contact sensors for the position of mechanisms

Ivenski Yu. N.Contactless travel switches in industrial automation