How the solenoid valve works

The solenoid valve serves as an automatic shut-off device to control the movement of liquid or gaseous media in pipelines for various purposes. The flux here varies due to the action of an electromagnetic coil which is triggered at the appropriate times.

Such valves are widely used both in domestic communications and in industrial facilities. They can work in a wide temperature range and allow you to regulate water supply and sewage communications, they are used in oil refineries and chemical plants, in the agricultural sector (irrigation systems), in filtration systems, etc.

The main structural elements of electromagnetic (or solenoid) of the valve are: body, coil, seal and functional elements. The body can be made of stainless steel, brass, cast iron or a suitable chemical polymer.

A coil with a core and winding of high-strength technical copper is mounted in (on) the housing. Rubber, Teflon, fluoroplastic, silicone, or heat-resistant rubber can act as a sealant that provides tightness.The valve contains the following functional elements: piston (displacer), spring and steel stem.

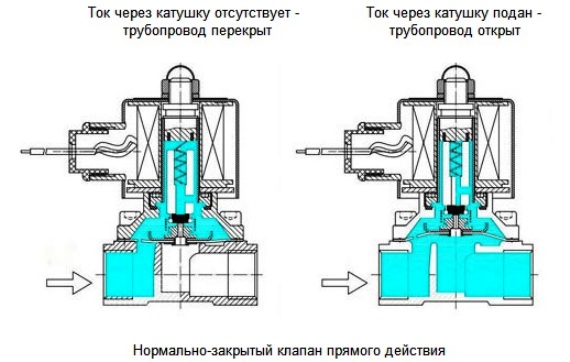

The main thing in the operation of the solenoid valve is the control of the solenoid coil… When there is no current in the coil, the valve block is actuated by a spring in the seat and the flow orifice can be opened or closed, depending on the type of valve.

When an electrical voltage (DC or AC, depending on the valve design) is applied to the coil, the core is drawn into the coil, thereby closing or opening the flow orifice. Depending on the type of valve, some characteristics of some of its elements may vary.

According to the type of initial working position, the solenoid valves are: normally open when the closing element leaves an open hole in the absence of current through the coil; normally closed, when in the absence of current through the coil, the closing element closes the flow opening; bistable, when the valve can switch to an open or closed state under the action of a switching current pulse.

By way of action valves are divided into: direct-acting valves, when the state of the shut-off valves is changed directly by the movement of the coil core when voltage is applied to its terminals; and indirect valves, where the process fluid participates in the closing or opening process along with the movement of the control valve connected to the coil.

Solenoid valves are produced in different versions depending on the type of attachment to the pipeline. There are coupling valves that are installed directly in the pipeline on the thread.

There are flanged valves, which are connected to the pipe using a pair of side flanges with gaskets, there are mounting holes in the flanges (for bolts or studs). Union valves are used for small bores and bore pipes, while flanged valves are used for pipes with larger bores.

The advantages of solenoid valves as shut-off valves are obvious. First, it opens up huge opportunities for remote control and automation of processes for regulating the flow of various media in pipelines.

Of course, the high speed of solenoid valves cannot be compared with manual analogues, which in one way or another are becoming a thing of the past in many industries.

Solenoid valves are compact, lightweight, easy to maintain and have a long service life.

See also: Motorized valves in automation systems