Asynchronous executive motors

Asynchronous actuator motors are used in automatic control systems to control and regulate various devices.

Asynchronous actuator motors start working when they are given an electrical signal, which they convert into a certain angle of rotation of the shaft or its rotation. Removal of the signal results in an immediate transition of the rotor of the running engine to a stationary state without the use of braking devices. The operation of such motors continues all the time under transient conditions, as a result of which the frequency of rotation of the rotor often does not reach a stationary value with a short signal. Frequent starts, changes of direction and stops also contribute to this.

By design, executive motors are asynchronous machines with a two-phase stator winding, made so that the magnetic axes of its two phases are displaced in space relative to each other, and not at an angle of 90 degrees.

One of the phases of the stator winding is the field winding and has leads to the terminals labeled C1 and C2.The other, acting as a control coil, has wires connected to the terminals labeled U1 and U2.

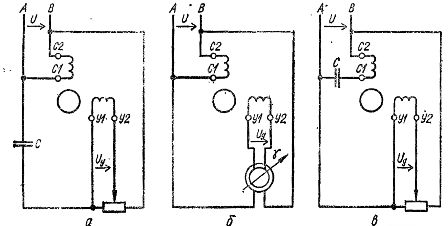

Both phases of the stator winding are supplied with corresponding alternating voltages of the same frequency. So the excitation coil circuit is connected to the supply network with a constant voltage U, and a signal is supplied to the control coil circuit in the form of a control voltage Uy (Fig. 1, a, b, c).

Rice. 1. Schemes for switching on asynchronous executive motors during control: a — amplitude, b — phase, c — amplitude phase.

As a result, corresponding currents arise in both phases of the stator winding, which, due to the included phase-shifting elements in the form of capacitors or a phase regulator, are shifted relative to each other in time, which leads to the excitation of an elliptical rotating magnetic field, which includes the squirrel cage rotor.

When changing the operating modes of the motor, the elliptic rotating magnetic field in limiting cases becomes alternating with a fixed axis of symmetry or circular rotating, which affects the properties of the motor.

When changing the operating modes of the motor, the elliptic rotating magnetic field in limiting cases becomes alternating with a fixed axis of symmetry or circular rotating, which affects the properties of the motor.

The starting, speed regulation and stopping of the executive motors are determined by the conditions for the formation of the magnetic field by means of amplitude, phase and amplitude-phase control.

In amplitude control, the voltage U at the terminals of the excitation coil is kept unchanged and only the amplitude of the voltage Uy changes. The phase shift between these voltages, thanks to the disconnected capacitor, is 90 ° (Fig. 1, a).

Phase control is characterized by the fact that the voltages U and Uy remain unchanged, and the phase shift between them is adjusted by rotating the rotor of the phase regulator (Fig. 1, b).

With amplitude-phase control, although only the amplitude of the voltage Uy is regulated, but at the same time, due to the presence of a capacitor in the excitation circuit and the electromagnetic interaction of the phases of the stator winding, there is a simultaneous change in the phase of the voltage at the winding terminals for excitation and the phase shift between this voltage and the voltage from the terminals of the control coil (Fig. 1, c).

Sometimes, in addition to the capacitor in the field winding circuit, a capacitor in the control winding circuit is provided, which compensates for the reactive magnetizing force, reduces energy losses and improves the mechanical characteristics of the induction motor.

In amplitude control, a circular rotating magnetic field is observed at a nominal signal regardless of the rotor speed, and when it decreases, it becomes elliptical. In the case of phase control, a circular rotating magnetic field is excited only with a nominal signal and a phase shift between voltages U and Uy, equal to 90 ° regardless of the rotor speed, and with a different phase shift becomes elliptical. In amplitude-phase control, a circular rotating magnetic field exists in only one mode — at a nominal signal at the time of starting the motor, and then, when the rotor accelerates, it becomes elliptical.

In all control methods, the speed of the rotor is controlled by changing the nature of the rotating magnetic field, and the direction of rotation of the rotor is changed by changing the phase of the voltage applied to the terminals of the control coil by 180 °.

Specific requirements are imposed on asynchronous executive motors in terms of the lack of self-propelled power providing a wide range of rotor speed control, speed, large starting torque and low control power with relative preservation of the linearity of their characteristics.

Specific requirements are imposed on asynchronous executive motors in terms of the lack of self-propelled power providing a wide range of rotor speed control, speed, large starting torque and low control power with relative preservation of the linearity of their characteristics.

Self-propelled asynchronous executive motors are manifested in the form of spontaneous rotation of the rotor in the absence of a control signal. It is caused either by an insufficiently large active resistance of the rotor winding-methodically self-propelled, or by poor performance of the motor itself-technologically self-propelled.

The first is eliminated in the design of motors, which provides for the production of a rotor with increased winding resistance and critical slip scr = 2 — 4, which, in addition, provides a wide stable range of rotor speed control, and the second - high-quality production of magnetic circuits and machine coils with careful assembly.

Since asynchronous executive motors with a short-circuited rotor with increased active resistance are characterized by a low speed characterized by an electromechanical time constant — the time when the rotor picks up speed from zero to half of the synchronous speed — Tm = 0.2 — 1.5 s, then in automatic installations preference for control is given to executive motors with a hollow non-magnetic rotor, in which the electromechanical time constant has a lower value — Tm = 0.01 — 0.15 s.

High-speed hollow non-magnetic rotor induction executive motors have both an external stator with a magnetic circuit of conventional construction and a two-phase winding with phases acting as excitation and control windings, and an internal stator in the form of a laminated ferromagnetic hollow cylinder mounted on the engine bearing shield.

The surfaces of the stators are separated by an air gap, which in the radial direction has a size of 0.4 — 1.5 mm. In the air gap, there is an aluminum alloy glass with a wall thickness of 0.2 — 1 mm, fixed on the motor shaft. The idle current of asynchronous motors with a hollow non-magnetic rotor is large and reaches 0.9 Aznom, and the nominal efficiency = 0.2 — 0.4.

In automation and telemechanics installations, motors with a hollow ferromagnetic rotor with a wall thickness of 0.5 — 3 mm are used. In these machines, used as executive and auxiliary motors, there is no internal stator, and the rotor is mounted on one pressed or two end metal plugs.

The air gap between the surfaces of the stator and the rotor in the radial direction is only 0.2 — 0.3 mm.

The air gap between the surfaces of the stator and the rotor in the radial direction is only 0.2 — 0.3 mm.

The mechanical characteristics of motors with a hollow ferromagnetic rotor are closer to linear than the characteristics of motors with a conventional squirrel-wound rotor, as well as with a rotor made in the form of a hollow non-magnetic cylinder.

Sometimes the outer surface of a hollow ferromagnetic rotor is covered with a layer of copper with a thickness of 0.05 - 0.10 mm, and its end surfaces with a layer of copper up to 1 mm to increase the rated power and torque of the motor, but its efficiency decreases somewhat.

A significant disadvantage of motors with a hollow ferromagnetic rotor is the one-sided sticking of the rotor to the magnetic circuit of the stator due to the unevenness of the air gap, which does not occur in machines with a hollow non-magnetic rotor. Hollow ferromagnetic rotor motors are not self-propelled; they operate stably over the speed range from zero to synchronous rotor speed.

Asynchronous executive motors with a massive ferromagnetic rotor, made in the form of a steel or cast iron cylinder without a winding, are distinguished by their simplicity of design, high strength, high starting torque, stability of operation at a given speed, and can be used at very high revolutions on the rotor.

There are inverted motors with a massive ferromagnetic rotor, which is made in the form of an external rotating part.

Asynchronous executive motors are produced for rated power from fractions to several hundred watts and are designed for power from variable voltage sources with a frequency of 50 Hz, as well as with increased frequencies up to 1000 Hz and more.

Read also: Selsyns: purpose, device, principle of action