Repair of brake electromagnets and electrohydraulic thrusters

Brake electromagnets are widely used in the enterprises of most leading industries and in transport. They are designed to quickly stop the mechanisms, reliably hold the lifted load, reduce the time of stopping the mechanisms and are used in bridge cranes, freight elevators, mine hoists, etc.

Brake electromagnets are widely used in the enterprises of most leading industries and in transport. They are designed to quickly stop the mechanisms, reliably hold the lifted load, reduce the time of stopping the mechanisms and are used in bridge cranes, freight elevators, mine hoists, etc.

There are many designs of brake solenoids, including short- and long-stroke, single-phase and three-phase DC and AC brake solenoids.

Regardless of the size of the stroke, the phase and the type of current, brake electromagnets have essentially the same device, differing from each other mainly in the construction of individual parts, determined by the purpose of the electromagnet and its role in the mechanism control scheme.

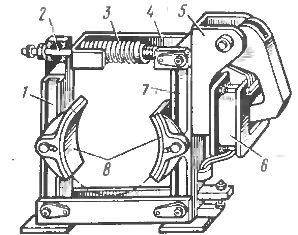

A short-stroke single-phase brake electromagnet (Fig. 1, a) consists of a coil, which is connected in parallel with the stator winding of the electric motor, and a system of levers.The winding of the coil 6 of the brake electromagnet 5, as a rule, is made of wire with enamel or enamel and additional cotton insulation.

Rice. 1. The device of the brake electromagnet: 1,7 — levers, 2 — hairpin, 3 — spring, 4 — bracket, 5 — electromagnet, 6 — coil, 8 — brake pads

When the brake electromagnet is de-energized with a parallel-connected coil, the accumulated magnetic field energy is quenched using a discharge resistor. The brake solenoid is included in the mechanism control system, so the coil is bled and the braking action of the solenoid occurs simultaneously with the stop of the corresponding electric motor.

At the moment of turning off the electric motor, the coil b of the electromagnet is turned off at the same time. The armature of the electromagnet, falling, ceases to hold the tensioned spring, which by compression acts on the levers 1 and 7. Bringing the levers together with the pads 8 mounted on them, the armature tightens the washer located between the pads and thus stops, suppresses the inertia of rotation of the electric motor or the movement of the mechanism.

Periodic inspection and repair brake solenoids and electro-hydraulic thrusters carried out simultaneously with the inspection and repair of the mechanical part of the crane brakes.

The frequency of these operations depends on the mode of operation of the crane mechanisms: with heavy loads, they are carried out more often (daily inspection, inspection and adjustment), with light loads - less often.

The most typical malfunctions of brake electromagnets are the following:

1. The armature of an electromagnet is not attracted when its coil is connected to the mains.

If the mechanical part of the brake is in good condition, this malfunction can be caused by one of the following reasons:

-

insufficient voltage of the solenoid coil (below 90% for DC electromagnets KMP parallel connection to three-phase electromagnets KMT AC, below 85% for VM electromagnets parallel connection),

-

for DC electromagnets in series — low load current (motor armature circuit),

-

for direct current electromagnets — abnormally large armature stroke, more than the value of the passport,

-

incorrect inclusion of the coils of three-phase electromagnets, for example, their opposite inclusion, accompanied by significant noise to a rapid increase in the heating of the coils,

-

interruption or short circuit in the coil (in the first case, the coil does not develop any traction force, and in the second, an overestimated and uneven heating of the coil is observed).

2. "Sticking" of the armature of the electromagnet after disconnecting its coil:

-

thickening of too much grease in cold weather (sticking in the brake mechanism),

-

wear of the non-magnetic seal for DC electromagnets or crushing of the magnetic circuit joint (for MO series electromagnets), resulting in the disappearance of the gap between the upper bars of the yoke and the armature (this gap must be at least 0.5 mm),

-

for long-stroke DC solenoids of the KMP and VM series — wear of the guide sleeve, due to which the armature begins to touch the body or cover.

3. Unusually loud noise, buzzing of switched-on AC electromagnets:

-

the anchor is not fully retracted,

-

incorrect installation or adjustment of the magnetic circuit of the electromagnet,

-

short circuit failure of MO series single phase electromagnet.

4. Abnormally high temperature solenoid coils:

-

overestimated voltage in the electromagnet of a parallel connection or overestimated current in the electromagnets of a series connection,

-

for alternating current electromagnets — incomplete armature attraction or turn loop in the coil.

5. Failure of the electro-hydraulic thruster connected to the network:

-

breakage of wires connecting the electric motor to the grid,

-

sticking of the rods or piston of the electrohydraulic pusher, sticking in the brake joints,

-

excessive voltage drop (below 90% of nominal).