Electro-hydraulic thrusters

An electro-hydraulic pusher is a complex device consisting of an electric motor, a centrifugal pump and a hydraulic cylinder with a piston. The most widespread are the serial single-rod electro-hydraulic thrusters with traction forces from 160 to 1600 N.

An electro-hydraulic pusher is a complex device consisting of an electric motor, a centrifugal pump and a hydraulic cylinder with a piston. The most widespread are the serial single-rod electro-hydraulic thrusters with traction forces from 160 to 1600 N.

Electrohydraulic brakes with movable mechanisms have the following advantages over brakes with electromagnets: increased durability (several times greater), no shocks when switching on and off, smoothness of the braking process, significantly less weight of the electrohydraulic pusher (4 — 5 times compared to the brake electromagnet of the KMT series), lower consumption of energy (by 20 — 25%), significantly lower consumption of the winding wire (about 10 times), jamming of the braking device does not lead to harmful consequences (for AC brakes in this case they fail due to overheating of the coil) .

Series-produced electro-hydraulic thrusters are designed for continuous operation and allow up to 100 starts per hour. With a PV reduction of up to 60%, electric hydraulic thrusters allow 700 actuations per hour.

For crane installations, brake devices of the TKTG series with electro-hydraulic pushers of types TE-16, TE-25, TE-30, TE-50, TE-80, TE-160 with nominal forces of 160, 250 , 500, 800 and 1600 respectively N.

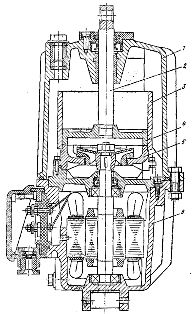

Rice. 1. TE series electro-hydraulic thruster

For the TE electrohydraulic pusher, when the electric motor 6 attached to the pusher body 1 is turned on, the centrifugal pump pumps the working fluid under the piston 4 that moves in the cylinder 3 and creates excess pressure. In this connection, the piston with the rod 2 rises, overcoming the external load applied to the rod.

The rod acts on the brake device and the brake is released. The liquid above the piston flows into the suction area of the pump.

The piston remains in the up position while the engine is running. When the electric motor is turned off, the pump stops working, the excess pressure disappears, and the piston with the rod under the action of an external load (the brake spring) and its own gravity falls to its original position, which leads to a stop. The working fluid displaced by the piston from the cylinder flows through the impeller and channels into the cavity above the piston.

The piston remains in the up position while the engine is running. When the electric motor is turned off, the pump stops working, the excess pressure disappears, and the piston with the rod under the action of an external load (the brake spring) and its own gravity falls to its original position, which leads to a stop. The working fluid displaced by the piston from the cylinder flows through the impeller and channels into the cavity above the piston.

It should be noted that the electric motor of the TE-TE-50, TE-80 series is not filled with working fluid.

The disadvantage of electrohydraulic pushers compared to brake electromagnets is their relatively long actuation time (rod raising time is 0.35 to 1.5 s, rod lowering time is 0.28 to 1.2 s). In addition, electro-hydraulic thrusters cannot be operated without periodic replacement of the working fluid for location category Y, and are also unsuitable for category HL2.However, the above advantages of electro-hydraulic thrusters have led to their widespread use for crane mechanisms.

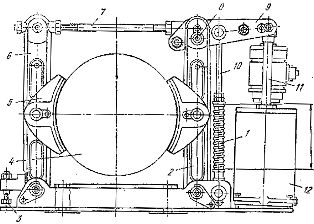

In fig. 2 shows a spring shoe brake with an electro-hydraulic tap.

Rice. 2. Brake for a crane with an electrohydraulic pusher: 1 — spring, 2, 6 and 9 — levers, 3 — adjusting bolt, 4 brake washer, 5 — brake linings, 7 — brake rod, 8 — pin, 10 — pulling rod, 11 — push rod, 12 — pusher

Rice. 3. Shoe brake TKG-160 with electro-hydraulic pusher