Braking methods for electric motors

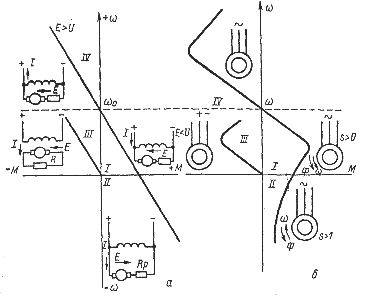

Electric motors in an electric drive can quickly stop the production mechanism or hold a certain speed at a positive moment of the working machine. In such a case, the motor becomes a generator and operates in one of the braking modes: opposite, dynamic, restorative (see Fig. 1) depending on the method of excitation.

Electric motors in an electric drive can quickly stop the production mechanism or hold a certain speed at a positive moment of the working machine. In such a case, the motor becomes a generator and operates in one of the braking modes: opposite, dynamic, restorative (see Fig. 1) depending on the method of excitation.

Stopping the electric drive by switching the windings of the phases of the electric motor to get the rotation of the field in the opposite direction (reverse stop) are used when it is necessary to quickly stop the machine device. In this case, by inertia the rotor rotates towards the magnetic flux, engine slippage becomes more than one, and the moment becomes negative.

In a DC motor, to perform opposite braking, the connection of the ends of the armature windings is changed. In this case, the armature current and moment change direction.

In both cases, the effective voltage becomes large, therefore, in order to limit the current and torque, switching is done with the simultaneous inclusion of resistors in the armature or rotor circuit. The braking energy coming from the network is dissipated in the armature windings and in the resistors.

Dynamic braking characterized by the fact that the electric machine works as a generator (dynamo) with the dissipation of braking energy in the braking resistors and motor windings.

For dynamic braking, the armature of the DC motor is disconnected from the power source and connected to the resistance while the field winding remains energized, for induction motors, dynamic braking is achieved by applying direct current to the stator winding of the motor.

Direct current creates a stationary magnetic field. When the rotor rotates, an EMF is induced in its windings and a current appears. The interaction of the rotor current with a stationary magnetic field creates a braking torque. The value of the braking torque depends on the excitation current, the speed and the resistance of the rotor (armature) circuit.

In regenerative braking mode, the rotor (armature) of the electric motor connected to the network rotates at a speed greater than ωo. In this case, the current changes its direction, the electric machine becomes a generator working in parallel with the mains, the braking energy minus the losses is given to the mains.

Rice. 1. Switching on and mechanical characteristics of electric motors: independent excitation (a) and asynchronous (b) in modes: I — motor, II — opposition, III — dynamic braking, IV — generator with energy supply to the network.

Regenerative braking is used in cranes, to maintain speed when lowering the load, for testing and working under load of car and tractor engines, gearboxes, gearboxes under load, as well as when transitioning from a higher speed to a lower speed . multi-speed motors.