Power balances and increasing the efficiency of energy consumption modes of industrial enterprises

The role of electrical balances in the regulation of electricity consumption and their types

In the rationing of electricity consumption per unit of production, the leading role belongs to the electrical balances of the rationing objects and the electrical characteristics of technological units and operations. Electricity balances help to identify and correctly assess unnecessary losses of electricity and outline ways to save it.

In the rationing of electricity consumption per unit of production, the leading role belongs to the electrical balances of the rationing objects and the electrical characteristics of technological units and operations. Electricity balances help to identify and correctly assess unnecessary losses of electricity and outline ways to save it.

Electrical characteristics, expressing functional relationships between energy consumption elements and reasoned quantities characterizing raw materials, finished products and technological processes, allow to establish their optimal values and optimal specific energy consumption. Complementing each other, they are the basis on which progressive levels of electricity consumption can be reasonably calculated.

Power balances compiled by industrial enterprises, depending on the scale of the tasks to be solved, are divided into balances:

-

operations and units;

-

aggregate production processes of sections, departments, workshops and complex power plants (boilers, compressor rooms, etc.);

-

industrial enterprises.

By purpose, the balances are divided into actual, normalized, planned and prospective.

Actual electricity balances reflect actual electricity consumption indicators and the actual average annual level of energy consumption quality over the past year.

Normalized electrical balances reflect the most progressive, based on technical and economic calculations, the level of energy use by a unit, process, installation, workshop, enterprise. The basis for calculating such electrical balances is the electrical characteristics of the units and operations and the progressive specific norms for losses and useful consumption of electricity, compiled on their basis, corresponding to the optimal production conditions.

Planned electricity balances are the main form of annual energy consumption planning of the enterprise. Such balances are drawn up on the basis of a given production program and the current conditions of the enterprise in terms of technologies, production organization and power supply schemes, but take into account the specific changes in these conditions outlined by the technical plan of the enterprise for the next year.

Promising electricity balances compensate for long periods (five or more years) and reflect planned for these periods fundamental changes in technology, organization and volume of production.In the course of compiling promising electrical balances based on technical and economic calculations, they decide on the selection of new technological and electrical equipment with better electrical characteristics, design more rational power supply schemes, justify the construction of new, expansion and reconstruction of existing electrical installations and networks.

Structure and form

The electrical balance of the block, site, workshop, enterprise also consists of two parts — input and output, numerically equal to each other. The input part includes electricity received from a power source (external, own). The expenditure part includes the following expenditure items:

-

direct costs of the main technological process with the allocation of useful energy consumption for the production of products;

-

indirect electricity costs for the main technological process due to imperfection or violation of technological standards;

-

electricity costs for auxiliary needs (ventilation, lighting, transport in workshops, etc.);

-

electricity losses in the elements of the power supply system (lines, transformers, reactors, compensating devices and motors);

-

electricity supply to external users.

The electrical balances of the units are drawn up in the form of tables or diagrams relating the balance figures to the specified or actual operation of the unit or to the unit of the main product produced by the unit or the main raw material consumed. The capacity balances of objects, departments, workshops and enterprises are compiled in the form of tables expressing the balance positions in absolute or specific terms.

Compilation of electrical balances

The work on the compilation and analysis of power balances is focused on solving the problems of assessing the actual state and increasing the efficiency of power supply and energy consumption, quantifying the reserves for saving and energy losses, determining the requirements for improving the control of actual power consumption modes.

When drawing up electrical balances, the initial data are:

a) a list of electrical equipment with an indication of the passport parameters and characteristics,

b) materials from technological maps and a list of technological operations,

(c) performance power schemes,

d) the results of target measurements of electricity consumption and reactive power,

e) operating logs and reporting forms existing in the enterprise,

f) acts of previous studies of the electrical equipment, planning materials, financial departments and other services of the enterprise.

The electrical balance of a unit, technological unit, workshop, enterprise as a whole consists of input and output parts that are generally equal to each other.

Useful consumption (the amount of useful energy used) is defined as theoretically necessary for the implementation of the technological process, calculated, as a rule, according to the formulas given in the branch scientific and technical literature (for example, technological operations in woodworking, production of furniture, dishes, etc.) .

It is recommended to use the computational and experimental method more widely in the operating enterprises.When this method is used, the useful consumption is determined by subtracting from the actual energy consumption modified by the meter, its losses in networks, power transformers and electric drive.

Energy losses are not yet determined by the instrument, their value is determined by calculation.

Determination of energy losses in electrical networks

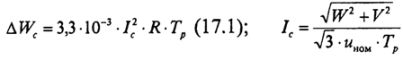

The amount of energy loss ΔWc kW-h in the network supplying an electrified block, site, workshop with energy consumption W, kW-h and reactive power consumption V, kvar-h

where Ic is the value of the consumed current, A, R is the resistance of the line, Ohm, Tr is the duration of operation of the energy-intensive equipment, h.

The factor 3.3 (1.1×3) takes into account the increase in resistance due to transient contacts, twisting of wires, increase in length due to overhead line deflection or cable bends.

In the absence of data on the actual value of Tp, the duration of operation of energy-intensive equipment can be determined with sufficient accuracy Tp = V /qh, where V is the reactive power consumption, kvarh, qh — hourly reactive power consumption.

Changes in the active power of the main industrial load of industrial enterprises - asynchronous motors are determined by the intensity of the process. Changes in reactive power are determined by it to a much lesser extent, therefore the estimate of Tp is made based on consumption reactive power… With repeated determination of ΔWc for a number of objects, it is recommended to automate all calculations.

Determination of energy losses in power transformers

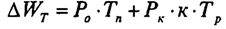

Energy losses in power transformers ΔWt, kWh are equal

where Ro, Pk-no-load and short-circuit losses, kW, are taken according to the passport data (if they are missing according to the directory), k is the load factor of the transformer, Tp, Tr is the number of hours of connection and operation under load, h. In the estimation of losses, the load of the transformer is usually estimated by the monthly energy consumption and reactive power.

For enterprises working in two shifts, Tp is taken 450 hours, in three shifts 700 hours. …

If the transformer was switched off during weekends and holidays, the TP is reduced by the time of the switch off.

Electricity balances of blocks and technological areas

When preparing electrical balances, the consumption of electrical and reactive power is determined using the available control and measuring devices, the use of portable devices, by calculation when there are no control and measuring devices or they are not economically justified.

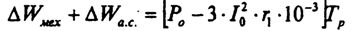

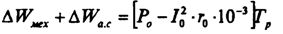

Losses in motors and drives are calculated for large units only. For AC machines

For DC machines

where ΔBeshe, ΔWmech — losses in the steel of the engine and mechanical losses in the unit, kWh, Ro — the idle power of the engine connected to the drive mechanism, determined by the wattmeter (meter), Azo — current at idle, A, ro — armature resistance, Ohm, r1 — resistance of the stator and rotor reduced to the stator for induction motors, Ohm.

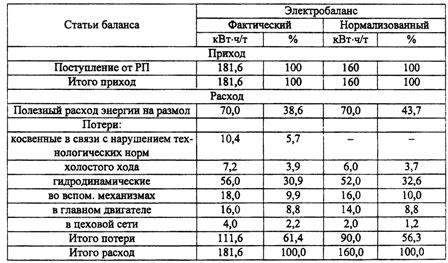

Electric balances are prepared in the form of tables or diagrams expressing balance positions in absolute and relative units.In the normalized electrical balance, there are no indirect losses, since it is assumed that the technological process is in an optimal mode.

An example of an electrical balance:

Electrical balances of workshops and enterprises

The electrical balance in the workshop is obtained by summing the corresponding positions of the electrical balances of the feeders, which in turn are formed by the balances of the technological nodes and nodes. In the consumptive part of the workshop electrical balances, energy consumption in technological processes, main and auxiliary, is distributed in workshop networks, transformers, electric drive, consumption for general needs of the workshop (lighting, heating, ventilation, etc.).

When analyzing the losses in the networks, special attention is paid to the assessment of the mode of consumption of reactive power. Losses in electric drives are usually estimated only for large units, here constant losses are established from no-load power (current) and load losses from average current consumption.

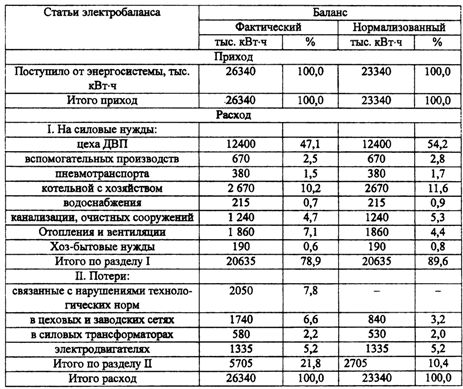

Phaser Factory Electrical Balance:

Electricity consumption can be attributed to a production unit and compared to standards. The electrical balances for the enterprise are prepared by summing up the electrical balances in the shop, taking into account the general needs of the plant, the energy supply of third parties.

See also: Methodology for determining electricity losses in lines, transformers and electric motors, Regulation of electricity consumption in industrial enterprises