Variable electric drive as a means of saving energy

The transition from unregulated electric drive to regulated is one of the main ways to save energy in the electric drive and in the technological field by means of electric drive.

The transition from unregulated electric drive to regulated is one of the main ways to save energy in the electric drive and in the technological field by means of electric drive.

As a rule, the need to control the speed or torque of the electric drives of the production mechanisms is dictated by the requirements of the technological process. For example, the feed rate of the cutter determines the cleanliness of processing a workpiece on a lathe, the reduction of the elevator speed is necessary for accurate positioning of the car before stopping, the need to adjust the torque of the winding shaft is dictated by the conditions for maintaining a constant force of tension of the wounded material, etc.

However, there are a number of mechanisms that do not require a change in speed according to the technological conditions, or other (non-electrical) methods of influencing the parameters of the technological process are used for regulation.

First of all, they include continuous transport mechanisms for moving solid, liquid and gaseous products: conveyors, fans, fans, pump units. For these mechanisms, currently, as a rule, unregulated asynchronous electric drives are used, which set the working bodies in motion at a constant speed, regardless of the load on the mechanisms. Under its partial load, operating modes at constant speed are characterized by increased specific energy consumption compared to the nominal mode.

NSC performance reduction, the efficiency of the conveyor decreases, as the relative share of consumed power overcomes the idle moment. More economical is the variable speed mode, which provides the same performance, but with a constant component of pulling effort.

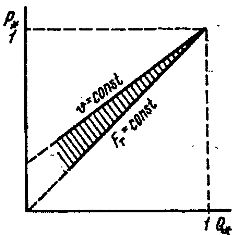

In fig. 1 shows the power dependences of the motor shaft for a conveyor with an idle moment Mx = 0, ЗМв for constant (v — const) and adjustable (Fg = const) speeds of movement of loads. The shaded area in the figure represents the energy savings obtained by speed control.

Rice. 1. Dependence of the power of the electric motor shaft on the performance of the conveyor

So if the conveyor speed is reduced to 60% of the nominal value, then the motors shaft power will decrease by 10% compared to the nominal value. The effect of speed regulation is higher, the greater the idle torque, and the more significantly it reduces the performance of the conveyor.

Reducing the speed of continuous transport mechanisms with underloading allows you to perform the required amount of work with lower specific energy consumption, i.e. to solve a purely economic problem of reducing energy consumption in the technological process of moving products.

Usually, with a reduction in the speed of such mechanisms, an economic effect also appears due to the improvement of the operational characteristics of the technological equipment. So, when the speed decreases, the wear of the conveyor body decreases, the service life of pipelines and fittings increases due to a decrease in the pressure developed by machines for supplying liquids and gases, and the excess consumption of these products is also eliminated.

The effect in the field of technology often turns out to be significantly higher than due to energy savings, which is why it is fundamentally wrong to decide on the advisability of using a controlled electric drive for such mechanisms by evaluating only the energy aspect.

Speed control of shovel machines.

Centrifugal mechanisms for the supply of liquids and gases (fans, pumps, fans, compressors) are the main general industrial mechanisms with the greatest potential throughout the country to significantly reduce specific energy consumption. The special position of centrifugal mechanisms is explained by their massiveness, high power, as a rule, with a long operating mode.

These circumstances determine the significant share of these mechanisms in the country's energy balance.The total installed capacity of drive motors for pumps, fans and compressors is about 20% of the capacity of all power plants, while fans alone consume about 10% of all electricity produced in the country.

The operating properties of the centrifugal mechanisms are presented in the form of dependences of the head H on the flow rate Q and the power P on the flow rate Q. In a stationary mode of operation, the head created by the centrifugal mechanism is balanced by the pressure of the hydro- or aerodynamic network in which it delivers liquid or gas.

The static component of the pressure is determined for pumps — by the geodesic difference between the levels of the user and the pump; for fans — natural attraction; for fans and compressors — from the compressed gas pressure in the network (reservoir).

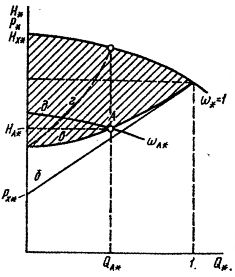

The point of intersection of the Q-H-characteristics of the pump and the network determines the parameters H-Hn and Q — Qn. Regulation of the flow rate Q of a pump operating at a constant speed is usually carried out by a valve at the outlet and leads to a change in the characteristic of the network, as a result of which the flow rate QA * <1 corresponds to the point of intersection with the characteristic of the pump.

Rice. 2. Q-H-characteristics of the pumping unit

By analogy with electrical circuits, regulating flow through a valve is similar to controlling current by increasing the electrical resistance of the circuit. Obviously, this control method is not efficient from an energy point of view, as it is accompanied by unproductive energy losses in the regulating elements (resistor, valve). Valve loss is characterized by the shaded area in Fig. 1.

As in the electrical circuit, it is more economical to regulate the energy source rather than its user. In this case, the load current decreases in the electrical circuits due to a decrease in the source voltage. In hydraulic and aerodynamic networks, a similar effect is obtained by reducing the pressure created by the mechanism, which is realized by reducing the speed of its impeller.

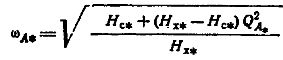

When the speed changes, the operating characteristics of centrifugal mechanisms change in accordance with the laws of similarity, which have the form: Q * = ω *, H * = ω *2, P * = ω *3

The pump impeller speed at which its characteristic will pass through point A:

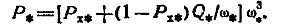

The expression for the power consumed by the pump during speed regulation is:

The quadratic dependence of the moment on the speed is characteristic mainly for fans, since the static component of the head determined by the natural thrust is significantly smaller than Hx. In the technical literature, an approximate dependence of the moment on the speed is sometimes used, which takes into account this property of the centrifugal mechanism:

M* = ω *n

where n = 2 at at Hc = 0 and nHc> 0. Calculations and experiments show that n=2 — 5, and its large values are characteristic of compressors operating in a network with significant back pressure.

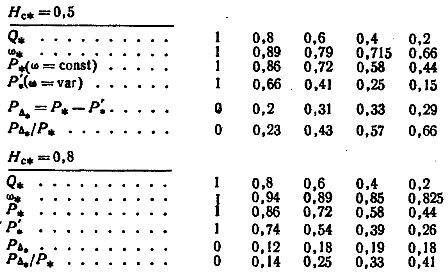

The analysis of the pump operating modes at constant and variable speed shows that the excess energy consumption at ω= const turns out to be very significant. For example, the results of the calculation of the operating modes of the pump with parameters are shown below Hx * = 1.2; Px*= 0.3 on a network with different back pressure Зс:

The given data show that the controlled electric drive can significantly reduce the consumption of consumed electricity: up to 66% in the first case and up to 41% in the second case. In practice, this effect can turn out to be even higher, since for various reasons (absence or malfunction of valves, manual actuation), regulation by valves is not applied at all, which leads not only to an increase in electricity consumption, but also to excessive efforts and costs in the hydraulic network.

The energy issues of single-acting centrifugal mechanisms in a network with constant parameters have been discussed above. In practice, there is parallel operation of centrifugal mechanisms and the network often has variable parameters. For example, the aerodynamic resistance of the mining network changes with a change in the length of the walls, the hydrodynamic resistance of the water supply networks is determined by the mode of water consumption, which changes during the day, etc.

With parallel operation of centrifugal mechanisms, two cases are possible:

1) the speed of all mechanisms is regulated simultaneously and synchronously;

2) the speed of one mechanism or part of the mechanisms is regulated.

If the network parameters are constant, then in the first case all mechanisms can be considered as one equivalent for which all the above relations are valid. In the second case, the pressure of the unregulated part of the mechanisms has the same effect on the regulated part as the back pressure and is very significant, which is why the saving of electricity here does not exceed 10-15% of the nominal power of the machine.

Variable network parameters greatly complicate the analysis of the cooperation of centrifugal mechanisms with the network. In this case, the energy efficiency of a controlled electric drive can be determined in the form of an area whose boundaries correspond to the limit values of the network parameters and the speed of the centrifugal mechanism.

See also on this topic: VLT AQUA Drive frequency converters for pump units