Energy saving with frequency converter

In industry, more than half of all consumed electricity is consumed by electric drives, in particular by powering asynchronous electric motors. See for yourself: ventilation systems, compressors for various purposes, various pumps, variable load installations — all this equipment consumes a significant share of the energy supplied to the enterprise for its power supply.

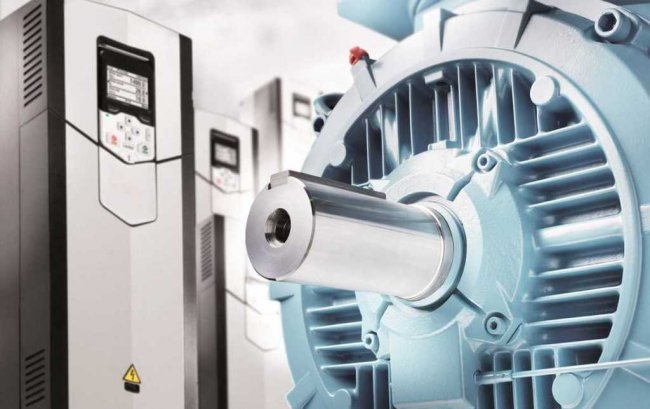

It is not surprising that sooner or later someone will think about the possibility of saving electricity in such installations. And there really is a way out — significant savings will allow you to achieve frequency converter, designed to regulate the engine speed depending on the current operating mode (load) of the equipment. The increase in engine efficiency with such regulation will become very significant, especially when it comes to loads much lower than nominal.

Let's take a closer look at the objective factors affecting the economy here.The water hammer that can occur in the pipes when the pumps are turned on and off without regulation is immediately turned off, that is, the risk of accidents is minimized.

Stop valves will practically not wear out, since pressure regulation in the water supply system will no longer be carried out by valves, but by engine speed, and the valves will always remain open. As the pumps themselves will operate at reduced pressure, pipe breaks and leaks are now less likely to occur.

The amount of repair work on equipment will accordingly decrease, due to the fact that both motors and pipelines will experience less wear, bearings will need to be replaced less often due to wear, as well as impellers, and all this due to smooth speed regulation of the motor and reduction of starting currents.

As a result, more than 60% of resource savings will be given by transferring regulation from throttling, on-off, — to control by changing the engine speed due to the installation of a frequency converter.

Mechanisms such as conveyors, fans, pumps and compressors need a relatively narrow speed control range, and also do not need high accuracy and speed in the adjustment process.

An asynchronous motor with a scalar control system is suitable here, that is, a frequency converter will adjust the voltage level and its frequency accordingly.

If we are talking about a robot, transport or drive of a high-speed metal cutting tool, then in this case a more complex control will be required, a vector control frequency converter will be useful here, which can set high torque at low revolutions, give high acceleration , raise the engine if power is lost for a short time, prevent mechanical resonance frequencies from hitting.

Vector control is most suitable for such systems, where the quality of control and high accuracy of setting the torque of the motor rotor are extremely important.

For cranes, elevators, drilling rigs, extruders, presses, mills, etc. — high-efficiency control of an electric drive by means of a frequency converter will be the key to energy savings in the enterprise and a guarantee of the reliability of the facility.

Frequency converters are also indispensable in residential and communal services, where it is desirable to protect water pipes and heating pipes from water hammer, to protect fittings from premature wear and accidents. And since the pressure can now be maintained not by a shock absorber, but by adjusting the rotation speed of the pump drive, then energy savings will reach almost 50%, not to mention a significant extension of the service life of the stop and control valves.

Articles about frequency converters and their use:

Scalar and vector control of induction motors - what's the difference?

Installation of frequency converters