Calculations of the rate of electricity consumption

Three main approaches are used in the development of energy consumption standards: experimental, computational-analytical and statistical.

Three main approaches are used in the development of energy consumption standards: experimental, computational-analytical and statistical.

An experienced way requires measurements of electricity consumption for each operation in the modes of the technological process specified by the rules. The electricity consumption per unit of production is determined by adding up the operating costs.

This approach requires the use of a large number of measuring devices and significant labor costs. In order to obtain reliable results for each operation, it is necessary to carry out a large number of measurements and statistical processing of the results, as well as to compare the obtained data with the costs of the site, workshop, production. Therefore, this method is mainly applicable to determine individual standards in a specific production environment.

Computational-analytical method involves determining the rate of electricity consumption by calculation — according to the passport data of the technological equipment, taking into account the degree of its load, operating modes and other factors. For general production standards, the power and operating modes of all auxiliary equipment (ventilation, water supply and sewerage, electric lighting, repair needs, etc.) must also be taken into account.

The operating modes of electricity consumers are taken into account using various coefficients (switching on, charging, etc.), the empirical selection and random nature of which lead to significant errors. The element-by-element calculation of the set of energy consumption components makes the method extremely time-consuming.

Statistical method of rationing based on statistical processing of data on general and specific costs for a certain period of time and identification of factors influencing their change. Calculations are made according to the readings of electricity meters and product output data. This method is the least time-consuming, reliable and widely used in the practice of rationing energy consumption. Let's look at the practical methods of its implementation.

The specific consumption of electricity is calculated for a special facility — a production site, a workshop or a separate energy-intensive unit that has its "own" counter at the entrance. The organization of electricity metering is a prerequisite for effective regulation.

A technical system for measuring electricity often does not coincide with the administrative division of the enterprise due to the complexity and branching of the power supply systems. Therefore, when appointing administrative units that carry out rationing, they must be mapped to the accounting nodes.

For the controlled object, the main types of products are distinguished, the production volume of which can be calculated for a shift, a day or for one cycle of equipment operation. Accordingly, the readings of the electricity meters are taken in shifts, daily or for each work cycle.

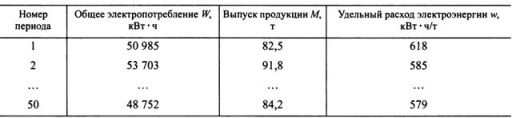

To calculate the characteristic indicators, a preparatory stage for collecting statistical data is necessary - at least 50 periods. Table 1 shows an example view of the initial data representation. At the end of each time interval, the total electricity consumption of the facility (per meter) and production output are recorded. In the last column, the values of specific electricity consumption are entered, obtained by the formula w = W / M, where W is the actual electricity consumption for the production of products in the amount of M (the amount can be measured in different units).

Section. 1.

Actual specific electricity consumption for different periods of time are not the same, which is due to the different load of the selected object, operating modes, composition of raw materials and other factors.If all these conditions are the same, then the values of unit costs are close for different periods, their distribution should be normal (Gaussian). In this case, you can get the average value of electricity consumption for a number of periods and use it as a standard .

It should be noted that the distribution of experimental data is normal (Gaussian) only in the case of the same conditions of the technological process and the same parameters of the manufactured product. Quite often the data does not follow a normal distribution due to two factors.

First, there may be a change in the parameters of products, raw materials or equipment operating modes. For example, the grade of steel and the profile of the rolled metal have a great influence on energy consumption (rolling of the reinforcement determines the specific energy consumption of 180 kWh, stainless steel of the same diameter — 540 kWh). In these cases, monitoring should be organized in such a way as to obtain the required number of measurements from homogeneous products.

Secondly, the violation of the normal distribution is explained by technological properties, which in this case are manifested by deviations from the technology, rejected and missed grades (for example, the volume of the melt is significantly less than the nominal one). It is these cases that the responsible technologist must identify and take action on. The deviation of the distribution from the normal defines a certain area that determines the possible volumes of energy saving through organizational measures.

In order to obtain reasonable norms, it is necessary to check the conformity of the statistical law of the distribution of the specific electricity consumption with the normal (Gaussian) distribution. You can use test by criterion χ2… If the obtained value of the criterion exceeds the theoretical value, the hypothesis of the correspondence of the statistical distribution to the normal should be rejected.

This means that from the obtained data it is impossible to work out a single rate of electricity consumption per unit of production, then they must be divided according to the characteristic technological modes, calculating for each rate of energy consumption, or determine the statistical dependence of the specific consumption by the influencing factors w = f (x1, x2, x3), where production volumes can act as factors x1, x2, x3, temperature, processing speed, etc.

If the check confirms that the distribution of unit costs is close to normal, the rate of electricity consumption can be determined based on this data. For monitoring, it is most convenient to set the range in which the specific energy consumption should be.

The range is most simply determined by the mean flow rate and standard deviation. σ... Simply put, the lower limit of the range can be assumed equal to wmin = wWed — 1.5σ, and the upper one — wmax = wcp + 1.5σ... According to rule 10 — 20% of the specific electricity consumption received in real production conditions, exceeds the specified range, which is due to errors of workers, violations of the regime, deviations in product quality, etc.Technology staff should pay attention to such cases and take measures.

We emphasize that the norms obtained by any of these methods reflect the modes of energy consumption for the production of products only in the enterprise where they are obtained, and cannot be extended either to the industry as a whole or to another enterprise. This is due to the individual properties of each enterprise as a complex system of technological type.

For example, the technological standard for rolling production was experimentally determined depending on metal temperature, rolling speed, calibration, bearing friction, technological losses, etc. cutting speed and machining time. However, these results cannot be transferred to all machine tools, even within a single plant, because in practice there are many types of machined parts and machining modes.

Also, how do you use these velocities obtained for each detail? It is impossible to place an electricity meter near the machine and compare the consumption of each part with the standard. Generalizing the standards, taking into account the number and range of parts produced, will lead to a large error due to the inability to take into account all the factors at work.

Also, using the computational and analytical method, it is impossible to go from data on the nominal power of individual electrical receivers, taking into account all possible technological modes, types of products, quality of raw materials, to electricity consumption for a workshop or enterprise for a month , quarter, year.

It is impossible to obtain the estimated value of energy consumption by the enterprise by summing up different specific norms for the entire range of products. To do this, it is necessary to plan in advance not only the total amount of products that will be released in the next month (quarter, year), but also to accurately divide it by brands, characteristics of processing modes and many other factors. This was impossible in the conditions of a planned economy and even more so now.

It is impossible to compare different enterprises and according to the extended standards for the whole plant even with close technological cycles. Thus, in 1985, in ferrous metallurgy enterprises, the specific electricity consumption of 1 ton of rolled products took values from 36.5 to 2222.0 kW • h / t with an industry average of 115.5 kW * h / t; for converter steel — from 13.7 to 54.0 kW • h / t with an industry average of 32.3 kW • h / t.

Such a significant spread is explained by the difference in technological, organizational and social factors for each production, and it is clear that the average industry norm cannot be extended to all enterprises. At the same time, the enterprise cannot be considered inefficient if it exceeds the industry average.

Reduced production, incomplete and erratic utilization of equipment lead to higher unit costs, further widening the data gap. Therefore, in today's conditions, industry average levels of electricity consumption can neither be used to predict energy consumption nor to estimate energy savings.