What is electrolytic earthing

Electrolytic grounding or grounding with an active chemical electrode, in one way or another, has an idea for those who at least once independently made grounding in the country, for example, for a detector radio. To improve the quality of the ground by reducing its resistance, you had to water the place of installation of the loop or pin with salt water.

Today, electrolytic grounding is produced in the form of special equipment that can be purchased and installed. Its installation is quite simple, because the solution matured in the minds of engineers for some time before the structure took the form of a modern high-tech solution.

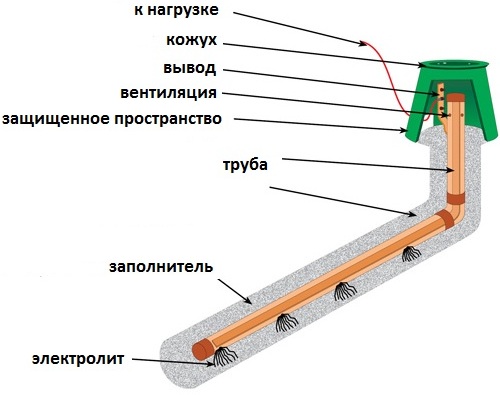

The direct grounding electrode here is made in the form of a copper or steel tube, usually 50 to 70 mm in diameter. As you know, neither stainless steel nor copper while in the ground do not corrode, therefore grounding pipes are made of these metals.

The salts are located inside the electrode tube, in the walls of which holes are made, through which the salts are gradually washed out, mixed with the soil moisture and thus become an electrolyte — the leaching process takes place. As a result, the electrolyte formed near the electrode lowers the freezing point of the soil while increasing its electrical conductivity.

The original purpose of electrolytic earthing is to improve the quality of earthing as such, especially in soils with high resistance, such as rocky soil or permafrost, where it is desirable to somehow organize earthing without unnecessary problems and without loose soil.

Soil resistance of this type, as a rule, exceeds 300 Ohm-m, and often in these places it is simply impossible to deepen the electrodes by more than 1 meter, and if pins are installed, then dozens of them will be needed under such conditions of high soil resistance

During the installation of electrolytic grounding, the soil around the electrode is replaced with a special filler-activator, which is characterized by low own resistance… The result of such an operation is to reduce the resistance of the transition from the grounding electrode to the ground and to increase the contact area between the ground and the ground in order to maximize electrical conductivity.

This grounding configuration, even with a ground electrode length of about 5 meters, already allows you to reduce the total number of electrodes to a minimum, while maintaining an acceptable resistance.As a result, not only the cost of installation is reduced, but also the transportation of the required number of grounding kits for your electrical equipment.

Even if the climatic conditions (season or just the weather) suddenly change drastically, electrolytic grounding will remain stable, because its very design, the very device of this type of grounding, will only contribute to the improvement of the quality of grounding over time.

So, the use of electrolytic grounding with an activator around the electrode gives its owner the following advantages:

- The installation depth of the electrode is less than 1 meter.

- Electrodes do not corrode quickly over time and are not pushed out of the soil.

- Salts turn into electrolyte gradually, leaching is slow.

- Ground resistance decreases over time.

- The life of the electrode is tens of years.