The main malfunctions of electromagnetic switching devices and methods of their elimination

Faults of electromagnetic switching devices can be grouped according to the following criteria: the place of their occurrence in the design, the type and nature of their occurrence, the degree of performance loss.

Faults of electromagnetic switching devices can be grouped according to the following criteria: the place of their occurrence in the design, the type and nature of their occurrence, the degree of performance loss.

Types of wear of electrical contacts

The contacts of the switching elements are subject to electrical and mechanical wear during operation.

Electrical contact wear occurs both when closing and opening circuits and is affected by many factors, the main ones being:

-

type of current (direct or alternating current);

-

current and voltage values;

-

the nature of the load (active, inductive);

-

response rate;

-

the environment in which the contacts work;

-

duration of arc burning on the contacts;

-

the duration of the contacts' vibrations and their first amplitude when switched on; the contact material, its micro- and macrostructure; geometric shape and size of contacts;

-

contact gap percentage at turn-off.

The mechanical wear of the contacts depends on the material of the contacts and its physico-mechanical properties, contact actuation conditions (values of impact loads, presence of sliding, etc.

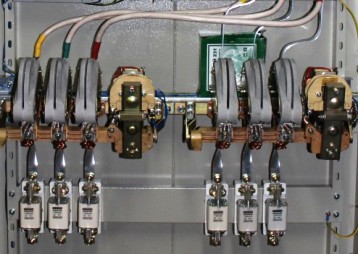

Supervision and maintenance of electromagnetic switching devices (contactors, starters and relays)

Contactors, starters and relays should be checked at least once every 2-3 months, cleaned and troubleshooting. The frequency of checks is adjusted depending on the operating conditions. Keep insulating surfaces clean. To do this, wipe the contactors, starters and relays with a dry cloth.

Contact links it should be clean and tight. The joints are cleaned with a steel brush, wiped with a napkin moistened with gasoline, lubricated with technical petroleum jelly and the screws are tightened tightly.

The degree of pressure of the contacts must correspond to the factory instructions. Light pressure causes increased heating, increases contact wear, excessive pressure increases vibration and hum.

Contact wear should not exceed 70% of the original thickness. In case of uneven wear, the contacts are replaced.

The mechanical blocking of the return contacts of the electromagnetic starter must be periodically checked. Mechanical interlock is checked at least after 1 million power-ups, corrected according to factory instructions.

Repair of electromagnetic switching devices

Contact repair

The shape of the contacts is taken according to the factory drawings. Worn silver contacts are replaced with new, spare ones.

The final pressure is measured with an electrical apparatus with a dynamometer on and a strip of paper placed between the movable and stationary contacts. The value of the final pressing will be marked with a dynamometer at the moment when the piece of paper begins to be freely withdrawn from the closed contacts.

Initial compression is measured in the same way, but with the contactor, starter or relay traction coil disconnected. The initial pressure is created by the apparatus spring at the point of initial contact of the contacts.

The contact pressure is adjusted by pressing or loosening the contact spring. The spring should not be brought to a position where there are no gaps between its turns. If the adjustment fails to achieve the desired pressure, then the spring should be replaced.

Contact gaps and dips must be in accordance with factory specifications. The solution between the contacts provides arc extinguishing, and immersion is necessary for the reliable closing of the contacts of the electrical apparatus.

Anchor and core

The fit between the armature and the core must be tight enough to avoid rattling and overheating of the coil. If the joint is in an unsatisfactory condition, the contact surfaces are stamped. The connection between the armature and the core of the contactor or starter is checked by manually closing the contacts with a sheet of tissue paper with a sheet of copy paper placed between them.The fit is considered satisfactory if the impression obtained is at least 70% of the cross-sectional area of the rod.

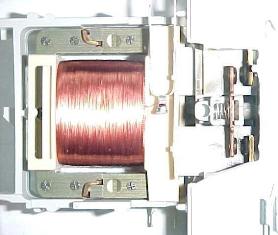

Coils

In determining the nature of the damages coils contactors, starters and relays, you need to pay attention to the state of the frame, breaks and short-circuit rotation in the coils. In the event of a coil break, the coil does not develop traction and does not consume current. Coil faults are characterized by abnormal heating of the coil and a reduction in its tensile strength.

An outer insulation of cotton tape or varnished cloth is applied to the produced coil. The coil is then dried, soaked in varnish, baked and covered with enamel.

Before installing the coil in the device, check its integrity and the absence of a short circuit in it.

In case of short-circuit damage, the damaged turn is replaced with a new one. Changing the materials, cross-section or length of the coil is unacceptable, as this leads to increased buzzing of the contactor and strong heating of the coil.

Arc chutes

Burnt and deformed walls rainbow chutes replaced with new ones.

Causes of failure of contactors, starters and relays

Damage to individual functional units of devices is a consequence of various irreversible processes. These processes are caused by the joint action of a large number of random factors, which is why failures most often have a random nature.

The main causes of "open" and "rotating circuit" type failures in the coils of contactors, starters and relays are usually considered to be mechanical influences, thermal and electrical loads leading to terminal breakage and winding damage, transient electrical processes during shutdown and inclusion of the supply voltage of the windings, which leads to overvoltages and destruction of the insulation, continuous current flow exceeding the specified value, damage to the insulation due to electrolysis phenomena, occurrence of a short circuit in the winding.

Typical causes of sudden failures of mechanical elements of electromagnetic switching devices are irreversible deformations and breakage of individual parts, for example, short circuits, plastic elements of the housing and crossbars, loosening of fasteners, distortions, jamming and jamming of the movable executive system of the device.

Sudden failures of the contacts of switching electromagnetic devices can be divided into failures such as "contact does not close", "contact does not open" and "failures".

Gradual contact failures are caused by wear and aging of individual functional units and parts of contactors, starters and electromagnetic relays.

The type of contact failure is determined by the value and nature of the load. In DC circuits with loads exceeding fractions of an ampere, "contact does not close" failures predominate. In circuits with high currents, where bridging and arcing phenomena are common, "contact does not open" type failures predominate.