Operation of buses and trolleys

Modern buses and trolleys are quite reliable and in the process of operation need only periodic cleaning from dust, dirt and control of the condition of contact connections and insulation.

Modern buses and trolleys are quite reliable and in the process of operation need only periodic cleaning from dust, dirt and control of the condition of contact connections and insulation.

Dust and dirt can lead to a reduction in the insulation level of the busbar and, as a result, an emergency failure. They are removed with a vacuum cleaner or by blowing air with the hoods open. Poor contact condition leads to overheating.

The level of heating of the contact connections of the busbars for 1000 A and more is determined using thermal indicators. Bolted connections should be checked periodically to ensure that they are not over-tightened, which can cause the aluminum to warp and therefore deteriorate the contact.

During operation, special attention must be paid to the detachable contacts of the junction boxes of the plug connections. If necessary, clean them with a thin flat file or medium-grit sandpaper. The isolation state is determined using a megohmmeter… It is allowed to use the "burn-in" method to detect certain types of damage to the insulation of the buses and trolleys.

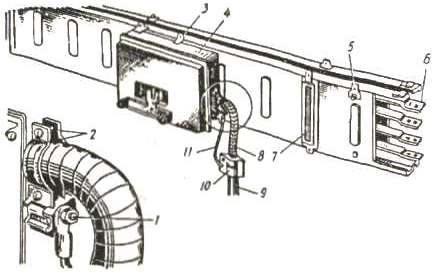

If a serious malfunction is detected, the defective section of the bus must be dismantled and repaired in a workshop or replaced with a new one. Without disassembly, it is allowed to carry out only some types of minor repair work on rails and trolleys, in particular, replacing a defective junction box with them (Fig. 1).

Rice. 1. Bus junction box replacement: 1 — ground bolt, 2 — special clamps, 3 — clamp, 4 — junction box, 5,10 — connectors, 6 — conductive busbars, 7 — plug, 8 — flexible metal hose, 9 — pipe, 11 — grounding

Safety rules and regulations when working with rails and trolleys

The installation of workshop rails and trolleys can be carried out using an auto-hydraulic lift, a mobile platform ladder (attached to the crane track), an overhead platform (attached to the crane bridge) and a crane.

During the operation of the platform ladder, it is necessary to attach the safety belt with carabiner to the safety rope. The suspension platform installed on the workshop mounting crane must be reliable, have handrails, side rails and a hanging net to catch accidentally falling objects. At the same time, the crane for the installation of service bus channels and trolleys is allowed to be used only on those sections of the crane tracks where the installation has been completed and the written permission of the mechanical installation organization has been obtained.

The area where the crane is allowed to move should be fenced off with brakes to prevent the crane from accidentally moving to another area.

During installation, joint work with an electric welder must be carried out in a protective helmet, and with gas welding - in protective colored glasses. During operation, without removing the tension of the wires and trolleys of the bus, it is allowed to connect and disconnect additional electrical receivers with plug-in (detachable) contacts, cleaning with a vacuum cleaner or blowing air, as well as work on grounded sheaths ( painting, labeling, reinforcing plates).

The rest of the work is done with complete stress relief. The bus must be disconnected from all sides from where voltage can be applied to it. In this case, the disconnection is carried out with a visible gap, for which it is necessary to remove the fuses or disconnect the power cables.