Types and causes of wear and tear of electrical equipment

All objects created by man or with his participation are subject to wear and tear from the first moments of finishing work on them. This happens during operation, storage or even canning. This also applies to electrical equipment. As a result, it needs repair and restoration work from time to time. According to the type of wear of electrical equipment, it can be mechanical, moral and electrical.

All objects created by man or with his participation are subject to wear and tear from the first moments of finishing work on them. This happens during operation, storage or even canning. This also applies to electrical equipment. As a result, it needs repair and restoration work from time to time. According to the type of wear of electrical equipment, it can be mechanical, moral and electrical.

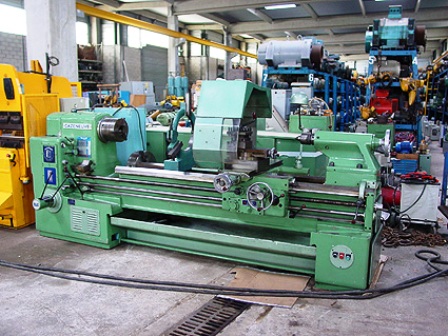

Mechanical wear and tear of electrical equipment

If we talk about mechanical wear of electrical equipment, it means a change in the initial forms of the whole device, its constituent parts or individual parts that arise in the process of permanent or temporary, both external and internal influences.

Mechanical wear can manifest itself as cutting, scratching, thinning of coatings or technological layers. Most often this happens at the points of contact between parts moving relative to each other.So, during operation, mechanical wear occurs on the collector of electric machines. Traces appear on it, working due to the fact that the metal is erased in the friction process, turning into metal dust, which is blown out of the case with an air stream or settles on the inner surface of the case.

Rapid wear of the electrical collector can be facilitated by pressing the brushes harder than necessary or by using a brush harder than specified by the manufacturer. Each pair of parts in contact with each other is calculated separately for stiffness. And the one that is structurally designed not for repair, but for regular replacement, like a carbon brush, should be softer than the one with which it comes into contact - the collector. Then wear will be minimal.

In the case of electrical devices, mechanical wear is also possible. It is expressed in the fact that during operation, heating, the initial geometry of the contacts changes, the clamping or return springs of the mechanisms weaken and deform.

As for drive electric motors, their main wear occurs at the points of contact of moving parts with stationary ones. This is a journal on the shaft, rings on the rotor, all kinds of bearings. Also, mechanical wear threatens external protective coatings if they are regularly exposed to destructive mechanical stress.

In most cases, mechanical wear requires regular prevention, repair of electrical equipment, replacement of worn parts and assemblies. In some cases, it is possible to partially restore their operational properties and reuse them.

Electrical wear of electrical equipment

For electrical equipment, there is also such a type of wear and tear as electrical. In this case, the geometry of the products, their mass may remain the same, but there is an irreparable loss of the electrical insulating properties of the individual elements of the electrical equipment. So, in an electric machine, the insulation in the channels can wear out.

Otherwise, the windings of the transformer will wear out. Such wear is sometimes invisible to the eye and can only be detected with tools. Sometimes electrical wear is a consequence of exposure as a result of long-term use under normal conditions. Most often, however, the action of an aggressive environment, high temperature and other unfavorable factors accelerate the equipment's failure or its partial failures.

Under the influence of an unacceptable temperature according to technical standards or when the concentration of aggressive chemicals is exceeded, the insulating layers are destroyed. As a result, they are gradually or simultaneously destroyed, lose, change their electrical insulating properties. Then there is a short circuit between the turns of the windings, insulation failures occur, there is a potential output to those parts of the equipment that should not be powered.

Such electrical wear and tear can not only endanger the operation of electrical equipment, but also lead to breakdowns, fires, accidents, injuries and deaths of people who have access to it.

Timely detection of electrical wear, high-quality removal of its consequences, one of the main conditions for safety.This usually happens during the overhaul of electrical equipment, since it is not always possible to identify a certain place of wear, as in the case of insulation damage in the individual turns of the windings, to penetrate to it without destroying them other layers.

Electrical wear is also possible as a result of deposition of coal dust, metal, moisture penetration and, as a result, the appearance of rust at the contact points.

Aging

You can also talk about the obsolescence of electrical equipment. This is a specific type of wear and tear. It takes place even when the actual fact of exploitation is absent. Equipment is stored or operating properly and safely. Its further use or installation becomes impractical due to the fact that more advanced analogues have already been created and implemented. They are more technologically advanced and more economical.

This process happens everywhere. It applies to all types of materials and technologies, light industry products, consumer goods. Progress is constantly creating a more attractive, safer and easier to use product. Scientific discoveries enable equipment to possess properties and functions that were previously unavailable to it.

But at the same time, the obsolescence of electrical equipment is not the last sentence for sending it to scrap. Most often, innovations refer to some elements, nodes, management systems. The basic principle of operation, say, of the windings of the transformer or its case, remains the same and allows to work successfully in the future.

Modernization can improve the quality of further operation of outdated or, as they say, obsolete equipment. And the deeper it is, the more the parameters of the outdated equipment approach the parameters of newer and more technically advanced ones. Retrofitting helps extend the life of obsolete industries by integrating them into the ever-changing technical world while saving significant costs.

Removal of all types of wear

To eliminate all types of wear and tear on electrical equipment, the most preferred system is scheduled preventive repairs and inspections. Its essence lies in the fact that, without waiting for damage or breakdown of the equipment, regularly, according to the schedule, preventive work, regular repairs, replacement of the most vulnerable units and parts in terms of wear are carried out.

The overhaul period is determined taking into account the mode and conditions of operation, the age of the equipment, its deterioration, condition. But these are not the only conditions that determine frequency. Its selection also takes into account the factors of the presence of redundant systems, the continuity and safety that the enterprise where the electrical equipment is used must have, as well as the presence or absence of its own maintenance teams. The administration does not always have the opportunity to keep such specialists in the staff in the necessary volume.

Recently, it has become popular to conclude contracts for this type of preventive maintenance of electrical equipment with companies that deal with its installation, commissioning. Widely used monitoring and diagnostic systems, they allow early identification of possible premature wear sites. This approach has made it possible in recent years to significantly reduce the cases of emergency breakdowns of electric motors, to increase the reliability and continuous operation of generating plants, transformer substations.