What factors affect the aging of insulation

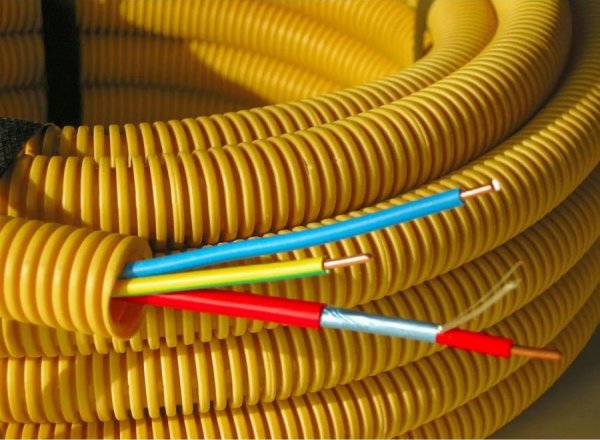

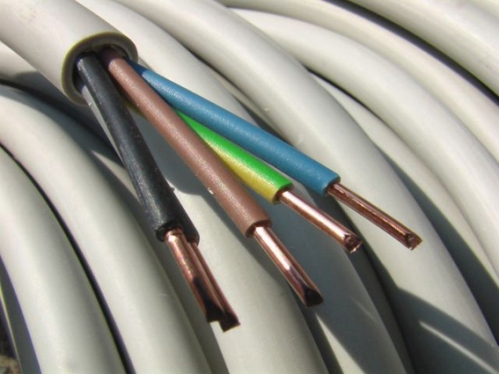

Long-used cables lose their insulation quality over time, in other words, their insulation ages. This is due to a number of factors. As a result, some places of the wiring are exposed, which is fraught with dangerous accidents: accidental short circuits and sparks can lead to fire or at least electrical injuries to people.

Of course, the insulation materials used today are more durable than those used earlier, but in some places electrical wiring has not changed for a long time and the problem of aging insulation remains. Let's look at the factors that affect the aging of insulation.

Insulation aging is measured in relative units. Aging is taken as a unit corresponding to operation at the temperature allowed by the standards. For practical calculations, a rule known as the «rule of eight degrees» is often used to estimate the aging process of insulation.

This rule, although only a special case of the general law of aging, gives a good approximation to reality in the temperature range normally allowed for insulation. At higher temperatures this results in slightly exaggerated aging data, but remains useful for relative estimates.

The meaning of the eight-step rule boils down to the fact that an increase in temperature for every 8 ° C leads to accelerated wear (aging) of the insulation twice. This means that if, for example, the cores of wires with insulation during overload will have a temperature rise of 48 ° C instead of 40 ° C accepted in the norms, then their insulation will wear out 2 times faster and at a temperature of 56 ° C — 4 times faster.

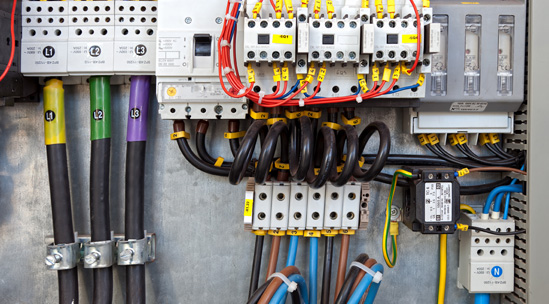

The main factors for the aging of the insulation are the following. Operating voltage or rare overvoltage can sometimes cause partial discharges in the insulation, resulting in so-called. Electrical aging of insulation.

The main factors for the aging of the insulation are the following. Operating voltage or rare overvoltage can sometimes cause partial discharges in the insulation, resulting in so-called. Electrical aging of insulation.

This is followed by aging due to exposure to heat and oxidation. Finally, moisture insulation is also a pretty strong aging factor that shouldn't be overlooked.

Additional (less significant) aging factors are: mechanical loads of a static or vibrational nature and chemically destructive effect of products of electrolytic reactions and organic acids.

Electrical aging of insulation — gradual accumulation of microcracks from discharges

Partial discharges lead to the gradual destruction of most types of insulation: with each discharge, only part of its energy is spent on irreversible destruction of the molecular bonds of the material, as a result of which the destruction occurs slowly but surely.It looks like microcracks in the insulation.

The degree of destruction and its scale are different for different materials. Organic dielectrics, under the action of partial discharges, release conductive carbon compounds, as well as gases: hydrogen, methane, carbon dioxide, acetylene, etc. When the molecular bonds of solid dielectrics are broken, radicals are formed.

Oil-barrier and paper-oil insulation changes the electrical characteristics and physico-chemical properties in each of its components: electrical cardboard, mineral oil and paper-aging, the impregnating composition is destroyed, the conductivity ultimately increases, favorable conditions for harmful destruction are created .

As for the oil itself, under strong electric fields the electrons in it acquire enough energy to destroy the carbon molecules, as a result of which hydrogen is released. This process is particularly pronounced in the insulation of high-voltage lines, and different types of insulation are characterized by their own intensity of destruction (which depends on the composition of the insulation).

It is worth noting here that the breakdown of the insulation with the formation of a crack does not occur immediately due to overvoltage at any moment. This process is slow: microcracks accumulate each time a new surge occurs, and only at the end does it look like insulation damaged by cracks.

Thermal aging — chemical reactions that deteriorate the properties of insulation

It is clear that under normal conditions at 25 ° C all insulating materials behave normally, they are inert at room temperature.However, the current flowing through the cables heats the insulation up to 130 ° C and even higher. Under such circumstances, chemical reactions slowly occur in the insulating material, gradually deteriorating its properties.

Dielectrics are initially rigid — they become brittle over time, and any significant mechanical stress on the cable will cause cracks and destruction of such insulation. Liquid dielectrics gradually evaporate, partially turning into a gas, due to which the dielectric strength of such insulation decreases over time. It is also a network of aging insulation from the action of heat.

Moisture as an aging factor—oxidation that promotes leakage

It is not surprising that moisture can get on the insulation of the cable, whether it is condensation formed as a result of thermo-oxidative processes or simply water from the external environment, the same seasonal precipitation.

Insulation resistance is reduced by the action of moisture as the free ions begin to increase the leakage current. Dielectric losses increase, eventually leading to total breakdown. But even if no damage occurs, moisture still contributes to overheating of the insulation and thermal aging is not delayed.

That is why it is so important that the insulation always remains dry, and in large industries, in connection with this provision, the moisture content of the insulation is constantly monitored and measures are taken to reduce this aging factor to a minimum.

See also:

Insulation quality indicators — resistance, absorption coefficient, polarization index and others

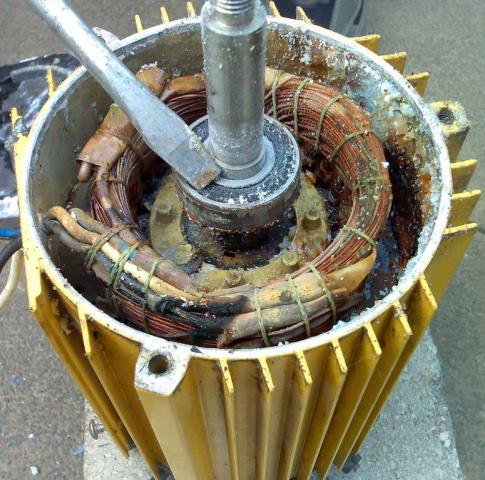

What determines the service life of electric motors

Causes of fires in electrical devices

Heat resistance and fire resistance of cables and wires, non-combustible insulation

How is the cable insulation test performed correctly?