Support of operating current sources and network

When working with electrical equipment at power plants and substations, it is very important to maintain sources of working current, especially rechargeable batteries. The reliability of their work largely depends on the condition of the premises where the batteries are placed and on the systematic and strict application of all the rules for their work.

When working with electrical equipment at power plants and substations, it is very important to maintain sources of working current, especially rechargeable batteries. The reliability of their work largely depends on the condition of the premises where the batteries are placed and on the systematic and strict application of all the rules for their work.

In storage rooms (in storage batteries), the temperature must be maintained at least + 10 ° C, and in substations without constant load at least + 5 ° C, the operation of supply and exhaust ventilation and cleanliness must be monitored.

In order to prevent an explosion (during operation of the battery, a significant release of hydrogen is possible), smoking and starting a fire, using blow torches and welding in the battery room are not allowed. Heating devices must not have flanged connections. The ventilation must be on while the battery is being charged.

The battery room should always contain 5% soda solution in case of acid burn and 10% boric acid solution when working with alkali.

To avoid saturating the air in the battery compartments with sulfuric acid fumes, the jars are covered with glass plates. The sulfuric acid vapor is concentrated on the lower surface of the plates and flows back into the vessel.

Frosted glasses are used to protect batteries from direct sunlight. Walls, ceilings and all metal parts are painted with acid-resistant paint. The unpainted parts of the wires are lubricated with petroleum jelly. Batteries should be equipped with protective clothing (rubber boots and gloves, rubber aprons, acid-resistant woolen or cotton suits), goggles, a battery lamp or a sealed flashlight.

In the charging process, lagging elements and short circuits in the plates are revealed - due to their weak gas release and the low density of the electrolyte, which as the charge progresses should increase uniformly in each element to 1.21 g / cm3. The end of charging is characterized by a number of signs: the voltage and density of the electrolyte of each cell reach the highest values (respectively 2.5-2.75 V and 1.2-1.21 g / cm3) and remain stable for 1 hour, intense gas formation (boiling of battery)) starts immediately after switching on the charging current.

When charging, the temperature of the electrolyte should not exceed 40 ° C. Batteries with charging capacity should always be in a charged state. The voltage in the cells under normal conditions is maintained at 2.15 ± 0.05 V. In deep discharges, the voltage in the cells should be at least 1.9-1.85 V.

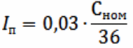

The float current should be:

where Sleep is the nominal (10-hour mode) electrical charge of the battery, Ah.

On all batteries, distilled water is poured only into the bottom of the vessel using a glass or plastic tube with a funnel. The length of the tube is chosen so that when the funnel rests on the edge of the vessel, the tube does not reach the bottom of the vessel by 5-7 cm. Care must be taken that water does not fall on the electrolyte. When making up the electrolyte, sulfuric acid should be poured into distilled water in a thin stream (and not the other way around), constantly stirring the solution.

At least once a quarter, the voltage of the cells and the density of the electrolyte in the upper and lower layers of the vessels are measured. The difference in density should be no more than 0.02 g / cm3.

Recommended at least once every 3 months. check the condition of the battery by measuring the voltage at the battery terminals when it discharges with the maximum allowable current for 1-2 s, for example, when you turn on the switch closest to the battery with the most powerful electromagnet. In this case, the battery voltage should not decrease by more than 0.4 V from the voltage at the moment preceding the current jump.

For the timely detection of malfunctions, batteries are checked systematically: daily by the battery operator (at large substations) or by the electrician on duty (at substations where there is staff on duty), 2 times a month by the captain of the electrical department or the head of the substation, according to the schedule at equipment inspections by the operational field team at substations without permanent staff.

During inspections, they check:

• the integrity of the dishes and the level of electrolyte in them, the correct position of the cover glasses, the absence of leaks, the cleanliness of the dishes, racks, walls and floors,

• the absence of lagging elements (usually the lagging element has a low density of the electrolyte and poor gas release), the reason for the lagging is most often a short circuit between the plates, which can occur due to the formation of sediment, loss of active mass, distortion of the plates ,

• electrolyte level (the plates in the cells must always be covered with electrolyte, the level of which is maintained 10-15 mm above the upper edge of the plates), when the level drops, distilled water is added if the density of the electrolyte is higher than 1.2 g / cm3 or sulfuric acid solution with a density of 1.18 g / cm3, if it is less than 1.2 g / cm3,

• lack of sulfation (white color), distortion and short circuit of the plates - at least once every 2-3 months, the signs of a short circuit are low voltage and the density of the electrolyte in the cell compared to others (with a metal short circuit, the plates heat up, the temperature of the electrolyte also rises),

• lack of contact corrosion,

• the level and nature of the sediment (in glassware), the distance between the bottom edge of the plate and the sediment must be at least 10 mm, and the sediment must be removed promptly to avoid short-circuiting of plates,

• serviceability of the element switch (if any), check whether there is a short circuit between adjacent contacts, the integrity of the resistance built into the slide,

• serviceability of charging and recharging devices,

• functionality of ventilation and heating (in winter),

• electrolyte temperature (via control elements).

Periodically, at least once a month, check the voltage and electrolyte density of each cell. The condition of the insulation is systematically monitored during inspections.

The presence of impurities in the electrolyte can lead to the destruction of the plates, and the service life and capacity of the battery are directly dependent on the quality of the electrolyte. The most harmful impurities are iron, chlorine, ammonia, manganese. To prevent the ingress of impurities, sulfuric acid and distilled water are checked in a chemical laboratory. At least once a year, the electrolyte of 1/3 of all elements of a working battery is analyzed.

Battery capacity is checked once every 1-2 years. To do this, the charged battery is discharged to a previously distributed load to a voltage of 1.7-1.8 V, and the capacity is determined depending on the current and discharge time.

When checking — at least once a month — use the following devices: when measuring insulation resistance — with a voltmeter with an internal resistance of at least 50 kOhm, when measuring the voltage of individual batteries — with a portable voltmeter with a 0-3 V scale, when measuring density and the temperature of the electrolyte — a hydrometer (hydrometer) with a measurement range of 1.1 — 1.4 g / cm3 and a graduation of 0.005 and a thermometer with a range of 0-50 ° C.

Routine repairs of storage batteries are carried out if necessary once a year, capital repairs - no earlier than 12-15 years.In a number of power systems (Mosenergo, etc.), average repairs are carried out once every 2 years, during which the identified deficiencies and violations are eliminated: replacement of plates and separators, seals between insulators and vessels, condition of rations and contacts is checked, lubricated , and the outer surfaces of boxes and racks, wiping live parts and insulators, etc.

• regulation of voltage and current in accordance with the charging and discharging mode of the batteries,

• control of the operation of the device according to the installed devices and signaling equipment,

• replacement of blown fuses and lamps,

• removing dust from the external surfaces of the device,

• control over the operation of relay contacts, contactors, etc.

Work with rectified current sources (rectifiers, power supplies, stabilizers) consists of an external inspection, cleaning the housing and equipment from dust, identifying defects, monitoring the load on devices, monitoring heating and cooling of devices. In addition, the load on ferroresonant stabilizers (C-0.9 and similar) should be monitored, since at low load these devices do not provide a stable output voltage.

Given that the rectifier units are not autonomous sources of operating current and their operation is possible only if there is voltage in the alternating current circuits, special attention during their operation is paid to the operational capabilities of ATS units, circuit breakers, contactors, relays and other equipment that ensures the reliability of AC power rectifiers.

The main task of running capacitor sources is to ensure that they are always in a charged state and ready to ensure the operation of cut-off electromagnets, relays and other devices. To do this, it is necessary to maintain the insulation of capacitors, power circuits and other items in proper condition.

AC power loss is particularly dangerous for capacitor sources, as they discharge rapidly in this case. In 1.5 minutes, the charge of the capacitors is so reduced that they are no longer able to provide power to the operating circuits for tripping switches, etc. Capacitors from the charger, but also discharge them by shunting with a resistance of 500-1000 ohms.

Testing of capacitor sources of operating current is carried out approximately once a year, measuring the level of charging voltage of capacitors with a high resistance voltmeter, in addition, the serviceability of diodes is checked. The chargers are designed to charge capacitors up to 400 V.

Transformers used as AC sources are serviced, as are power and instrument transformers.

Maintenance of ATS equipment, switchboards and assemblies of breakers, contactors, fuses is carried out in the same way as the operation of low-voltage electrical equipment. It should be borne in mind that malfunctions in the control circuits can have serious consequences. Therefore, special attention should be paid to the presence of operating current, providing isolation control and selectivity of protective devices in rectifier current circuits.

The insulation resistance in the operating current circuits, usually measured with a 1000 V megohmmeter, should be maintained at a level of at least 1 megohm.