Three-section conveyor drive chain

In the presence of complex cargo flows consisting of production machines and mechanisms connected by conveyors, all machines and conveyors are divided into sections. The part of the flow-transport system that provides a certain stage of technological operations is called a section. The site, in turn, is divided into paths. In this case, all mechanisms of the technological process can be managed from the dispatcher console. As an example, consider the drive control circuit of a three-section conveyor.

In the presence of complex cargo flows consisting of production machines and mechanisms connected by conveyors, all machines and conveyors are divided into sections. The part of the flow-transport system that provides a certain stage of technological operations is called a section. The site, in turn, is divided into paths. In this case, all mechanisms of the technological process can be managed from the dispatcher console. As an example, consider the drive control circuit of a three-section conveyor.

In a three-section conveyor, each section is usually driven by a separate motor, the operation of the motors must be coordinated. So, in the case of inconsistent operation of the three-section conveyor, stopping the first section while continuing the operation of the second and third will cause the stopped section to be blocked from the delivered material.To avoid this, the control circuit of the conveyor motors must be designed in such a way that the stoppage of any of the motors results in the automatic stoppage of all previous sections, counting from the feed of the material.

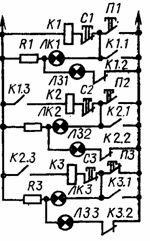

Rice. 1 Control circuit of the electric drive of a three-section conveyor

The necessary functional connection between the motors is achieved by input into the control circuit magnetic starters each motor on the contacts of the magnetic motor starter closing block of the next section. In this case, each engine (except the first) can be turned on only after the next engine on the section has been turned on. So the magnetic starter K2 of the electric motor M2 can be turned on only when the contacts K1.3 of the magnetic starter K1 of the motor M1 are closed.

When one of the motors is stopped, the motors of the previous sections are stopped, for example, when: motor M2 is turned off, contactor K2 opens its auxiliary contacts, including K2.3 in the circuit of contactor K3, which causes the latter to turn off and to stop the M3 engine. If the magnetic starters are disabled, then the break contacts K1.2, K2.2 and K3.2 close and the green lamps LZ1, LZ2, LZ3 will light up.

When one of the starters is actuated, it will open its closing contact and the corresponding lamp will go out, at the same time the contact of the closing block K1.1, K2.1 or K3.1 will close, blocking the P1, P2 or PZ start button , as a result of which the red lamps LK1, LK2 or LK3 will light up, indicating which of the starters is currently working. The magnetic starter K1 of the motor M1 can be switched on regardless of the operation of other motors.