What is ultrasound and how is it used in industry?

Ultrasound is called elastic waves (waves propagating in liquid, solid and gaseous media due to the action of elastic forces), the frequency of which lies outside the range audible to humans — from about 20 kHz and more.

Initially, ultrasonic and audible sounds were distinguished only on the basis of perception or non-perception by the human ear. The hearing threshold of different people varies from 7 to 25 kHz, and it has been established that a person perceives ultrasound with a frequency of 30 - 40 kHz through the mechanism of bone conduction. Therefore, the lower limit of the ultrasound frequency is conventionally accepted.

The upper limit of the ultrasound frequency extends to frequencies 1013 — 1014 Hz, i.e. up to frequencies where the wavelength becomes comparable to the intermolecular distances in solids and liquids. In gases, this boundary is located below and is determined by the free path of the molecule.

Useful functions of ultrasonic waves

And although physically ultrasound has the same nature as audible sound, differing only conditionally (higher frequency), it is precisely because of the higher frequency that ultrasound is applicable in a number of useful directions.

So, when measuring the speed of ultrasound in a solid, liquid or gaseous substance, very minor errors are obtained when observing fast processes, when determining the specific heat (gas), when measuring the elastic constants of solids.

High frequency at low amplitudes makes it possible to achieve increased densities of energy flows, since the energy of an elastic wave is proportional to the square of its frequency. In addition, ultrasonic waves, used in the right way, can produce a number of very special acoustic effects and phenomena.

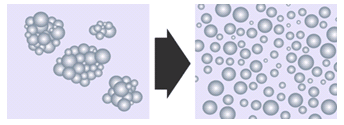

One of these unusual phenomena is acoustic cavitation, which occurs when a powerful ultrasound wave is directed into a liquid. In a liquid, in the region of ultrasonic action, small bubbles of vapor or gas (submicroscopic size) begin to grow to fractions of a millimeter in diameter, pulsating with the frequency of the wave and collapsing in the positive pressure phase.

The collapsing bubble locally generates a high-pressure pulse measured in thousands of atmospheres, becoming the source of spherical shock waves. Acoustic microflows generated near such pulsating bubbles have been useful for preparing emulsions, cleaning parts, etc.

By focusing ultrasound, sound images are obtained in acoustic holography and sound vision systems, and the sound energy is concentrated to form a directional beam with defined and controlled directivity characteristics.

Using an ultrasonic wave as a diffraction grating for light, it is possible to change the refractive indices of light for various purposes, since the density in an ultrasonic wave, as in an elastic wave, generally changes periodically.

Finally, the characteristics related to the speed of propagation of ultrasound. In inorganic media, ultrasound propagates at a speed that depends on the elasticity and density of the medium.

As for organic media, here the speed is affected by the boundaries and their nature, that is, the phase speed depends on the frequency (dispersion). Ultrasound decays with the distance of the wave front from the source — the front diverges, the ultrasound is scattered, absorbed.

The internal friction of the medium (shear viscosity) leads to the classical absorption of ultrasound, moreover the relaxation absorption for ultrasound is superior to the classical one. In gas, ultrasound is weakened more strongly, in solids and in liquids, it is much weaker. In water, for example, it breaks down 1000 times slower than in air. Thus, the industrial applications of ultrasound are almost entirely related to solids and liquids.

The use of ultrasound

The use of ultrasound is developing in the following directions:

- ultrasound technology, which allows producing irreversible effects on a given substance and on the course of physico-chemical processes by means of ultrasound with an intensity of units of W / cm2 to hundreds of thousands of W / cm2;

- ultrasonic control based on the dependence of the absorption and speed of ultrasound on the state of the medium through which it propagates;

- ultrasonic location methods, signal delay lines, medical diagnostics, etc., based on the ability of ultrasonic vibrations of higher frequencies to propagate in rectilinear beams (rays), follow the laws of geometric acoustics and at the same time propagate at relatively low speed.

Ultrasound plays a special role in the study of the structure and properties of a substance, since with their help it is relatively easy to determine the most diverse characteristics of material environments, such as elastic and viscoelastic constants, thermodynamic characteristics, forms of Fermi surfaces, dislocations , crystal lattice imperfections, etc. The relevant branch of the study of ultrasound is called molecular acoustics.

Ultrasound in echolocation and sonar (food, defense, mining)

The first prototype of sonar was created to prevent ship collisions with ice blocks and icebergs by the Russian engineer Shilovsky together with the French physicist Langevin in 1912.

The device uses the principle of sound wave reflection and reception. The signal was aimed at a certain point, and by the delay of the response signal (echo), knowing the speed of sound, it was possible to estimate the distance to the obstacle that reflected the sound.

Shilovsky and Langevin began an in-depth study of hydroacoustics and soon created a device capable of detecting enemy submarines in the Mediterranean at a distance of up to 2 kilometers. All modern sonars, including military ones, are descendants of this device.

Modern echo sounders for studying the bottom relief consist of four blocks: a transmitter, a receiver, a transducer and a screen.The function of the transmitter is to send ultrasonic pulses (50 kHz, 192 kHz or 200 kHz) deep into the water, which propagate through the water at a speed of 1.5 km/s, where they are reflected by fish, stones, other objects and below, after this echo reaches the receiver, a converter is processed and the result is shown on the display in a form convenient for visual perception.

Ultrasound in the electronic and electrical industry

Many areas of modern physics cannot do without ultrasound. The physics of solids and semiconductors, as well as acoustoelectronics, are in many ways closely related to ultrasonic research methods — with effects at a frequency of 20 kHz and higher. A special place here is occupied by acoustoelectronics, where ultrasonic waves interact with electric fields and electrons inside solid bodies.

Volumetric ultrasonic waves are used in delay lines and in quartz resonators to stabilize the frequency in modern electronic systems for processing and transmitting information. Surface acoustic waves occupy a special place in bandpass filters for television, in frequency synthesizers, in devices for transmitting acoustic waves, in memory and image reading devices. Finally, correlators and convolvers use the transverse acoustoelectric effect in their operation.

Radioelectronics and ultrasound

Ultrasonic delay lines are useful for delaying one electrical signal relative to another.An electrical pulse is converted into a pulsed mechanical vibration with an ultrasonic frequency, which propagates many times slower than an electromagnetic pulse; the mechanical vibration is then converted back into an electrical pulse and a signal is produced that is delayed relative to the original input.

For such conversion, piezoelectric or magnetostrictive transducers are usually used, which is why delay lines are also called piezoelectric or magnetostrictive.

In a piezoelectric delay line, an electrical signal is applied to a quartz plate (piezoelectric transducer) rigidly connected to a metal rod.

A second piezoelectric transducer is connected to the other end of the rod. The input transducer receives the signal, generates mechanical vibrations that propagate along the rod, and when the vibrations reach the second transducer through the rod, an electrical signal is produced again.

The speed of propagation of vibrations along the rod is much smaller than that of an electrical signal, therefore the signal passing through the rod is delayed relative to the input by an amount related to the difference in the speeds of electromagnetic and ultrasonic vibrations.

The magnetostrictive delay line will contain the input transducer, magnets, sound wire, output transducer and absorbers. The input signal is applied to the first coil, ultrasonic frequency oscillations - mechanical oscillations - start in the acoustic conductor of the rod made of magnetostrictive material - the magnet creates here permanent magnetization in the transformation zone and initial magnetic induction.

In the rod, vibrations propagate at a speed of 5000 m / s, for example, for a rod length of 40 cm, the delay will be 80 μs. Attenuators at both ends of the rod prevent unwanted signal reflections. Magnetostrictive disturbances will cause a change in the induction in the second winding (output converter) EMF.

Ultrasound in the manufacturing industry (cutting and welding)

An abrasive material (quartz sand, diamond, stone, etc.) is placed between the ultrasound source and the workpiece. Ultrasound acts on abrasive particles, which in turn hit the part with the frequency of ultrasound. The material of the workpiece under the influence of a huge number of small blows from abrasive grains is destroyed - this is how processing is carried out.

Cutting is added with the feed motion, while longitudinal cutting oscillations are the main ones. The accuracy of ultrasonic treatment depends on the size of the grains of the abrasive and reaches 1 micron. In this way, complex cuts are made, which are necessary in the production of metal parts, grinding, engraving and drilling.

If it is necessary to weld dissimilar metals (or even polymers) or to combine a thick part with a thin plate, ultrasound again comes to the rescue. This is the so-called cold ultrasonic welding… Under the influence of ultrasound in the welding zone, the metal becomes very plastic, the parts can very easily rotate during joining at any angle. And it is worth turning off the ultrasound - the parts will immediately connect, catch.

It is especially remarkable that the welding is carried out at a temperature below the melting point of the parts, and their connection actually takes place in a solid state. But steels, titanium and even molybdenum are welded in this way. Thin sheets are the easiest to weld. This method of welding does not imply special preparation of the surface of the parts, this also applies to metals and polymers.

Ultrasonic testing is used to detect flat-type defects in the metal during welding (cracks, lack of penetration, lack of adhesion). This method is very effective for fine grain steels.

Ultrasound in metallurgy (ultrasonic flaw detection)

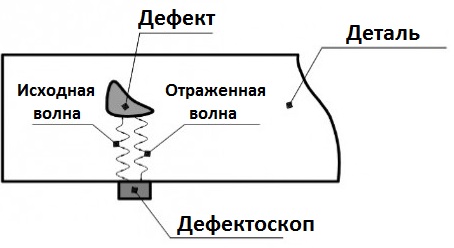

Ultrasonic detection of defects — detection of defects based on changing the propagation conditions of elastic, mainly ultrasonic vibrations.

Ultrasonic flaw detection is one of the most effective methods for non-destructive quality control of metal parts.

In a homogeneous medium, ultrasound propagates in a direction without rapid attenuation, and reflection is characteristic of it at the boundary of the medium. So metal parts are checked for voids and cracks inside them (air to metal interface) and increased metal fatigue is detected.

Ultrasound can penetrate a part at a depth of 10 meters, and the size of the detected defects is of the order of 5 mm. There are: shadow, pulse, resonance, structural analysis, visualization, — five methods of ultrasonic flaw detection.

The simplest method is ultrasonic shadow defect detection, this method is based on the attenuation of an ultrasonic wave when it encounters a defect when passing through a part, as the defect creates an ultrasonic shadow.Two converters work: the first emits a wave, the second receives it.

This method is insensitive, a defect is detected only if its influence changes the signal by at least 15%, in addition, it is impossible to determine the depth where the defect is located in the part. More accurate results are obtained by pulsed ultrasound method, it also shows the depth.

For emitting and receiving elastic vibrations are used piezoelectric transducers, and in the range of sound and low ultrasonic frequencies — magnetostrictive transducers.

The following methods are used to transfer elastic vibrations from the transducer to the controlled product and vice versa:

- contactless;

- dry contact (mainly for low frequencies);

- contact with a lubricant (before the test, a layer of oil or water with a thickness much smaller than the elastic wavelength is applied to the cleanly processed surface of the product);

- jet contact (through a stream of liquid flowing in a small gap between the piezoelectric element and the surface of the product);

- immersion (the controlled product is immersed in a bath and contact is made through a layer of liquid, the thickness of which must be at least 1/4 of the thickness of the product).

The advantage of immersion, inkjet and non-contact methods is the lack of wear on the search heads and the possibility of using higher scanning speeds, as well as the possibility of automation of management.

See also:

Installations for ultrasonic cleaning of parts

Ultrasonic sensors for automation systems

Sensors and measuring devices for determining the composition and properties of substances