Electrical equipment for crushing machines and concrete mixers

The crushing plant consists of a receiving hopper, a feeder for crushers, the crusher itself and a conveyor. The crushed material enters the conveyor for further transportation to production.

The majority of crushing machines use electric drives with squirrel-cage asynchronous rotor motors of closed or protected design with moisture-proof insulation. Irreversible magnetic starters are used as starting devices. The power of electric motors for stone crushers, sieves, concrete mixers and other similar mechanisms is selected on the basis of experimental data.

Rock crushers with engines above 15-20 kW are equipped with heavy load balancing flywheels, i.e. taking sudden bursts of overload due to their own kinetic energy. These rock crushers are equipped with phased rotor motors to ensure high starting torques and smooth start.

The power of the engines of the main types of stone crushers depends on the diameter of the feed hole, the productivity and varies from 18 to 280 kW. The power of the drive motor of medium and fine crushing jaw crushers is selected not according to the starting conditions, but according to the static load moment, while the motor power varies from 20-175 kW, for cone crushers-40-200 kW, and for hammer- crushers –25-200, depending on productivity.

The control equipment of the crusher must provide maximum current protection, because overloading of the motor is possible due to the penetration of solid objects (metal) into the crusher, which leads to jamming of the crusher.

Drum sieves (gravity sorting) are produced with a 3-7 kW drive motor, and horizontal inertial sieves with a power of 5 kW. Modern crushing plants and similar machines have a high degree of automatic protection against overloading, overheating of bearings and metal objects. There is an automatic adjustment of the productivity and operation of the conveyors, depending on the lumps of the loaded raw materials.

To remove metal objects from the material flow, metal catchers are used, made in the form of electromagnetic rollers or suspended DC electromagnets powered by separate rectifiers.

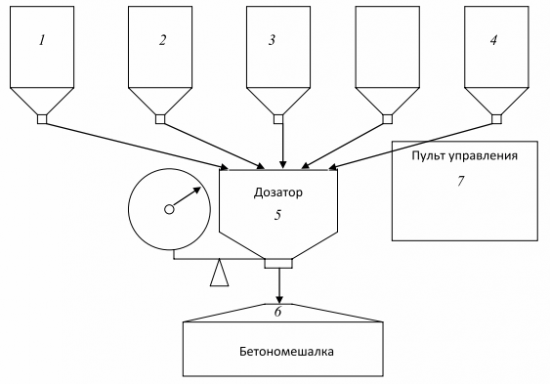

Concrete mixers used in factories and depots for the production of reinforced concrete products are a complex consisting of feed containers 1, 2, 3, 4, a dispenser with a weighing head 5, a concrete mixer 6 and a control panel 7. In addition, concrete mixers are also equipped with mechanisms that are not directly related to the preparation of the mixture.These are lifting and transport mechanisms, conveyors, pumps for pumping cement and water, transport carts for delivery of the mixture to molding workshops, etc.

In most factories, the process of preparing concrete mixture is automated. These are electric and pneumatic systems that, at the command of the operator who sets the grade of concrete and starts the system, independently dose the components of the mixture according to the program, load them into the concrete mixer and, when the mixture is ready, unload it into vehicles. Pneumatic systems are have proven themselves well, which are not afraid of disturbances and dustiness of the working environment, unlike electrical systems.

Block diagram of a concrete mixer

The operator's console, as a rule, is moved to another room, since the process of preparing the concrete mixture is noisy and dusty. Squirrel rotor asynchronous motors are used for the electric drive of the concrete mixer. The power of the drive motor varies depending on the volume of the drum. For example, for a volume of 250 liters, the power of the engine is 2.8 kW, and for a volume of 2400 liters - 25 kW. That is, for every 100 liters of drum volume, there is approximately one kilowatt of engine power.

The total power of all engines of a concrete mixer with a performance of 10 m3 / h (with two concrete mixers of 250 liters each) is about 30 kW. With a capacity of 125 m3 / h (two concrete mixers of 2400 liters each), the total power is 240 kW. Various sensors, electromagnetic pneumatic cylinders, limit switches and other equipment are used in the automated control system of the concrete mix preparation process.