Explosion hazard concept, explosion-proof electrical equipment

In the enterprises of the chemical, oil refining and other industries, the production process is associated with the formation of various flammable liquids and combustible gases. Nap: In the production of artificial fibers, combustible gas hydrogen sulfide is used, in the nitrogen industry - ammonia, in the production of synthetic rubber - acetylene, etc.

In the refining industry, crude oil is the starting product for refining.. V As a result of processing, a large number of different products are obtained, including flammable and combustible liquids - gasoline, kerosene, toluene, etc.

At the same time, the technological process of oil refining is accompanied by the release of vapors from these liquids and the associated combustible gases (ethane, propane, butane, etc.) inside the equipment and pipelines.

In the event of malfunctions or accidents, flammable gases and vapors from flammable liquids can enter the environment and form explosive mixtures when mixed with atmospheric oxygen or other oxidizing agents (e.g. chlorine).

The explosion hazard of the products is characterized by the ignition temperature and the self-ignition temperature of flammable gases or vapors of flammable liquids. A mixture of flammable gases and vapors of flammable liquids with air becomes explosive only at a certain concentration and has an upper and lower explosion limit.

The explosive concentration of gas and vapor-air mixtures is determined in volume percentages, the values of which are given in special tables.

Explosive mixtures with air can also form dust and fibers of certain substances when they pass into a suspended state (for example, coal dust, powdered sugar, flour, etc.).

The explosive concentration of mixtures of combustible dusts and fibers with air is determined in g / m. According to the «Rules for the construction of electrical installations», combustible dust and fibers are classified as explosive if their lower explosion limit does not exceed 65 g / m3.

When developing the design of electrical equipment for explosive installations, the physical properties of the explosive mixtures in which they are intended to work are taken into account.

Explosive mixtures of flammable gases and vapors are divided into categories and groups depending on their physical properties.

The category of explosive mixtures is determined by the size of the gap (slots) in the flange joints of the equipment housing, through which their explosion is not transferred from the housing to the environment.

Depending on the transmission of the explosion through the flange gaps, four (1, 2, 3 and 4) categories of explosive mixtures are established in the enclosure.

The explosive mixture group is determined by the auto-ignition temperature, depending on which explosive gas and vapor-air mixtures are divided into four groups (A. B, D and E).

In order to avoid the occurrence of an explosion, the temperature of parts of electrical equipment in contact with an explosive atmosphere must in all cases be significantly lower than the self-ignition temperature of an explosive mixture of this group.

Premises and external installations in which, according to the conditions of the technological process, explosive mixtures with air of combustible gases, vapors of flammable liquids, as well as combustible dusts and fibers when they pass into a suspended state can be formed, are called explosive.

Explosive installations are divided into classes B-I, B-Ia, B-Ib, B-Азd, B-II and B-IIa.

Class B-I includes rooms in which flammable gases and vapors are emitted, and class B-II - rooms in which vapors and fibers are emitted, passing into a suspended state and forming explosive mixtures with air or other oxidizers in normal short-term modes of operation.

Class B-Ia rooms are characterized by the possibility of emitting flammable gases and vapors, and class B-IIa rooms are characterized by combustible dust and fibers that form explosive mixtures with air only as a result of an accident or malfunction.

Premises of class B-Ib - these are the same premises as class B-Ia, but differ in one of the following characteristics:

-

flammable gases in these rooms have a high lower limit of explosivity (15% or more) and a sharp smell at the maximum permissible concentration according to sanitary standards (for example, compressor stations with ammonia);

-

the presence of flammable gases and flammable liquids in small quantities that do not create a general explosive concentration, and work with them is carried out without an open flame (these installations are classified as non-explosive if they work in burnt or under burnt gas hoods).

Class B-1d includes outdoor installations containing flammable gases and liquid vapors (eg gas tanks, containers) in the vicinity of which explosive mixtures may occur in the event of an accident or malfunction.

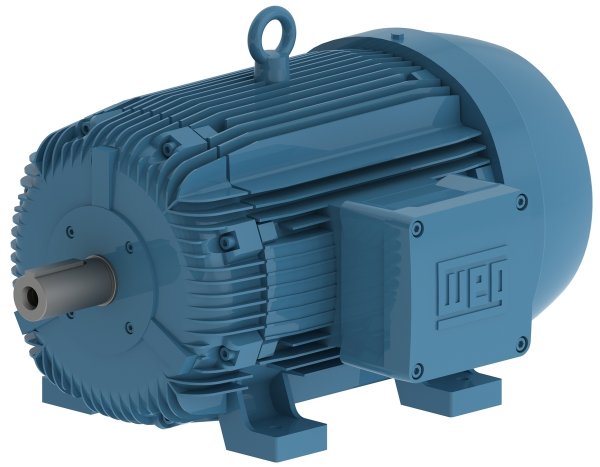

For work in explosive installations, special explosion-proof electrical equipment (machines, devices, lamps) must be used, the design of which must ensure the safety of use in explosive environments.

Such equipment must meet the following basic requirements:

-

have increased mechanical, anti-moisture, chemical and thermal resistance of the coil, which will to some extent prevent the possibility of damage to the insulation of the coil and the appearance of sparks;

-

normally sparking parts of machines and apparatus (e.g. slip rings of machines, contacts of starters, etc.) must be placed in a closed fireproof enclosure;

-

the current supply must be carried out in special input devices adapted to introduce a cable or wire into a steel pipe;

-

for electric machines, ball bearings must be used.

Explosion-proof electrical equipment can be of different designs:

-

Explosion-proof;

-

Increased reliability against explosion;

-

Filled with oil;

-

Blown under excess pressure;

-

Intrinsically safe;

-

Special.

The choice of execution of electrical equipment is made by the design organization and depends on the class of blasting installation in which it will work. The type of execution, as well as the category and group of explosive mixture in the environment in which this equipment can work, is determined by the symbols available on the equipment.

More detailed characteristics of the equipment are given in «Rules for the construction of electrical installations» (chapter 7-3, Electrical installations in hazardous areas) and in the "Rules for the manufacture of explosion-proof electrical equipment".

Only water and gas pipes can be used for the installation of electrical cables in potentially explosive areas. The use of electrically welded (thin-walled) pipes, as well as non-standard water and gas pipes, is not allowed.

Connecting pipes to each other, as well as to electrical machines, devices, lamps, etc., is done only on a thread. It is not allowed to use welding to connect pipes and attach them to structures to avoid burning.

Connecting, branching and pulling wires in long sections is done in special explosion-proof boxes. The type of box and the brand of wires laid in the pipes are determined by the project.

In order to prevent the possibility of transmission through the pipes of an explosion that happened accidentally in a machine or apparatus, and to limit the area of its action, separation seals are installed on the pipelines.

The place of installation of the pipes of the separation seals is usually indicated in the projects.Regardless of the design instructions, separation seals must be installed at the points of entry of steel pipes in electrical machines and devices, when the pipelines pass from one blast room to another (explosive or normal) or outside.

When opening in explosive installations, steel pipes of electric wires are firmly fixed along the entire length, as well as at the points of entry into machines, apparatus, lamps, etc. structures.

The openings through which the pipes leave explosive areas are tightly sealed with non-combustible materials (for example, clay or cement screed), so as to exclude the connection of adjacent rooms and the penetration of gases through cracks and gaps.

See also on this topic:Intrinsically safe electric circuit type of explosion protection