Microprocessor-based relay protection devices: overview of possibilities and controversial issues

About 15 years ago, new power equipment protection equipment using processor-based computer technology began to be widely introduced in the power industry. It came to be called the abbreviated term MPD — microprocessor-based relay protection devices.

About 15 years ago, new power equipment protection equipment using processor-based computer technology began to be widely introduced in the power industry. It came to be called the abbreviated term MPD — microprocessor-based relay protection devices.

They perform the functions of ordinary devices for relay protection and automation based on a new element base — microcontrollers (microprocessor elements).

Advantages of microprocessor relay protection devices

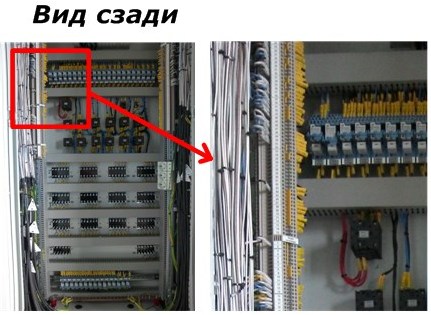

The rejection of electromechanical and static relays, which have significant dimensions, made possible a more compact placement of equipment on relay protection and automatic panels. Such designs began to take up significantly less space. At the same time, control using touch buttons and the display has become more visual and convenient.

The external view of the panel, including the microprocessor relay protection, is shown in the figure.Now the introduction of MPD has become one of the main directions in the development of relay protection devices. This is facilitated by the fact that in addition to the main task of relay protection and automation — the elimination of emergency modes, new technologies allow implementing a number of additional functions.

They include:

-

registration of emergency conditions;

-

predicting the disconnection of synchronous users in case of system stability violations;

-

ability to shorten long distances.

The implementation of such capabilities based on electromechanical protection of EMI and analog devices is not carried out due to technical difficulties.

Microprocessor-based relay protection systems operate on exactly the same principles of speed, selectivity, sensitivity, and reliability as conventional relay protection devices.

During operation, not only the advantages, but also the disadvantages of such devices were revealed, and according to some indicators, disputes between manufacturers and operators are still ongoing.

RZA panels equipped with microprocessor protection

disadvantages

Many buyers of microprocessor-based relay protection devices have been dissatisfied with the performance of these systems due to:

-

high price;

-

low maintenance.

If in case of failure of devices operating on a semiconductor or electromechanical basis it is enough to replace an individual defective part, then for microprocessor protection it is often necessary to replace the entire motherboard, the cost of which can be a third of the cost of the entire equipment.

In addition, replacement will require spending a lot of time looking for a part: interchangeability in such devices is completely absent even in many of the same type of designs from the same manufacturer.

Electromechanical relays have been operating successfully for over 35 years

Controversial issues

1. High reliability of microprocessor relay protection devices compared to electromechanical protection

Manufacturers of microprocessor devices with advertising emphasize the absence of moving parts in the system, which is related to the exclusion of mechanical wear conditions. Also added here are the issues of metal corrosion and insulation aging in electromechanical and semiconductor based structures.

The experience with the operation of electromechanical protection is already about a century and a half. The majority of energy enterprises in Russia and CIS partners work on this basis. Many relays have been powered for several decades, and the developed system of maintenance and operation allows them to be guaranteed to be used for quite a long time.

In fact, insulation defects and corrosion can occur in only two cases:

-

violation of production technology;

-

deviation from the rules of operation and maintenance.

If we consider the issue of mechanical wear of moving parts, then it should be borne in mind that they are triggered only during checks by personnel carried out after several years (taken into account from the time of operation) or in accidents that happen a lot rarely.

At the same time in microprocessor devices for relay protection:

-

most components constantly monitor the electrical circuit and exchange signals with each other;

-

the elements of the electrical inputs are constantly exposed to a high voltage of 220 volts, as well as to impulse and peak values of transient processes;

-

the high-speed pulse circuit power units operate without shutdown with the release of heat and form the main share of MPD failures.

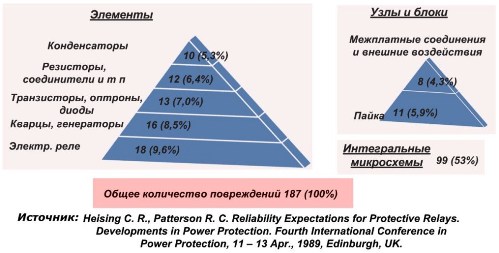

2. Relay reliability gradually increased from electromechanical designs to semiconductor designs based on discrete components, then to integrated circuits and the highest among microprocessor devices

Statistics show higher reliability of electromechanical relays compared to semiconductor analogs in daily use. The opposite picture is observed only when the switching cycles are increased to several hundred thousand or millions.

Integrated circuits employ a much larger number of electronic elements that are less resistant to overvoltage than in solid state relays. This is especially true when exposed to static electricity and electromagnetic noise, which are constantly present in high-voltage power equipment.

The statistics of failures of microprocessor relay protection devices of Japanese companies refute the myth of the highest reliability of microprocessor protection. Also, this does not include "software failures", which often cannot be detected during inspections, but can occur at any time.

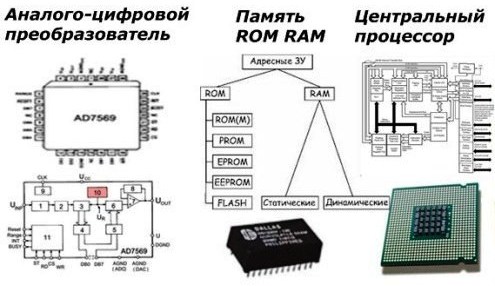

3. The reliability of microprocessor relay protection devices is improved by built-in self-diagnostics

Microprocessor-based defenses include:

-

analog-to-digital converters;

-

memory (ROM — ROM + RAM — RAM);

-

PROCESSOR;

-

power supply;

-

output electromagnetic relays;

-

nodes of analog and digital inputs.

Composition of blocks of microprocessor relay protection

All these components are covered in different ways by self-diagnosis algorithms and are not always fully controlled.

The internal check is designed to signal and block the operation of the relay protection in the event of a fault in its circuit, not in the power company's electrical network. Therefore, it does not increase the reliability of the power system.

4. The reliability of microprocessor-based relay protection devices is higher because its components are more resistant to physical aging

With proper operation, the electromagnetic protection relays introduced in the USSR in the 1970s still work perfectly and have retained their technical characteristics.

Electrolytic capacitors of even the best companies in Japan, which are part of the relay protection, after 7 years of operation in switching power supplies lose their properties, tightness and create electrolyte leaks that can corrode the copper tracks of the circuit boards.

MPD damage statistics of Japanese companies

Microprocessor device manufacturers have seen a desire to reduce the size of electronic components by creating modes with increased heat dissipation that must be removed from the cooling system, which is not always done.

Difficulty at work

1. Electromagnetic compatibility

Modern microelectronics is very sensitive to electromagnetic radiation, and sets of microprocessor relay protective devices are installed at substations operating in conditions of increased electric field strength, requiring reliable shielded protection with accumulated potential drain to earth.

In many substations, the resistance of the ground loop does not meet the requirements for the operation of microprocessor relay protection devices, which implies a large amount of construction work. Otherwise, such protections can lead to unauthorized operation in the event of electromagnetic disturbances in the system, which can easily be created intentionally, such as hacker attacks against software.

2. Tasks to be completed

The failure of one microprocessor protection leads to more serious consequences for electricity than the failure of electromagnetic protection, because functionally the microprocessor relay protection device performs the tasks of 3 ÷ 5 electromagnetic protection.

3. Staff training

A huge number of companies in the world with a turnover of more than billions of dollars are engaged in the production of microprocessor devices for relay protection. In Russia and the CIS countries alone, more than 10 enterprises operate on the world market.

Each security device is made using a unique technology that excludes the interchangeability of elements and software. Technical descriptions with instructions for use are multi-page books with several hundred A4 sheets. It takes a lot of time and prior specialized knowledge to study them.

When a new type of microprocessor-based relay protection device arrives, even from the same manufacturer, the personnel training process must be restarted.

conclusions

Microprocessor-based relay protection devices are a truly progressive direction in the development of electricity.

The high reliability of microprocessor devices for relay protection, announced by manufacturers, does not always correspond to reality.

Personnel servicing any microprocessor protection unit must be aware of all the weaknesses of such devices and skillfully correct their operation.

It is high time that government agencies take up standardization issues and bring microprocessor-based relay protection systems into them.

Gurevich VI Vulnerabilities of microprocessor protective relays: problems and solutions. — M.: Infra-engineering, 2014 — 248 p.: Il.