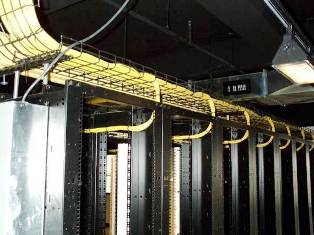

Metal cable trays

For the production of cable trays, high-quality steel with a protective zinc coating is used, which prevents the formation of corrosion. Cable trays are used in laying cables and wiring during the installation of power lines. They perform an important function — they protect wires from external factors and damage. Today, there are practically no buildings in which they were not used for laying wires. metal cable trays.

For the production of cable trays, high-quality steel with a protective zinc coating is used, which prevents the formation of corrosion. Cable trays are used in laying cables and wiring during the installation of power lines. They perform an important function — they protect wires from external factors and damage. Today, there are practically no buildings in which they were not used for laying wires. metal cable trays.

All metal cable trays are divided into:

• Perforated;

• Hard;

• Wire;

• Staircase.

Perforated cable trays

Their main function is to hold and protect wires and cables during the entire period of operation. If you use various additional elements (covers, plates), you can increase the degree of protection of the device. This makes it possible to use such trays even in difficult working conditions, for example in rooms with high humidity.

Perforated cable channel — this is a metal channel that includes straight elements with a perforated base. It also has the names of metal cable channel or cable channel.But whatever the name of this panel, it is a high-quality and sought-after device used for laying electrical cables and wires in various facilities.

The perforated cable tray can be installed with or without a cover. The cover provides an increased level of protection of the wires from negative environmental influences. Therefore, the coating makes it possible to significantly increase the scope of this design. Perforated tray is considered the best option for creating cable routes and wiring for which the voltage does not exceed 1000 V.

The main design feature of the perforated tray is the lateral perforation, which looks like holes located along the entire length of the structure. This greatly facilitates the installation of cables and wiring, as well as the installation of the tray cut into non-standard segments. What's more, there are round holes at the base of the structure for quick and easy attachment of corrugated or rigid cables. The perforation can prevent the wires that are inside the tray from overheating or catching fire.

Another feature of the perforated cable tray is the stamped edge that helps create a quick overlap. There is a ground connection on the lids, which makes the use of perforated trays completely safe for the human body.

Perforated metal cable channel has three options:

• stainless steel;

• made of hot-dip galvanized steel;

• made of galvanized steel.

The main option is galvanized steel. The galvanizing process is carried out as follows: a heated metal sheet is immersed in a bath containing molten zinc.In this way, a dense, uniform layer of zinc is obtained, which makes the pan corrosion-resistant and extends its service life. Galvanized cable trays are the most popular in this series.

The perforated galvanized tray ensures the installation of cables and wires not only indoors, but also outdoors. It is also indispensable in solving issues related to the distribution of the main communications with electricity - telephone, television, industrial, etc. Due to the presence of technical openings in the perforated galvanized tray, the cable is easier to check. In addition, these trays are easy to install (to the ceiling or walls).

There are also "galvanized non-perforated cable trays", which are also used for laying protection of wires and cables from external influences. The flat cover, tightly fitting to the structure, is able to reliably protect the cable from external influences, while providing easy access to the wires. The use of such structures is possible both indoors and outdoors. A distinctive feature of perforated galvanized tray and non-perforated is high fire safety, that is, a cable fire will occur inside the tray and will not go outside its boundaries.

Methods of fastening and installation of cable trays

Since the trays are highly stressed by the large amount of cables to be laid, reliable methods of installation and fastening must be used. For convenience, all mounting options are presented in three groups: fixing to the floor, to the ceiling or to the wall.

Mounting cable trays to the wall is a popular method of installation, which is carried out thanks to cable shelves (wall brackets, brackets, bracket brackets).In turn, the cable racks are attached directly to the wall or on special profiles (stands), due to which durability and reliability are ensured.

The main advantage of using cable racks is the possibility to install several parallel floors of trays for separate routing of cables. When laying the route vertically, you can use brackets-clamps.

Advantages of using brackets and shelves:

— easy and quick installation;

— high bearing capacity, reliability and strength of the structure;

— flexibility;

— a large range of clamps and shelves for a wide range of loads.

Fixing cable trays to the ceiling

There are the following installation schemes:

— use of stand and bracket;

— using a mounting rack and profile;

— on a C-shaped suspension;

— with a hairpin;

— use of perforated tape;

— attachment to the corrugated board;

— to the ceiling beam;

— using a clip and hairpin.

Recommendations for the method of mounting the cable tray on ceiling racks:

1. Mounting the tray to the ceiling using brackets is reproduced using a ceiling bracket.

2. The fixing of the ceiling bracket is done using anchor bolts or drop anchor. The sliding anchor is driven in with a special tool, after which bolts are installed in it. With the help of an anchor assembly, it is possible to easily sort or dismantle structures.

3. The installation of the ceiling bracket should be done at a distance of 1-1.5 meters from each other.

Recommendations for using perforated steel strip:

1.Mounting on perforated tape is the cheapest solution, but due to insufficient rigidity it has a limited area of application: low load; low suspension height; small width of cable trays; difficulties with the expansion of installed structures.

2. Fastening of the perforated strip is done with bolts that are screwed into the anchors.

3. The fastening of the channels to the perforated strip is done with screws, nuts and washers.

4. In the middle of the tray and at the joints, the distance should be 1-1.5 meters.

Use of studs and mounting profile:

To fix the tray to the ceiling, which is used for laying a large number of wires or cables, as a rule, two spikes and mounting profiles are used, installed between the spikes. When the cable support system has a low load, one bolt fixed in the environment.

This option simplifies and speeds up installation, reduces the cost of structures, but creates limitations on the bearing capacity. It is possible to create several parallel channels, for which the installation of several profiles is used.

Installing the cable tray to the floor

There are several schemes that are variations of the application of the above installation methods:

— use of stand and bracket;

— using a mounting rack and profile;

— using a clamp-clamp.