Accessories and parts for installation and wiring

Assembly products and parts are used in all electrical installations and in all types of electrical work and operations. They are used in the preparation of routes for laying wires, cables, buses and during their laying, fastening, connection and connection to machines, devices and devices, are used for their protection from the influence of the environment and mechanical damage, as well as for installing devices, devices, lamps, etc.

Assembly products and parts are used in all electrical installations and in all types of electrical work and operations. They are used in the preparation of routes for laying wires, cables, buses and during their laying, fastening, connection and connection to machines, devices and devices, are used for their protection from the influence of the environment and mechanical damage, as well as for installing devices, devices, lamps, etc.

Products and parts for laying wires and cables.

A tray is a welded metal grid structure consisting of two parallel profiles or plates (strips). For laying wires and cables, welded and perforated trays are used, which are finished with various parts: corners, corners for separating wires and cables from different circuits, pendants and buckles for fixing cables on welded trays, brackets for attaching trays to cable shelves.

Boxes are rectangular profiles made of sheet metal with removable covers. They make boxes of the following sizes: 60×30, 220×117 mm, etc.The cross-section of a typical box is equivalent to the cross-section of a 2" diameter steel pipe.

Boxes are rectangular profiles made of sheet metal with removable covers. They make boxes of the following sizes: 60×30, 220×117 mm, etc.The cross-section of a typical box is equivalent to the cross-section of a 2" diameter steel pipe.

The boxes are filled with straight sections, crosses, tees, elbows for turning the track in a horizontal plane, vertically up and down, end caps and connecting brackets, as well as auxiliary parts for fastening to building structures - brackets and hangers. The length of the straight section of the box is 3 m. Steel boxes KL-1 and KL-2 are used for laying power wires in them and for hanging fluorescent lamps to them in one and two rows.

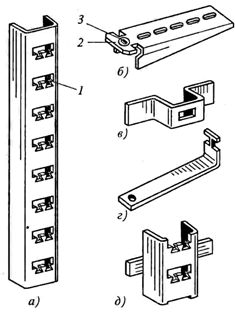

Cable structures intended for laying cables in industrial premises, tunnels, channels and other cable structures are assembled from standard elements - racks and shelves (Fig. 1).

Racks equipped with shelves are fixed in the foundations of the building, cables are laid along the shelves and in horizontal rows. When assembling cable constructions, the shelf stele 2 is inserted into the hole of the rack so that the tongue 1 of the rack fits into the oval hole 3 of the shelf wall.

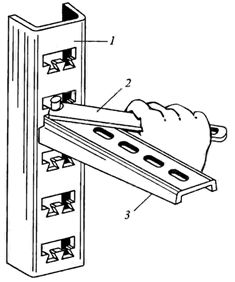

Then, with a special key 2 (Fig. 2), the tongue is rotated 90 °, as a result of which an integral connection of the shelf with the trunk is formed, as well as the necessary electrical contact. The racks can be 400, 600, 800, 1200 and 1800 mm high with the number of oval holes for mounting the shelves 8, 12, 16, 24 and 36 respectively. The length of the shelves is 160, 250, 350 and 450 mm.

Rice. 1. Cable structures: a — rack; b — shelf; c — clamp; g-suspension; d — base; 1 — language; 2 — shank; 3 — an oval hole in the shank

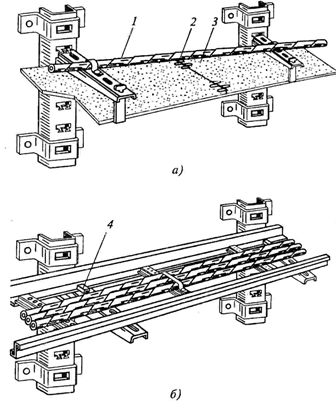

Cables are laid directly on shelves or in trays mounted on them (Fig. 3). Modern cable structures are made of galvanized steel.

Rice. 2.Fastening the shelf to the rack: 1 — rack; 2 — key; 3 — shelf

A variety of prefab cable structures are racks with built-in hangers for laying cables in rows in a vertical plane… In addition to these basic cable management products, some components: brackets for fixing cable racks by aiming; trays for laying connectors on prefabricated cable structures; foundations for mounting one shelf and for laying and connecting asbestos-cement partition walls; hangers and connectors.

Rice. 3. Laying cables on shelves (a) and in trays (b): 1 — cable; 2 — partition connector; 3 — asbestos-cement partition plate; 4 — bracket

Wire connections and branches are made in steel and plastic boxes of different sizes for different types of wiring. Cable and conduit boxes are discussed below.

Perforated steel mounting profiles and strips... Perforated steel products produced by enterprises - strips, pins, channels, rails and other mounting profiles with perforation, ensure the production of various support and fastening structures with minimal labor costs in workshops and during installation . Frames and frames for assembling blocks of shields and starters are obtained from them, they are used for hanging lamps assembled in blocks and fixing pipes, wires and cables.

Application mounting profile with a cage nut allows you to fix pipes, cables, devices without preparing new holes when changing the attachment points. It is easy to make strips, brackets, sleepers from perforated tape. Folded straps make it easy to tie pipes or cables.These buckles have cutouts for fastening in the perforation of the band and rectangular holes for clamps that secure cables or pipes.

Tips and sleeves. For enclosing and connecting wires of wires and cables, the following are manufactured:

• T and P series copper ears;

• copper-aluminum ears from the TAM series and pins from the ŠP series;

• aluminum tips from the TA series and copper bushings from the GM series;

• aluminum bushings of the GA series and bushings for single-core wires of the GAO series;

• branch clamps in plastic case.

Lugs and bushings are used for wires of wires and cables with sections up to and including 240 mm2. Connections and branches of single-core aluminum conductors with a cross section of 2.5 ... 10 mm2 are made in sleeves of the GAO series with one-sided and double-sided filling with their cores. In this case, the maximum total cross-section of all wires is 32.5 mm2. They also manufacture aluminum lugs formed from a rail with longitudinal ribs along the inner tube section.

A new method at the moment is the volumetric stamping of the end fitting from a sector monolithic vein. On a special powder press, an end part with a hole is stamped in one shot, which receives the necessary contact surface in the form of a tip.

The list of installation products of the plants includes products for the installation of busbars and secondary devices, various fasteners, elements for hanging lamps, structures for the equipment of wooden poles for power lines and much more. The types and indexes of these products, their technical characteristics and areas of application are given in the nomenclature indexes of the respective manufacturers.

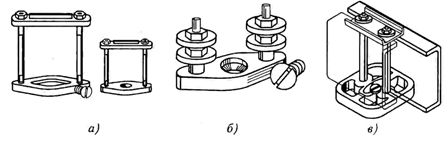

Tire mounting products busbar holders, adapter plates, busbar compensators, busbar spacers, insulating inserts, washers and more.Busbar supports of the ShP and ShR series for fixing flat busbars (single and 2-3 pieces in a package of different sections, width from 40 to 120 mm and thickness from 4 to 12 mm) on plane and edge, as well as busbar holders for fixing profile rails (with a box section) are shown in fig. 4.

To connect aluminum busbars to copper flat or bar terminals of electrical devices and machines, MA series copper-aluminum transition plates and AP series plates of AD31T1 alloy are used. For rail sizes from 4 x 40 to 10 x 120 mm, the length of the plates should be from 100 to 190 mm, their connection is welded.

To compensate for the temperature expansion of the extended sections of the aluminum rail, bus compensators with a width of 50 ... 120 mm and a thickness of 6 ... 10 mm are used. Their connection to the rails is welded.

Rice. 4. Rail supports for fixing flat tires on a plane (a) and edge (b) and for fixing profile rails (c)

To fix the gaps in a package of flat copper and aluminum busbars, spacers for busbars with dimensions of 110x28x8 and 150x22x10 mm are used, for separating bus lines from flat busbars - insulating inserts. Special steel washers of the A8, A10 and A12 series with a thickness of 3 ... 4 mm and a diameter of 18, 22, 28 mm are used for bolted joints of aluminum tires, as well as for AC-12 and Series AC-16 with a thickness of 4 and 6 mm and diameter 34, 38 mm.

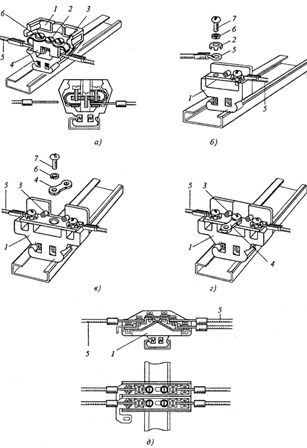

Clips (Fig. 5) are used to connect the wires of the secondary circuits laid along the panels with control cables. They are distinguished by design:

• for normal clamps of the KNB series, used for hands-free (plug-in) connection of wires of wires and cables with a section of 1.5 ... 6 mm2;

• normal clamps of the KN series, intended for connecting two conductors of different sections of the circuit with a section of 1.5 ... 6 mm2. In this case, the ends of the wires and cable cores are bent into a ring;

• special clamps of the KS-3M series, used for connecting two wires and connecting them to adjacent similar clamps, as well as for connecting strands of wires bent into a ring. One of them is a special terminal clamp of the KSK-ZM series, designed for installing a jumper with KS-ZM type clamps in the absence of devices in the current transformer circuit (in the terminal clamp, the jumper is installed only on one side; the design of such a clamp provides for the connection of a wire core with a section of 1.5 ... 6 mm2, bent into a ring);

• panel test clamps of the ZSCHI series, designed for testing and testing secondary circuits. The design of the clamp allows you to connect several wires with the same purpose (one wire for each screw contact).

A test clamp is a plastic base with a brass contact piece fixed on it, consisting of two curved contact strips connected by a bridge. These clamps are fixed on K109 rails with a plastic base and a spring. This design allows you to install and replace clamps anywhere along the rail — end and middle. Fixation and marking of groups of inlaid brackets is carried out using marking blocks of the KM-5 series.

For the wiring of secondary circuits, other products are also produced: star-shaped washers for connecting aluminum wires of control cables, end labels and plastic marking labels, bushings, ferrules, pipes, etc.

Rice. 5.Adjustment clamps: a — normal series KNB; b — normal KN series; c — special series KSK-ZM; g — special final series KS -3M; d — ZSCHI test series; 1 — case; 2, 6 — spring and limiting washers, respectively; 3 — contact spring; 4 — insert for hands-free (end) connection of wires; 5 — conductor of secondary circuits; 7 — screw.