Thermite welding: types, advantages, applications

Thermite welding is based on the ability of some powdered mechanical mixtures of metals with metal oxides (thermites) to burn, releasing a large amount of heat.

Thermite welding is based on the ability of some powdered mechanical mixtures of metals with metal oxides (thermites) to burn, releasing a large amount of heat.

Iron oxide (iron oxide) is used as oxides in thermite mixtures, and aluminum, magnesium, etc. are used as combustible metals. The source of oxygen in thermite is iron oxide, and the source of heat is the metal included in the mixture in its pure form.

In order to produce a thermal effect, the amount of heat given off in the combustion of a combustible substance must be greater than that required for the decomposition of the oxide. Thermite welding is characterized by the burning of the thermite within a few seconds, during which time the entire amount of heat is released.

Types of thermite welding and their application

Distinguish between thermite-crucible and thermite-muffle welding KS.

Dry powdery thermite mixtures are used for thermite-crucible welding. When welding steel strips and rods ground loops use aluminum thermite consisting of 23% aluminum dust and 77% scale (by weight). The percentage of aluminum and iron scale in the thermite mixture varies according to the grade of the scale and the purity of the aluminum dust. To increase the yield of iron released during thermite combustion, as well as to lower the reaction temperature, steel waste from the nail industry is added to thermite.

In thermit welding of steel bars and strips, a steel insert (a circle that closes the crucible hole) is used for the same purposes. The intensity of the termite burning process depends on the grain size of the components. Granular grains with a size of 0.25 to 1.5 mm are used for a stable welding process. In order to improve the quality of the welded joint, alloying additives — 80% ferromanganese and ferrosilicon in quantities of 1.4 and 0.15% by weight, respectively — are introduced into thermite mixtures.

The peculiarity of thermite-crucible welding is that the ends of the rods to be joined are melted and joined by the metal formed by the burning of the thermite mixture.

To connect steel single-core wires of communication lines, use cylindrical thermite pools with a through longitudinal hole. The opening corresponds to the diameter of the wires to be welded. Thermite blocks are pressed from a mixture containing 25% pyrotechnic magnesium of the MPF brand and 75% iron rock. Nitrolac grade NTs-551 is used as a binder, which is added in an amount of about 14% of the mass of the dry mixture (over 100% of the mixture).

Thermite crucible method is unsuitable for welding aluminum wires.Use heat quench welding in the form, as used for steel welding, when there is direct contact between the muffle block and the aluminum wire, this is unacceptable for a number of reasons:

1. when the thermite muffle burns, the aluminum reacts, causing the metal to burn on the surface of the wires being welded,

2. the products of the reaction fall into the aluminum of the weld pool and deteriorate the characteristics of the joint,

3. the wires at the exit from the thermite muffle melt, which leads to a reduction in their cross-section; when welding multi-core wires, the individual wires of the core burn.

For welding multi-core wires, we have developed thermite cartridges, which are a thermite block with a metal cooling form... In thermite-muffle welding (as opposed to thermite-crucible), as a result of thermite combustion, the reaction products do not appear in liquid form. In the process of burning, a porous mass of magnesium oxide is formed, which absorbs molten iron, due to which the magnesium thermite does not produce liquid, dispersing slag.

The thermite mass recipe for the production of thermite blocks for cartridges of types PA, PAS, etc. It is the same as for the production of thermite blocks for connecting steel single-core wires.

Welding of aluminum and its alloys is hampered by a film of aluminum oxide that quickly covers it in air. Therefore, the removal of oxides and the protection against further oxidation of the weld pool are of great importance in welding.

The effect of the oxide film is reduced by flows, with which the connected wires and filler rods are covered before welding.The flux dissolves the oxide and turns it into a low-melting slag that floats to the surface. In this case, a film of liquid slag covers the surface of the molten metal of the weld pool during welding, isolates this surface from air and thus protects against further oxidation. The remnants of the stream, however corroded wires, therefore, when implementing KS, we should, if possible, avoid using streams.

One of the best is the AF-4A flux, which contains sodium chloride — 28%, potassium chloride — 50%, lithium chloride — 14%, sodium fluoride — 8% (by weight). This flow can be used only in cases where the welded connection is completely protected from external influences.

Significantly less corrosion is caused by the three-component flux VAMI (potassium chloride — 50%, sodium chloride — 30%, cryolite class K -1 — 20%). However, even when using it, it is necessary to take measures to protect the joints from corrosion. Flux residues on the torch after welding must be removed by stripping or washing.

When welding aluminum wires with a thermite cartridge, a filler rod is introduced into its injection hole, which is melted to increase the liquid metal in the cooling mold. Aluminum rods or bare wires of the welded wires are used as filler rods. Fillers are made by twisting several wires with a diameter of 2 mm, previously degreased and cleaned.

The benefits of thermite welding

Thermite welding is favorably distinguished by independence from sources of electricity or gas, without the need for complex equipment, as well as the ability to make connections in linear conditions by installation, repair and service personnel.

Thermit welding of bare wires

It is most economical to connect wires to high-voltage power lines by thermal welding. This method does not require complex equipment and special tools.

Thermit welding of wires, if carried out in full accordance with the established technology, is the simplest and most reliable way of connection.

During thermit welding, an all-metal connection is formed at the ends of the wires, the metal cross-section of which is greater than that of the connecting wires, and the electrical resistance is less than the cross-section of a whole wire of the same length.

The connection of stranded conductors by thermit welding does not change the electrical characteristics over time and therefore does not require additional working time for preventive tests.

However, welding joints must be performed only with high quality. Poor wire connections can be the result of sloppy wire preparation, use of non-standard pliers, under- or over-tightening, as well as one-way feed, jammed wires in the cartridge, etc.

As experience in wire welding shows, the most common causes of poor welding quality are jammed wires in the chuck and one-way wire feed. Connecting one of the wires in the chuck also results in one-way wire feed.

When welding wires on power lines, there were cases when, with the most careful preparation of wires and clamps, welding still did not work due to one-sided feeding of the wire to the cooling mold of the shrink chuck.

Carrying out thermit welding of wires

Thermite welding of wires is carried out using thermite cartridges (Fig. 1).

Thermite cartridge for welding aluminum and steel-aluminum wires consists of the following main elements:

-

a cooling form made of steel sheet with a thickness of 0.5 — 1.25 mm to protect the upper layer of the wire from burning and penetration of harmful impurities formed by the burning of the thermite mass in the welding zone,

-

aluminum insert for shaping the welding area and filling cavities,

-

a thermite block which, when burned, generates the necessary amount of heat to melt the cladding and the ends of the wires to be welded in the welding zone.

Thermite cartridge for welding copper wires consists of cooling made of copper or copper pipes with a thickness of 1.5-2 mm, an insert of copper-phosphorus alloy of the MF-3 brand and a thermite block.

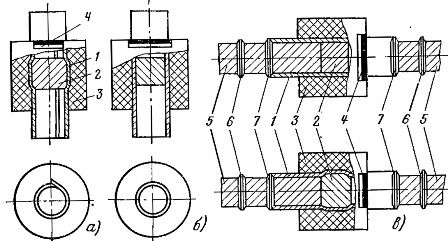

Rice. 1. Thermite cartridges: a — for aluminum and steel-aluminum wires, b — for copper and bronze wires, c — the position of thermite cartridges on the wires before welding, 1 — cooling form, 2 — insert, 3 — thermite muffle (checker) , labels with 4 places, 5 — wire, 6 — restrictive bandage, 7 — asbestos gasket.

The correct preparation of the ends of thermit welding wires is of great importance for a high-quality welding of the connection.The ends must be thoroughly cleaned of dirt, degreased with gasoline from grease and dried. Removing the grease from the ends of the wires and drying them is necessary, because when burning grease or gasoline, gases are formed that prevent the weld seam from filling with molten metal and contribute to the formation of voids and voids.

The ends of the welded wires are cut so that the cutting plane is flat and strictly perpendicular to the axis of the wire. Cladding wires with a cross section of up to 150 mm2 produces assembly scissors for cutting wires and wires with a cross section of more than 150 mm2 — using a hacksaw or a special device.

Most often, poor welding occurs due to one-sided feeding of the ends of the wire due to the fact that the metal of the insert first melts on one side and the ends of the wire rub or jam in the cooling mold.

In thermit welding of wires, it is necessary to monitor the feeding of the ends of the wires that will be welded from both ends of the cooling form. The metal in the weld zone remains in a liquid state for several minutes after the thermite mass burns and until the slag formed after the thermite mass burns cools to a dark color. For the same reason, you should not rush to loosen the pressure of the pliers and prematurely unscrew the knobs with the dies that secure the ends of the wires in the pliers.