Connecting wires and cables to the contact terminals of electrical equipment

The article discusses the device, purpose, techniques and methods of connecting aluminum and copper wires to the terminals of electrical equipment.

Construction norms and rules and "Instructions for finishing, connecting and branching aluminum and copper wires of insulated wires and cables and their connection to the contact terminals of electrical devices" provide for the connection of single-wire aluminum wires (section 2.5 — 10 mm2), bent into a ring , voltage of wires up to 2 kV and cables up to 35 kV and single-wire copper wires (section 0.75 — 10 mm2), bent into a ring, wires up to 2 kV and cables up to 1 kV. A method is used to connect single-wire aluminum and copper wires (with a cross section of 25 — 120 mm2), pre-twisted and crimped with a special device and crimping pliers.

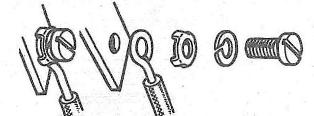

The connection of aluminum and copper wires to the contact terminals of various electrical devices and electrical devices is most often carried out using screw clamps.The core is bent into a ring and connected to the clamp. In this case, star washers of different sizes and other safety devices are used depending on the cross section of the wires.

The parts of the screw terminals must have a galvanized anti-corrosion coating. The wires must be thoroughly cleaned and lubricated with quartz-vaseline paste, and the connection must be tightly tightened.

In order to properly connect the wires and cables to the fixed contacts of the electrical equipment, you must have the following tools and devices: screwdriver 135 x 0.3 mm, side cutters, electrician's knife, universal electrical pliers and round-nose pliers, a tool for removing the isolation.

In order to properly connect the wires and cables to the fixed contacts of the electrical equipment, you must have the following tools and devices: screwdriver 135 x 0.3 mm, side cutters, electrician's knife, universal electrical pliers and round-nose pliers, a tool for removing the isolation.

Materials — quartz-vaseline paste, star washers, shaped washers or other devices, spring washers, M4 — M8 screws, nuts, sandpaper or glass cloth, assembly wires and cables.

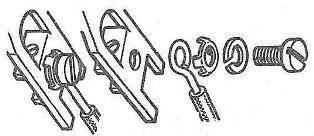

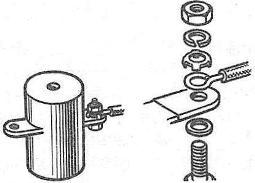

The standard way of connecting aluminum conductors of wires and cables with a cross section of 2.5 — 10 mm2 to the screw contact terminals of electrical equipment is shown in the figure.

When connecting solid wires to screw terminals, observe the following rules. Screw terminals shall have a star washer or other anti-extrusion device, a standard split spring washer, and anti-corrosion electroplating.

To clean the veins, use quartz-vaseline paste (50% by weight of quartz sand or ground quartz and 50% technical petroleum jelly without acids and bases) or technical neutral petroleum jelly and glass skin or sandpaper.

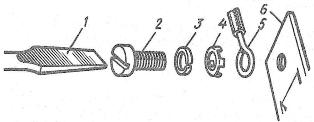

Core connection: 1 — screwdriver, 2 — screw, 3 — split spring washer, 4 — core bent into a ring, 5 — electrical contact, 6 — pin

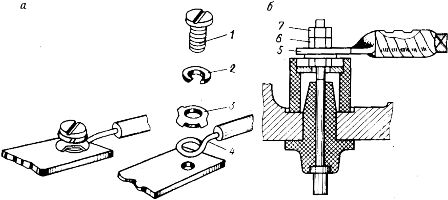

Connecting cores of cables and wires with a cross section of up to 16 mm (a) and more to the terminals of electrical equipment: 1 — pin screw, 2 — spring washer, 3 — star washer, 4 — wire bent into a ring, 5 — tip , 6 — copper nut, 7 — steel nut

Connecting cores of cables and wires with a cross section of up to 16 mm (a) and more to the terminals of electrical equipment: 1 — pin screw, 2 — spring washer, 3 — star washer, 4 — wire bent into a ring, 5 — tip , 6 — copper nut, 7 — steel nut

Connecting the wire to the screw clamp

First you need to determine the cross section of the connected core. Choose a screw, nut, star washer, spring washer depending on the cross-section of the wire to be connected. If the wire is connected to the output of the glucometer or other device (electrical equipment), check the correspondence of the dimensions of the clamp and the cross-section of the selected conductor.

Connecting the wire to the coil terminal

First, it is necessary to remove the insulation from the end of the connected core at a distance sufficient to bend the ring under the screw plus 2-3 mm with special pliers or a utility knife. Then you need to clean the bare end of the vein with a glass cloth under a layer of quartz-vaseline paste. You can then connect the wire to the coil terminal of the electrical device as shown in the example in the figure.

Connecting the wire to the output of the glucometer

It is necessary to bend the prepared end of the core into a ring with special pliers or round nose pliers. Position the core so that the bend in the ring is clockwise. Next, you need to install the parts of the screw bracket in the sequence shown in the figures.Push the ring onto the terminal through the star washer and spring washer, tightening the screw or nut securely with a screwdriver or pliers.