Heat shrinkable sleeves — a new way to connect and terminate cables

Reliable protection against the penetration of moisture and dirt, as well as the preparation of the workplace, are important for the quality of the installation of connectors. When installing connectors outdoors in any conditions and indoors in cases where moisture, dust and dirt can get into the connectors during installation, they are installed in a canvas tent.

Reliable protection against the penetration of moisture and dirt, as well as the preparation of the workplace, are important for the quality of the installation of connectors. When installing connectors outdoors in any conditions and indoors in cases where moisture, dust and dirt can get into the connectors during installation, they are installed in a canvas tent.

In order to reduce the impact on the quality of connectors of the above factors and improve the quality of the connection, new materials and structures are developed and applied.

In recent years, heat-shrinkable materials obtained from conventional thermoplastics (mainly polyolefins) through their radiation, radiation-chemical, chemical and other processing have become widespread in the world installation practice.

In the processing process, the linear structure of the molecules is cross-linked with the formation of elastic cross-links between them.As a result, the polymer acquires improved mechanical characteristics, increased thermal and atmospheric and corrosion resistance, resistance to cold flow and melting.

The main advantage of heat-shrinkable materials Shape memory, that is, the ability of products made of heat-shrinkable materials, pre-stretched in a heated state and cooled to ambient temperature, to maintain a stretched shape almost indefinitely and return to its original shape when reheated to 120-150 °C. This property allows not to limit the tolerances during assembly, which greatly simplifies the assembly and assembly works and reduces their labor intensity.

Sealing and sealing products have an inner sub-layer that melts when the stretched product is heated (shrinkage) and is pressed into all the irregularities of the product being sealed by the force of shrinkage. Upon cooling, the sealing sublayer hardens, resulting in reliable adhesion and sealing of the products.

Currently, technology has been developed to design and manufacture the most intricately shaped heat shrink adapter product with two or more taps designed to insulate and seal the backbone of cutting power cables with paper-impregnated insulation. Various heat-shrinkable tubes and cuffs are also used during installation, which facilitates and simplifies the installation of connectors.

The wide range of heat-shrinkable individual parts allows the use of one standard joint size for several types of cables and wire cross-sections, which in turn significantly reduces the need for spare joints that are in stock.

Heat-shrink products for cable fittings are developed and manufactured by Termofit JSC, St. Petersburg. The enterprise produces types of connectors: connection, final internal installation, final external installation.

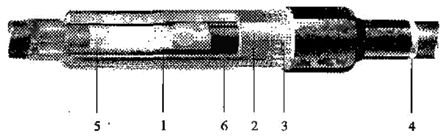

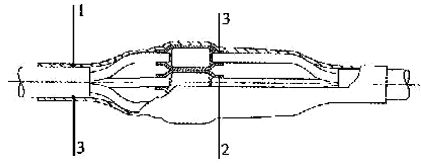

Connectors type STp (Fig. 1) heat-shrinkable are designed to connect power cables with impregnated paper insulation for voltages of 1, 6 and 10 kV when laid in the ground and in the air. The connectors are characterized by a high degree of hermeticity and technological assembly.

Semiconducting mastic tape is used to equalize the electric field at voltages of 6 and 10 kV. The set includes heat-shrinkable gloves, three-four fingers, tubes, cuffs, hose. The gloves and cuffs are equipped with sealing glue.

Hot melt adhesive can change its state depending on the temperature. At the operating temperatures of the cable fittings, the adhesive is in a solid state, and at shrinking temperatures it becomes a viscous state. The hot melt adhesive is applied to the inner surface of the sealing products in the factory by hot pneumatic spraying. When using heat shrinkable products, it eliminates the need for installers to roll connectors.

Heat shrinkable connectors have the following standard sizes:

-

three-wire up to 1 kV for cross-sections of cables 16-70 mm2 and 95-240 mm2;

-

four-wire up to 1 kV for cross-sections 16-70 mm2 and 95-185 mm2,

-

three-wire for 10 kV for cross sections: 16-70 mm2, 95-150 mm2, 150-240 mm2.

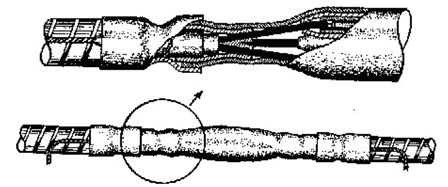

Heat-shrinkable end connectors, type KVTp (Fig. 2) indoor installations are intended for termination in dry, wet and damp rooms of power cables with impregnated paper insulation. Kit includes glove, tube and cuffs.The glove and cuffs are equipped with a sealing pad. Standard dimensions for cable cross-sections are the same as for connectors.

Fig. 1. Heat-shrink joint type STp

Rice. 2. Heat-shrink end sleeve for internal installation, type KVTp

The technology of installing the KVTP termination involves cutting the cable according to the usual technology and shrinking the heat-shrinkable parts using hand tools: a gas heater (based on a standard gas burner) or an air heater-electric fan. The installation time (not counting the cutting of the cable and fixing the ears) is 15-20 minutes, it depends on the length of the cut and does not depend on the type of cable and its cross-section. KVTp end fittings are recommended for use on cables up to 10 kV.

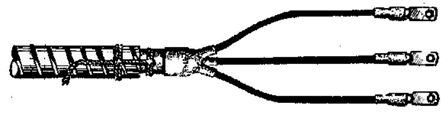

Heat-shrink end sleeves for external installation of the KNTp type (Fig. 3) are intended for the external connection of power cables with impregnated paper insulation. Environmentally resistant heat shrinkable insulators are used to interrupt leakage currents.

Insulators, gloves and cuffs are equipped with a sealing pad. When heat-shrinkable cuffs and gloves are heated, the sealing layer melts and spreads, providing a sleeve seal. The standard dimensions of the connectors for the cross-sections of the cables are the same as for the connectors.

MP «UlGES» together with CJSC «Poisk» has developed projects connecting heat-shrinkable sleeves of the CCt type, a distinctive feature of which is the method of «cold» technology for mounting the sleeve on the cable, which excludes soldering and welding operations, which require high qualification of the cable operator.

Couplers are used as a connecting device for high voltage cables (6-10 kV). They can be used on cables up to 1 kV. The sleeve has several versions corresponding to different cable cross-sections — 70, 95, 120, 150, 185 and 240 mm2. The variants differ in the dimensions of the sealing units, while the outer dimension of the coupling remains unchanged.

The body of the connector is a steel tube with a wall thickness of 4 mm. The cable entry points are sealed with spring-loaded oil-resistant rubber gaskets, which ensure the tightness of the bushings during dynamic shocks with short-circuit currents and mechanical influences.

The additional fastening of the cable to the connector body by castings ensures excellent mechanical strength of the connection in tension and bending. The metal sheaths of the cable are connected through the body by means of lead cuffs, with great effort pressed against the sheaths of the cable and the body of the connector with spring-loaded rubber seals.

To protect against corrosion, a polymer coating is applied to the outer surface of the clutch housing and cast brackets. In addition, to protect against corrosion during transportation and storage, a layer of grease is applied to the inner surface of the housing.

The inner volume of the coupling is filled with cable oil. It is possible to fill the joint with a bituminous compound or other substance whose insulating properties meet the requirements of the technical specifications for this joint.

Fig. 3. Heat-shrink end sleeve for external installation, type KNTp

Restoration of the core insulation is done using ceramic tube insulators.It is possible to use paper rolls, heat shrink tubes and other known methods. The cable cores are connected by means of special connecting sleeves equipped with self-tearing head bolts. A crimp connection is possible.

Joint-stock company "Transenerga" offers heat-shrinkable cable sleeves for voltage from 1 to 35 kV, manufactured by the German company Reichem. All of the company's cable accessories are based on cross-linked polymer technology with shape memory plastic. These polymers have improved mechanical properties, chemical and thermal resistance.

A wide range of heat-shrinkability of individual parts allows the use of one standard joint size for several types of cables and wire cross-sections. Reichem connectors during storage they practically do not age and can be stored indefinitely.

Product groups in the power industry include connectors, transition connectors, external and internal terminals. All cable accessories above 1 kV have a system for leveling the electric field strength, which can be made in the form of separate elements or already applied to the inner surface of the insulating tube.

At the ends, the outer tubes are resistant to surface erosion and tracking and provide a seal to the cable lugs. The connection area of the cable cores is closed with a double-layer heat-shrinkable tube, which ensures a gap-free surface connection of the inner insulating layer and the outer conductive layer.

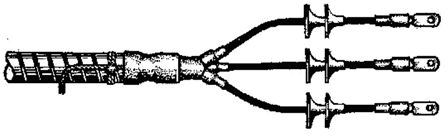

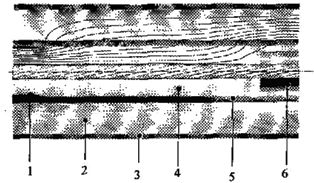

The Reichem Low Voltage Splicing System is a highly reliable and easy-to-install method of splicing traditional and modern cable types. The cable is cut according to the instructions.Small inner tubes and a large inner tube are placed over the cable and its conductors (Fig. 4).

The inner tube sits above the connector and (once the strands are connected) shrinks from heat, tightly adhering to the connector and wire insulation and providing the same wall thickness even in an uneven area such as a bolted connector. A layer of adhesive applied to the inner surface of the tube melts and expands when it shrinks, providing the connector with a seal and corrosion protection, and the cable allows it to expand and contract when exposed to heat.

The outer tube is located above the coupling and shrinks. The thick-walled tube performs the mechanical sealing function of the outer casing. The hot melt adhesive is applied to the entire inner surface, which creates a strong and reliable seal. After the assembly is completed, the coupling can be put into operation immediately.

Rice. 4. Low-voltage joint from Raychem: 1 — outer tube (thick wall protects against mechanical stress, and due to adhesion to the outer sheath of the cable provides sealing); 2 — inner tube: the thick walls of the tubes and hot melt glue provide electrical insulation and protect the connection area from moisture inside the cable; 3 — hot melt glue

Rice. 5. Connecting connecting company Raychem for medium voltage (up to 35 kV)

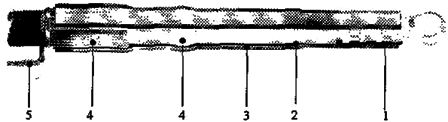

The design of Raychem connectors for medium voltage (up to 35 kV) is shown in fig. 6.

The numbers show the following:

1. The electric field strength distribution tube allows you to smooth out the jumps in the electric field strength in the area of connectors and in the cuts of the screen.When you install the tube, it shrinks and, compressing, distributes a special gap filler (5) around the connector and the edge of the screen. Cone insulation around connectors is not required.

2. Insulation and shielding. The internal rubber polymer (6) provides the necessary insulation thickness. The outer layer is made of a conductive, heat-shrinkable polymer. This layer restores the screen. Installing such a double-layer pipe saves time and ensures a strong connection between the insulating and shielding surfaces.

3. Metal braid. The copper mesh around the connection area restores the electrical shield of the corresponding cross-section and makes the connection to the outer shield of the connector.

4. External sealing and protection. As the outer tube shrinks, the glue applied to its inner surface melts; spreading evenly over the surface of the outer shell, the adhesives will create a barrier to the penetration of moisture and prevent corrosion, the outer tube provides the connector with protection against mechanical stress and chemical resistance. For cable armored cables, splicing kits include anodized steel frames or steel mesh.

This is a connector sleeve for single core cable with plastic insulation. The same principles apply to the 3-core cable. In transition joints (to connect cables with impregnated paper insulation to cables with plastic insulation) special oil-resistant tubes are used to transform cable with paper-oil insulation (flowing and non-flowing) and cable with plastic insulation with radial electric field distribution inside it (Fig. 6).

Rice. 6.Distribution of electric field strength in connectors: 1 — insulating screen; 2 — connector insulation; 3 — clutch shield; 4 — wire insulation; 5 — tube for leveling the voltage of the electric saw; 6 — connector

Reichem has created a system of internal and external cable terminals with paper or plastic insulation for single-core and three-core cables, with round or sector cross-section of the core for most types of cable armor and shields for voltages up to 35 kV. The main components of terminations up to 35 kV are shown in fig. 7.

Rice. 7. End connection of the company Raychem for medium voltage (up to 35 kV).

The numbers show the following:

1. Reliable sealing is achieved using special adhesive and mastic seals located inside the weatherproof and tracking components of the coupling structure. Simultaneously with the heating of the heat-shrinkable tubes, the sealing materials melt and disperse. For three-core cables, a heat-shrinkable glove with glue applied to its inner surface is used. This creates a weather and tracking resistant surface that is completely sealed from the inside, from the lug to the cable's outer sheath.

2. Equalization of the electric field strength using a material with set electrical parameters. This material is applied to the inner surface of the heat shrink tube. When the pipe shrinks, the inner layer is softened and compressed by the pipe, so voids cannot form even on the uneven surface of the insulation layer.

3. The tracking insulation pipes are resistant to surface electric discharges even in the harshest climates.

4.Filling filler with non-linear dielectric properties and can be easily applied to the desired place in the mold with a peel of adhesive tape. It ensures the elimination of the formation of air bubbles, which can cause discharges in the area of increased density of the electric field, at the cut of the screen.

5. Grounding. The ground wire or braid is embedded in the sealing compound to provide corrosion protection. For cables with ribbon shield or metal sheath with armor, a solderless welding system is supplied in the kit.

Reichem's shrinkable products have a number of advantages. The design of the products is suitable for different types and sizes of cables from different manufacturers, allows possible deviations in the separation of cables under operating conditions and provides a universal approach when installing different types of cables.

A full range of materials with factory-tested insulation ensures easy and quick installation. Heat shrink allows independence from cable manufacturing tolerances and will make it possible to install heat shrinkable products at low temperatures.

Equalizing the electric field strength with a tube, a layer of material, reduces partial discharge levels and increases operational reliability.