Installation of transformer substations and distribution devices

Indoor switchgear installation technology (switchgear)

KRU are installed only in premises where all construction work is completed.

Installation structures for distribution devices are made of corners or channels that are installed horizontally, adjusting to the level. An unevenness of 1 mm per 1 m length and 5 mm along the entire length is allowed. According to PUE these structures are connected to the ground loop with a 40 x 4 mm steel strip in at least two places.

When installing switchgear cabinets in a room, the width of the passage for a single-row installation should be equal to the length of the extension trolley plus 0.8 m, for a two-row installation - the length of one trolley plus 1 m. The distance from the cabinets to the side walls is the most - a little 0.1 m.

Installation of KSO chambers and switchgear cabinets begins with the final chamber. The correctness of the installation of the camera horizontally and vertically is checked only after the next camera is installed.At the end of the installation, the cameras are screwed in, starting with the outer camera. Tighten the lower bolts first, then the upper bolts.

Using a string, check the straightness of the upper part of the chambers and, if necessary, adjust their position using steel shims. Moving in the cart, check the correct installation of the distribution cabinets. The movable parts of the cart and the fixed parts of the cabinet must match, and the position of the cart must be firmly fixed. Especially carefully check the operation of the curtains, which must be lowered and raised without distortions and jams, as well as the action of mechanical blocking.

Using a string, check the straightness of the upper part of the chambers and, if necessary, adjust their position using steel shims. Moving in the cart, check the correct installation of the distribution cabinets. The movable parts of the cart and the fixed parts of the cabinet must match, and the position of the cart must be firmly fixed. Especially carefully check the operation of the curtains, which must be lowered and raised without distortions and jams, as well as the action of mechanical blocking.

The tested cabinets for switchgear and KSO chambers are finally fixed by electric welding to the mounting structure in four corners. Which also provides reliable grounding cabinets and cameras. Then they do the installation tiresobserving the colors of the phases. To do this, the outer sheets must be removed from the rail compartment of the cabinet. The branch rods are connected to the collection bolts.

Devices and devices removed during transportation are installed after installing the tires and connecting them to the primary and secondary circuits according to the scheme.

Devices and devices removed during transportation are installed after installing the tires and connecting them to the primary and secondary circuits according to the scheme.

The surfaces of the busbars at the contact points are washed and lubricated with petroleum jelly. These surfaces should not be cleaned with a file or sandpaper, because at the factory these places are coated with a special alloy of tin and zinc against corrosion. After installing the rails of the entire section, tighten the bolts of all contact connections. Check operation of switches, disconnectors, auxiliary contacts and interlocks.

The knives of the disconnector in the KSO chambers, when turned on, must enter the fixed contacts smoothly, without distortions at a depth of 30 mm and not reach the limiter by 3 — 5 mm. The disconnector drive must be automatically locked in the end positions with a lock.

The VMP-10 switches, after being mounted on supporting structures, are located vertically and along the axes of the camera, avoiding distortions.

Switch actuators are normally supplied to the installer in an assembled and adjusted condition. Adjustment of the drive together with the switch is carried out according to the factory instructions.

After connecting the output and supply cables and conductors of the secondary switching circuits, all metal structures of the switchgear (KSO) are connected to the grounding network. Grounding is done by welding the frames of the cameras in two places to the ground line.

Complete outdoor switchgear (KRUN) used for substation switchgear power systems, as well as as part of a package transformer substation 35 / 6-10 kV. They consist of separate cabinets.

Cabinets with built-in equipment and a control corridor. The back wall of the cabinets and the side walls are both the walls of the room. The front of the cabinets is designed similarly to the front of the internal distribution cabinets.

KRUN assembly technology

All foundation work for KRUN must be completed before installation can begin. The foundation is checked for compliance with the project drawings.Particular attention should be paid to the correct execution of the built-in channel bases for KRUN cabinets and the reliability of their attachment to the foundation racks.

Built-in foundations for KRUN are made of straight channels No. 12. The bearing surface is made in one plane, connected to the grounding loop in at least two places with strip steel with a section of 40 x 4 mm.

KRUN cabinets are delivered packed to the installation site. Before installing the KRUN cabinets, they are removed from the container pallets, the trolleys are rolled out of the KRUN body and the bodies are installed according to their arrangement in the switchgear.

KRUN cabinets are delivered packed to the installation site. Before installing the KRUN cabinets, they are removed from the container pallets, the trolleys are rolled out of the KRUN body and the bodies are installed according to their arrangement in the switchgear.

KRUN installation starts from the outer cabinet. Only after checking the correctness of the installation of the installed cabinet, proceed to the installation of the next one. Connecting the housings of KRUN cabinets on their side walls for sealing, insert a rubber tube pre-lubricated with glue. The control corridor roof is installed and connected to the end, front and rear walls of the switchgear. The next pair of front wall and roof elements is assembled in the same way.

Next, the following elements are installed on the front wall and roof of the switchgear. On the side of the still unfinished second end wall of the switchgear, the busbars are laid, they are fixed on the busbar holders, to which the spikes are connected. Then install the busbar compensators, compartment partitions, TSN, attach the busbar to it, fix the rear walls of the switchgear cabinets, assemble and fix the second end wall.

The housings of KRUN cabinets must not have vibrations and distortions.When rolling the stroller into the cabinet, the stroller should not distort in any position in the body, ie. when moving the cart, its wheels must rest on the guides.

The brackets are fixed on the roof of the cabinets for the installation of air outlets or inlets. They are delivered disassembled together with KRUN cabinets. After that, the input bus, the output line is installed, communication is carried out from the input cabinet to the TSN cabinet. In the control corridor, hinged cabinets of secondary circuits, power supplies for switching solenoids and operating current supplies, as well as lighting switches are installed. Installation of lighting.

Power cables are installed through a rear door in the back of the cabinet. Since the bottom of the KRUN cabinets is metal, the necessary number of holes for the passage of the cable are cut in it. After laying the power cable, this opening is sealed to protect it from moisture, snow, dust. The installation of secondary circuits between KRUN cabinets is reduced to the connection of plug connectors. After that, the operating buses and power buses are connected, the wires of the control cables of the external connections are connected.

Indoor transformer substation

A complete indoor installation of transformer substations (KTP) consists of three-phase step-down transformers, the highest voltage of which is 6 or 10 kV and the lowest voltage is 0.4 kV, and switchgear cabinets. Distribution cabinets are manufactured as sectional, linear and walk-in. They consist of bus and switching parts separated by partitions.

Switchgear cabinets (RU) with a voltage of up to 1 kV contain switching and protection equipment: withdrawable universal circuit breakers, ATS relay equipment, measuring devices, as well as measuring current transformers.

Control, protection and signaling circuits for KTP equipment performing AC work. The substations have one or two transformers with a capacity of 250, 400, 630, 1000, 1600 and 2500 kVA, which are supplied filled with transformer oil with a nitrogen blanket or with an oil conservator, as well as dry with fiberglass insulation. KTP with transformers filled with transformer oil can only be used when there are oil collection pits under them and the distance between two KTP is at least 10 m.

Complete transformer substations are equipped with alarm cabinets for warning. Depending on the order, the distribution cabinets are equipped with different schemes.

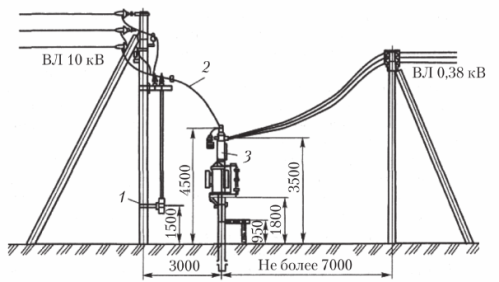

Placement and connection of the KTP to the overhead line with a voltage of 10 and 0.38 kV: 1 — drive of the disconnector; 2 — wire for voltage 10 kV; 3 — KTP

Installation of entire transformer substations

When starting the assembly of a complete transformer substation for indoor installation, the axes of the substation are checked, the base markings for the support channels of the switchgear and transformer slides are checked, as well as the required dimensions of the building part.

Switchgear blocks are lifted with inventory slings that are attached to the brackets. If there are no brackets, then the switchgear blocks are mounted on the bases using rollers made of pieces of metal pipes.If the switchgear blocks do not have support channels, the number of rollers is increased by at least four per block.

Switchgear blocks are lifted with inventory slings that are attached to the brackets. If there are no brackets, then the switchgear blocks are mounted on the bases using rollers made of pieces of metal pipes.If the switchgear blocks do not have support channels, the number of rollers is increased by at least four per block.

Multi-unit switchgear is installed in stages. The blocks are installed one by one, after removing special plugs that cover the protruding ends of the tires. The mounting channels of the cabinets are connected by welding using strip steel jumpers with a cross section of 40 x 4 mm. after the blocks are installed, the ground rods are welded to the support channels.

The switchgears are connected to the transformer by a flexible jumper and enclosed in a sheet metal box which is supplied with the complete transformer substation. When connecting the transformer terminals, be aware that excessive bending forces when tightening the nuts may cause oil leakage. The rails are bolted together. The box is bolted to the transformer and input cabinet.

The switchgears are connected to the transformer by a flexible jumper and enclosed in a sheet metal box which is supplied with the complete transformer substation. When connecting the transformer terminals, be aware that excessive bending forces when tightening the nuts may cause oil leakage. The rails are bolted together. The box is bolted to the transformer and input cabinet.

At the end of the installation of the KTP units, they check the serviceability of the wiring of the devices, the reliability of fixing bolted connections, especially contact and grounding, the operation of mechanical blocking, the condition of insulators. The high and low voltage cables are then connected. For grounding the KTP channels are welded to the ground loop in two places.