Installation of rotary engines

The installation of asynchronous electric motors with a phase rotor is carried out in the same way as the installation of electric motors with a squirrel-cage rotor, but at the same time additional work is carried out on the installation of starting rheostats, checking the brushes and the mechanism of the lifting brush.

Installation of a starting rheostat

Before installing the starting rheostat, the reliability of the contacts of the individual terminals is checked by tightening the fastening nuts and checking the continuity of the integrity of all circuits. The insulation resistance value is then measured.

If the value of the insulation resistance is less than 1 MoM, the reason for its decrease is established by checking the integrity of the insulation parts and the lack of contact between the ends of the wires and the body. The reason for the decrease in the value of the insulation resistance can be the moisture of the insulation plate on which the fixed contacts are located, or the disruption of the insulation of the course of the moving contacts.If necessary, these insulating parts are dried in a drying cabinet or with the help of electric lamps.

The starting rheostat, prepared for installation, is installed in the place indicated in the project. For easier operation, the rheostats are located near the starting equipment and in such a way that it is possible to see how the rotation of the electric motor and the mechanism proceeds.

The distance from the floor or service platform to the handle of the rheostat is taken as 800 — 1000 mm. For better cooling, a gap of 50 — 100 mm is left between the rheostat and the floor, etc.

The rheostat housing is grounded. The oil-cooled rheostat is filled with transformer oil to the specified level. The dielectric strength of the filled oil is not standardized, but dry oil is usually used.

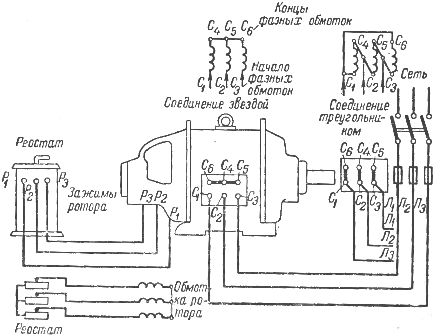

Scheme for connecting the windings and connecting an asynchronous electric motor with a phase rotor to the network

Scheme for connecting the windings and connecting an asynchronous electric motor with a phase rotor to the network

Checking slip rings and rotor winding

Before assembly (or when disassembling an electric motor with a phase rotor, if it is carried out), the condition of the rotor winding, its output ends, slip rings and brushes is checked. The reliability of the contacts to which the wire connects and the current wires to the brushes is checked, and the megohmmeter checks the insulation resistance and the integrity (without interruption) of the circuit.

The value of the insulation resistance of the windings and rings of the rotor should not be less than 0.5 Mohm. If the value of the insulation resistance is less than specified, the reason for its decrease is determined, the insulation resistance of the windings and each ring is checked separately.The reason for insulation degradation can be the humidity of the insulation of the windings or rings. In this case, the insulation is dried. Sometimes drying fails to improve the insulation condition of the rings due to insulation damage. In this case, the rings are removed and the causes that reduced the insulation resistance are removed.

The value of the insulation resistance of the windings and rings of the rotor should not be less than 0.5 Mohm. If the value of the insulation resistance is less than specified, the reason for its decrease is determined, the insulation resistance of the windings and each ring is checked separately.The reason for insulation degradation can be the humidity of the insulation of the windings or rings. In this case, the insulation is dried. Sometimes drying fails to improve the insulation condition of the rings due to insulation damage. In this case, the rings are removed and the causes that reduced the insulation resistance are removed.

Start of electric motors

Before starting wound-rotor electric motors, the inspection and start-up preparations are carried out in the same way as for squirrel-cage rotor electric motors. In addition to this, the condition of the starting rheostat, the brushes, the insulation resistance of the rotor winding and the wires or cables connecting the brushes to the starting rheostat, as well as the operation of the mechanism for shorting the rings and lifting the brushes is checked. After checking and eliminating the observed deficiencies, the electric motor is started, first at idle speed, and then under load.

Starting an electric motor with a wound rotor is carried out in the following sequence:

-

the handle of the starting rheostat is checked and placed in the «start» position until the rheostat is fully inserted (the motor is on the contacts corresponding to the greatest resistance),

-

checking the application of brushes on the rings and the «start» position of the mechanism for shorting the rings,

-

the starter of the stator circuit is turned on, and when the rotor of the electric motor is unfolded, the handle of the starting rheostat is slowly moved to the end position corresponding to the lowest resistance,

-

the operation of the brushes is checked, they should not spark much,

-

by turning the handle of the mechanism, the rings are short-circuited and the brushes are raised. If excessive warping occurs, wipe the rings with a clean, lint-free cloth or sand them with a glass cloth.

If arcing remains significant, the motor is stopped and the brushes are wiped while pulling strips of glass paper between the rings and brushes. With properly sharpened brushes, the entire surface fits snugly against the ring.

After each stop of the electric motor with a phase rotor, the handle of the starting rheostat is placed in the "start" position. When testing without load and under load, the direction of rotation, vibrations, heating of bearings and coils are checked.