Safety when installing electric motors

When loading and unloading electric motors, it is necessary to use working, reliable proven mechanisms and slings. Each inventory sling must have a label indicating the time of the inspection and the permissible load. Mechanisms used to install electric motors (cranes, winches, hoists, blocks).

The cable is attached to the electric motor to the holes (lifting rings) into which a steel rod or special eight hooks are inserted. Before the sling, it is necessary to check that the eyelets in the motor housing are securely screwed.

It is forbidden to stand under the lifted load and leave the lifted load unattended. Trained workers who are authorized to carry out these works are allowed to work on control mechanisms, as well as to transfer loads. Electricians who do not have the specified permits are prohibited from working on load slings and on lifting mechanisms.

Unloading and moving electric motors manually by two workers is allowed with a weight of no more than 80 kg.When loading and unloading electric motors manually from cars, etc., reliable platforms must be used. When moving electric motors in a horizontal plane, special trolleys must be used; in the case of manual movement, a wide board, wooden shield or frame is placed under the electric motor and moved on rollers made of steel pipe sections.

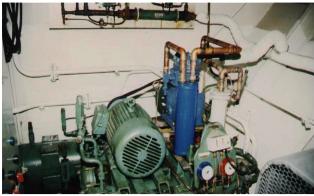

Installation of electric motors on foundations is carried out, as a rule, with the help of cranes. In the absence of cranes, electric motors can be installed on the base using hand winches, as well as hoists, blocks and other devices located above the place of installation of the electric motor, with a preliminary check of the possibility of loading these floors from the weight of the lifts electric motor.

Alignment of electric motors with a process machine must be done with the circuit breaker, switch off, and power line fuses removed with a placard prohibiting switch on; the ends of the wires or cables feeding the electric motor must be reliably shorted and grounded. The rotation of the rotor of the electric motor and the process machine must be coordinated with the workers working on the process machine.

Checking air gaps, changing bearing grease, adjusting and adjusting the brushes for a phase rotor electric motor and checking the insulation resistance of the windings should also be done with the circuit breaker turned off, the power line fuses removed with the switch prohibitive placard.

Disassembly and assembly of electric motors manually by two workers is allowed with the weight of rotors and side covers not exceeding 80 kg, taking precautions. Parts of disassembled electric motors (rotors, covers) must be placed on reliable wooden supports to prevent them from falling.

The removal of connecting half-couplings, rollers, gears and bearings by blows of hammers and hammers is prohibited; special choppers must be used for this purpose.

When washing bearings with kerosene and gasoline, as well as when covering coils with varnish, smoking and ignition are not allowed near the workplace.

During the drying of the electric motor with current, the housing must be grounded, and the power supply must be carried out in accordance with the rules and requirements of safety measures. When measuring the resistance and temperature of the windings, the electric motor must be disconnected from the power source.

Before testing the electric motor at idle speed and when loading after installation, it is necessary to: remove debris and foreign objects, check the presence and reliability of grounding, warn and remove workers from the process machine, put a fence on the coupling or belt drive.

Changing the direction of rotation of the electric motor (replacing the supply ends), as well as troubleshooting both electrical and mechanical parts of the device, must be done with the switch turned off, fuses removed with a prohibition poster hanging.

When installing electric motors, it is necessary to pay special attention to the good condition of the tool and not allow the use of tools that have defects, hammers and hammers must have handles of suitable length made of dried hardwood (dogwood, birch or beech), pine, spruce, aspen, etc. these types of wood should not be used as tool handles. Wooden handles of tools, hammers, hammers, files, screwdrivers must be processed smoothly (no knots, chips, cracks) and be firmly fixed in the tool.

Wrenches must be used to exactly match the size of the nuts or bolt heads. The use of spanners is recommended. When tightening nuts and bolts, do not place shims between the flats of the wrench and the nut. Chisels and cross cutters are allowed to be used with a length of at least 150 mm, their backs must not be knocked down.

When using step-down transformers for soldering and welding cable lugs, their power wiring must be reliably done, and the low voltage winding and the transformer body must be grounded.