Excavation of pits for supports during the installation of overhead lines

Excavation of overhead line support pits must be done mechanically. Cylindrical pits for single-column supports are excavated using special truck frames and self-propelled drilling and crane machines, and rectangular pits for anchor supports are dug with single-bucket excavators.

Excavation of overhead line support pits must be done mechanically. Cylindrical pits for single-column supports are excavated using special truck frames and self-propelled drilling and crane machines, and rectangular pits for anchor supports are dug with single-bucket excavators.

Excavation of support pits manually can be allowed with a small amount of earthworks and if it is impossible to use suitable mechanisms due to the narrow conditions along the route of the overhead line, the possibility of damage from working mechanisms to nearby objects (underground communications, earth structures, etc. .) or risk of injury …

Works on construction of overhead power lines it is advisable to organize so that as soon as the pits are ready, supports are immediately installed in them. Combining the work of digging pits and installing supports in them will allow the minimum time to leave the pits open and thus avoid accidents to people and animals, as well as spillage of the walls and accumulation of moisture at the bottom of the pits.

The pits are drilled with a truck in several stages. Having deepened the drill by 0.4 — 0.5 m, it is lifted along with the soil on it and, increasing the number of rotations of the drill, the soil is spread. After that, the drill is again lowered into the pit and deepened by another 0.4 — 0.5 m. These operations continue until a pit of the required depth and width is dug.

The depth of the foundation pits for the supports is determined by the project, depending on the nature of the soil, support heights and its purpose, the climatic conditions of the area, the number of wires placed on the support and their general cross-section, special conditions along the route, etc. The outer limits of pits on the earth's surface are determined by the angle of repose. The area of the foundation pit should allow movement of the butt of the support by 10 - 15 cm across the axis of the track for more accurate mounting of the supports in line alignment.

Pits for corner and end supports are dug so that the untouched wall of the pit is on the side of the tension of the overhead line wires.

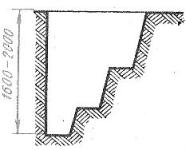

On sections of the route with steep slopes subject to erosion by water flowing down the slope, the pits are made manually, while the longitudinal axis of the pit for the support should be located perpendicular to the direction of the slope, and the pit for installing the support bracket (the transverse beam) should be perpendicular to the development of the pit. The pit developed by hand is made with ledges, which makes it easy to dig a pit and install a support in it.

Ready-made foundation pit for intermediate support with one column

When installing overhead line supports on sections of the route inundated by flood waters where soil erosion is possible, the supports should be strengthened by adding earth and arranging a blind area of cobblestone around the support.

Manual soil excavation is done using a hand drill, bucket shovel, sapper shovel, crowbar, ice pick and other tools. When the depth of the pit is more than 2 m and digging a pit in water-saturated soils, as well as if it is necessary to stay in the pit for a long time, the walls of the pit must have fasteners made of solid boards with a thickness of at least 25 mm and spacers with a diameter of at least 100 mm.

In winter, it is necessary to dig pits and place supports in them as soon as possible to avoid freezing of the bottom of the pit, which can subsequently lead to thawing and collapse of the soil under the support and lowering of the support, and in resulting in a violation of the size of the wires.

At an ambient temperature below 0 ° C, in order to avoid freezing, the pits are dug to a depth less than the design mark by 15 — 20 cm. The previously unselected layer of soil is removed from the bottom of the trench immediately before the installation of supports.

Trenches must be dug at the place of installation of the supports, taking precautions, especially after reaching a depth of 0.4 m, due to the risk of damage to communications or structures in the ground. If underground cable and pipelines are discovered during the excavation of the pit, or if gas is smelled, stop the work immediately and report it to the job supervisor for further instructions.