Laying of wire in steel pipes

Laying open and hidden electrical wires in steel pipes requires the cost of scarce materials and labor-intensive installation. Therefore, they are used to protect the wires from mechanical damage, as well as to protect the insulation and the wires themselves from destruction by corrosive vapors and gases, moisture, dust and explosive-fire mixtures from entering the environment of the pipe.

Connections and connections of pipes to boxes, devices and electrical receivers are performed without a special seal (when used to protect wires from mechanical damage), sealed (to protect pipes from dust, moisture, corrosive vapors and gases) and explosion-proof, for to exclude the possibility of explosive mixtures entering pipes, devices and electrical receivers.

Applicable to electrical wiring, steel pipes are divided into three groups: ordinary water and gas pipes, light and thin-walled electric welded pipes.

Before installation, the inner surface of the pipes is cleaned of scale and unevenness, and the inner and outer surfaces are painted with asphalt varnish.Pipes in concrete, do not paint outside for better adhesion to concrete. Galvanized pipes are laid without painting. During the installation, the normalized values of the angles and bending radii of the pipes are observed depending on the diameter of the pipes, the number and section of the wires laid in them. Ordinary pipes for water and gas are used only in explosive installations; light — in justified (from the point of view of saving metal) cases with open laying in dry and damp rooms; as well as for concealed installation in dry and wet rooms, ceilings, stepped floors, foundations and other building elements with sealing of entry points in boxes and connecting pipes with steel threaded connectors. Thin-walled electrowelded pipes are used for open laying in dry and wet rooms without sealing the joints and entering boxes.

Organizations for electrical installations use an industrial method for the installation of steel pipes... The supply of pipes, their processing, cleaning, painting, picking into separate units and packages is carried out at the Ministry of Education and Culture.

Installation of pipes in place placed in ready-made assemblies, connect them together and tighten the wires in them. The billet of pipe blocks in MES provides for the use of normalized elements in the form of corners with standard bending radii. Pipes are assembled in workshops either according to sketches or according to schemes imitating the location of electrical receivers to which pipes with wires are fed. Threaded connection They are made by sealing a drawbar on red lead or with a special fluoroplastic tape of the FUM brand.Such a connection is mandatory for ordinary and light water and gas pipes in explosive areas, humid, hot rooms, as well as in rooms containing vapors and gases that have a harmful effect on the insulation of the wires. In dry, dust-free rooms, it is permissible to connect steel pipes with sleeves or collars, without sealing.

Open-lay steel pipes fastened with brackets and clamps. It is prohibited to attach steel pipes of all types to metal structures using electric and gas welding. When laying steel pipes, certain distances between their attachment points must be observed: no more than 2.5 m for pipes with a nominal opening of 15 — 20 mm, 3 m — with a passage of 25 — 32 mm, no more than 4 m — with a passage of 40 — 80 mm, no more than 6 m — with a passage of 100 mm. The permissible distances between expansion boxes depend on the number of turns in the pipeline: with one — no more than 50 m; with two — no more than 40 m; on three — no more than 20 m. Selection of the diameter of the steel pipe for placing wires in it depends on their number and diameter of the wires.

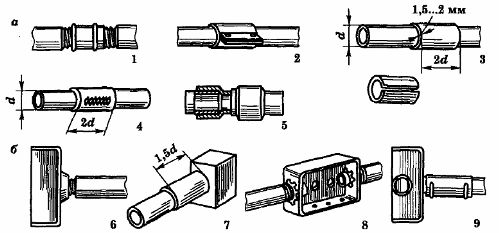

Connections and conductors of steel pipes in boxes: 1 — threaded sleeve, 2, 9 — screw sleeve, 3 — pipe section with welding on the ends, 4, 7 — welded sleeve, 5 — socket with socket, 6 — with thread in the box pipe , 8 — mounting grounding nuts on both sides.

In order to avoid damage to the insulation of the wires during stretching, plastic sleeves are installed at the ends of the steel pipes... To facilitate the withdrawal of wires, talc is blown into the pipes and a steel wire with a diameter of 1.5-3.5 is pre-tensioned mm, to the end of which a taffeta ribbon with a ball is attached.The ball is then blown into the tube with compressed air from a small mobile compressor at an excess pressure of 200-250 kPa, a wire is drawn with a taffeta tape, followed by a wire or cable attached to the wire.

For vertically laid pipes, it is recommended to tighten the wires from the bottom up. Connections and branches of wires laid in pipes, perform in boxes and boxes.