What are industrial controllers

The term «industrial controller» characterizes the class of industrial automation tools that are made in a special design, have a developed set of communication devices with the object and are necessarily programmed in languages of general application (not problem-oriented).

This means that the elementary CPU base can be anything from 8-bit single-chip to communication processors. Following the concept of open systems, manufacturers of industrial automation equipment (but not of telemechanics and communication technologies) have largely switched to the IBM PC-compatible component base. Therefore, in most cases, the definition «industrial controller» in a narrow sense hides a PC-compatible controller with a modular design, focused on solving local control problems with minimal implementation of human-machine interface functions. An industrial controller is most often a modular programmable controller for solving complex automatic control tasks.

There are two lines of hardware development for PC-compatible industrial controllers:

1.Maximum preservation of the IBM PC architecture in the field of small embedded systems. The most famous products of this line are modular controllers in the PC / 104 standard (the standard is proposed by "Ampro") and micro PC controllers produced by Octagon Systems.

Both standards are the least deviating from the original concept of personal computers. Both standards have a modular construction principle, where the final configuration of the product is determined by the set of functional boards (modules) included in its composition. Therefore, the products of the considered standards in different configurations can be equally well classified as industrial computers and industrial controllers.

Rice. 1. The central processor board of an industrial controller in the microcomputer standard (model 5066-586 from «Octagon Systems»)

2. Maximum preservation of PLC architecture and design solutions with the replacement of the processor module with PC compatible open source software. The motto of the products of this line is "all the advantages of PC and PLC in one product". Moreover, the leading manufacturing firms have approached this solution from different angles.

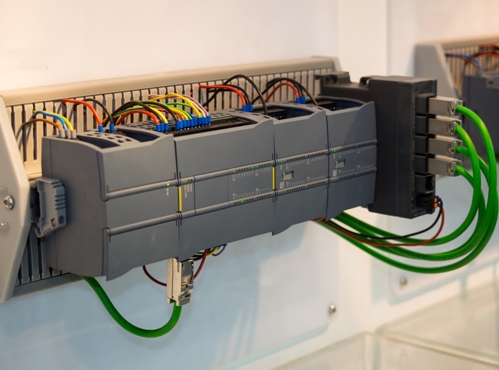

Thus, the legislators in the field of PLC from Siemens and Festo, based on ready-made Power-PLC solutions with a developed library of intelligent peripheral modules, proposed alternative solutions with a replacement of the central processor. The Siemens Simatic S7-400 wide-format PLC has a Simatic M7 counterpart with an FM456-4 processor.

Festo has added the PC-compatible processor FPC406 to the FPC400 PLC processor module set.In addition, it is allowed to work simultaneously within the FPC400 of the FPC405 PLC processor module, which is exclusively intended for the control functions of the technological process, and the FPC406 module, which is used for data storage and processing and visualization of the technological process.

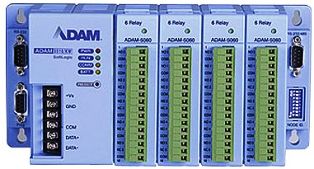

Similar solutions are offered by famous people PLC manufacturers already at the micro PLC level. An example of this is the Festo FEC PLC and the Direct Logic DL205 PLC. Approaching such a solution, the legislator of industrial computers Advantech proposed a series of ADAM5000 controllers, which in terms of the number of served discrete inputs / outputs correspond to a micro PLC, but have an open Processor architecture.

Rice. 2. PLC FEC FESTO

Rice. 3. PLC DirectLOGIC DL205

Rice. 4. Industrial controller ADAM5000

Russian manufacturers of industrial controllers are trying to find their niche among the wide range of tools offered by world-renowned manufacturers.