Bimetallic plate and its use in electrical engineering

A bimetallic plate is a plate specially made from a pair of dissimilar metals or from a bimetal. Such plates are traditionally used in thermomechanical sensors.

Bimetallic or mechanically connected two pieces of different metals with different degrees of thermal expansion have a rather interesting characteristic which is as follows.

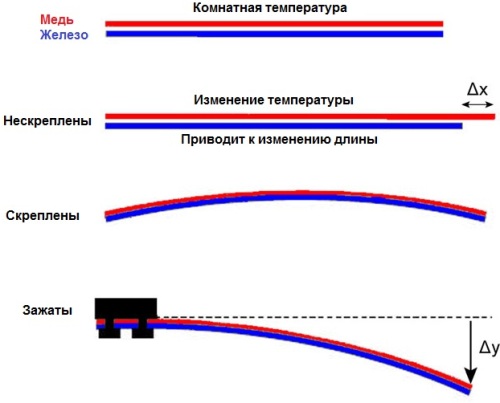

If a pair of identical plates, that is, made of the same metal and of the same dimensions, are subjected to heating, they will elongate to the same extent. But if the plates are made of different metals (say, one of copper and the other of iron), then when heated together, due to different thermal expansion, the plates will elongate in different ways.

Welded, welded or riveted two plates form one bimetallic plate. One end of such a plate is usually fixed statically in a stationary holder inside the device, and the other is free to move according to the current temperature of the plate as a whole.

Such plates for various purposes are usually made of brass and invar (invar is an alloy of nickel and iron).As a result of heating, the plate will bend towards the metal with less thermal expansion, and the free end of the plate will move as a result of deformation. The plates are effective in a very wide temperature range.

The use of bimetallic plates in electrical engineering

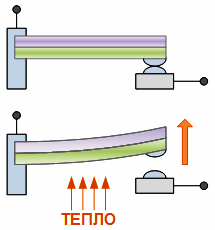

In fuses and thermostats, bimetallic plates control the condition of electrical contacts. The plate opens or closes the circuit heating element, cuts off the power supply to the boiler, etc.

In the simplest designs, the contacts are brought together and separated slowly, in more fanciful ones - by a few millimeters in a sharp jump (characteristic clicks can be heard from the iron during ironing or from a home heater set to a certain temperature).

In an electric kettle, the contacts of the bimetallic plate protect it from overheating and inside circuit breaker — wiring against exceeding the permissible current value.

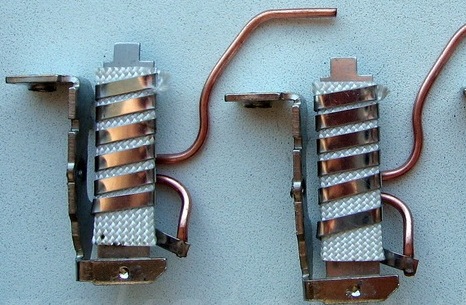

So-called thermal relays or circuit breakers that require manual reset after personnel clears the fault—a bimetallic plate here and there.

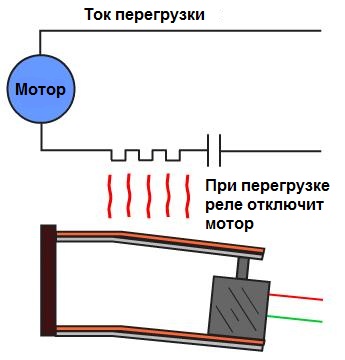

V starters for fluorescent lamps and in the control circuits of electric motors, bimetallic plates are used to switch the operating mode of the device after it is turned on. When the device is started, the plate starts and continues to heat up.

In this case, the bimetallic plates are equipped with a special heater and contact, there is a heating coil made of high-resistance wire, or the plate is heated directly by the current passed through it. This is how some protective relays and switching pulse generators work. If the motor overheats during operation, the relay will operate and disconnect the motor from the network.

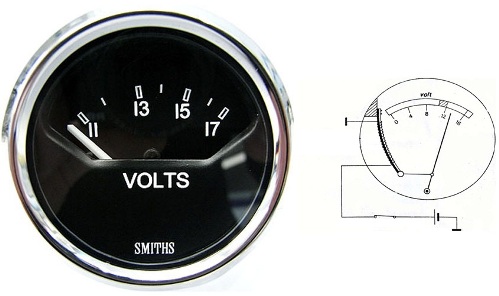

V Measuring tools, in fact — in bimetallic plate thermometers with a heater, this effect is also used. To get a voltmeter or ammeter, the plate is switched on in different ways.

Such a device energetically, of course, is greedy, but there are no mechanically rubbing parts in it, it is resistant to vibrations, resistant to pollution and recovers in case of moisture.

Measuring devices of this type, on bimetallic plates, are still used successfully in automotive electronics.