Varistors - principle of operation, types and application

A varistor is a semiconductor component that can change its active resistance non-linearly depending on the magnitude of the voltage applied to it. In fact, it is a resistor with such a current-voltage characteristic, the linear section of which is limited to a narrow range, to which the resistance of the varistor comes when a voltage above a certain threshold is applied to it.

At this point, the resistance of the element changes sharply by several orders of magnitude — it decreases from the initial tens of MΩ to units of Ohm. And the more the applied voltage increases, the smaller and smaller the resistance of the varistor becomes. This property makes the varistor a staple of modern surge protection devices.

Connected in parallel with the protected load, the varistor absorbs the disturbance current and dissipates it as heat. And at the end of this event, when the applied voltage decreases and returns above the threshold, the varistor restores its initial resistance and is again ready to perform a protective function.

We can say that the varistor is a semiconductor analogue of a gas spark gap, only in a varistor, unlike a gas spark, the initial high resistance is restored faster, there is practically no inertia, and the range of nominal voltages starts from 6 and reaches 1000 and more volts .

For this reason, varistors are widely used in protective circuits. semiconductor switches, in circuits with inductive elements (for extinguishing sparks), as well as independent elements of electrostatic protection of the input circuits of electronic devices.

The process of manufacturing a varistor consists of sintering a powdered semiconductor with a binder at a temperature of about 1700 ° C. Semiconductors such as zinc oxide or silicon carbide are used here. The binder can be water glass, clay, varnish or resin. On the disk-shaped element obtained by sintering, electrodes are applied by metallization to which the assembly wires of the component are soldered.

In addition to the traditional disc form, varistors can be found in the form of rods, beads and films. Adjustable varistors are made in the form of rods with a movable contact. Traditional semiconductor materials used in the manufacture of varistors based on silicon carbide with different bonds: thyrite, willite, lethine, silite.

The internal principle of operation of the varistor is that the edges of small semiconductor crystals inside the bonding mass are in contact with each other, forming conductive circuits. When a current of a certain magnitude passes through them, local overheating of the crystals occurs and the resistance of the circuits decreases. This phenomenon explains the CVC nonlinearity of the varistor.

One of the main parameters of the varistor, along with the rms response voltage, is the nonlinearity coefficient, which indicates the ratio of the static resistance to the dynamic resistance. For varistors based on zinc oxide, this parameter varies from 20 to 100. As for the temperature coefficient of resistance of the varistor (TCR), it is usually negative.

Varistors are compact, reliable and perform well in a wide range of operating temperatures. On printed circuit boards and in SPDs you can find small disk varistors with a diameter of 5 to 20 mm. To dissipate higher powers, block varistors with overall dimensions of 50, 120 and more millimeters are used, capable of dissipating kilojoules of energy in a pulse and passing currents of tens of thousands of amperes through them, while not losing efficiency.

One of the most important parameters of any varistor is the response time. Although the typical activation time of a varistor does not exceed 25 ns, and in some circuits this is sufficient, nevertheless in some places, for example, for protection against electrostatics, a faster response is required, no more than 1 ns.

In connection with this need, the world's leading manufacturers of varistors direct their efforts to increase their performance. One way to achieve this goal is to reduce the length (respectively, the inductance) of the terminals of the multilayer components. Such CN varistors have already taken a worthy place in the protection against static output of integrated circuits.

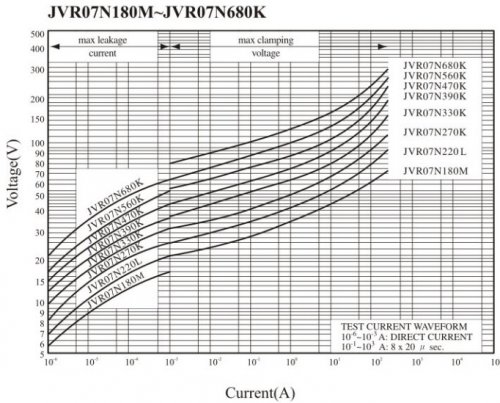

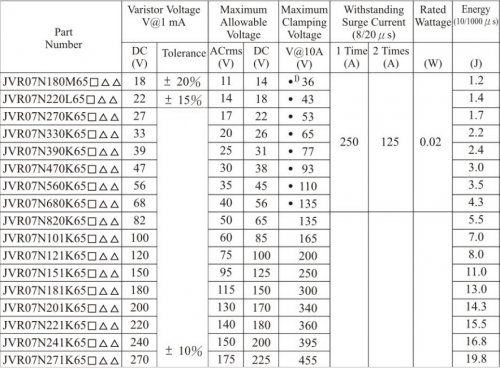

The DC varistor rating voltage (1mA) is a conditional parameter, at this voltage the current through the varistor does not exceed 1mA.The rated voltage is indicated on the marking of the varistor.

ACrms is the rms ac voltage response of the varistor. DC — DC voltage actuation.

In addition, the maximum allowable voltage at a given current is standardized, for example V @ 10A. W is the rated power dissipation of the component. J is the maximum energy of a single absorbed pulse, which determines the time during which the varistor will be able to dissipate the rated power while remaining in good condition. Ipp — the peak current of the varistor, normalized by the rise time and the duration of the absorbed pulse, the longer the pulse, the lower the permissible peak current (measured in kiloamperes).

To achieve greater power dissipation, parallel and series connection of varistors is allowed. When connected in parallel, it is important to choose varistors as close as possible to the parameters.