How to choose the brand and cross-section of the cable

The main rule when choosing is to buy goods only from well-known manufacturers. You should also pay attention to what metal the cable is made of. Aluminum cable is cheaper, but oxidizes quickly when exposed to air, has limited flexibility, and has less conductivity than copper cable. Copper cable is more expensive than aluminum, but without its disadvantages.

Also, when choosing, you have to decide cross section of the cable (more precisely, the cross-sectional area). The cross-section of the cable must be selected taking into account the future load of the network. It should be borne in mind that for aluminum wires you should choose a cross-section one step higher, since their conductivity is about 60% of the conductivity of a copper cable. Main types of sections: 0.75; 1; 1.5; 2.5; 4; 6; 10. The unit of measurement of the section is the square millimeter (mm2).

For residential premises, household wires PVS, VVG, VVGng, NYM are suitable. The latter type of cable contains an additional layer of melo-rubber insulation, which prevents the formation of cracks when used in adverse conditions.A more elastic compound is used as external insulation, which also increases safety. As a result, this cable is gaining more and more popularity.

For residential premises, household wires PVS, VVG, VVGng, NYM are suitable. The latter type of cable contains an additional layer of melo-rubber insulation, which prevents the formation of cracks when used in adverse conditions.A more elastic compound is used as external insulation, which also increases safety. As a result, this cable is gaining more and more popularity.

NYM cable designed for industrial and domestic fixed installations (open or hidden) of electrical circuits indoors and outdoors. Outdoor use is only possible without direct sunlight. It is possible to use the cable on, in and under plaster, in dry, damp and wet rooms, as well as in brickwork and in concrete, with the exception of direct pressing in vibratory filling and concrete stamping. In this case, the installation must be carried out in pipes, in closed installation channels.

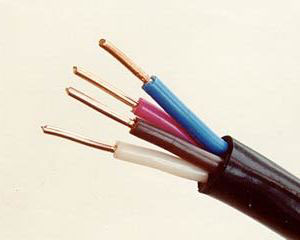

NYM cable construction

Core: solid copper wire

Insulation: Polyvinyl chloride (PVC) compound with a distinctive color:

-

2-core: black and blue

-

3-core: black, blue, yellow-green

-

4-core: black, blue, yellow-green, brown

-

5-wire: black, blue, yellow-green, brown and black with distinctive markings.

Intermediate shell: rubber filled with chalk

Outer sheath: light gray PVC compound that does not support combustion.

NYM cable uses an intermediate sheath made of chalk-filled rubber that:

-

allows you to easily and conveniently "bare" the cable during installation

-

increases the fire safety of the cable

-

increases cable flexibility

PVS It is a flexible, copper wire with twisted wires and a circular cross-section, intended for connecting household electrical appliances and power tools, equipment for small mechanization for gardening, microclimate devices to energy sources, as well as for the manufacture of extension cords. The installation is carried out at an ambient temperature of -15 ° C to + 40 ° C.The insulation and sheath are made of PVC compound. Conductor — annealed copper wire with increased flexibility.

VVG — power cable intended for the transmission and distribution of electrical energy in stationary installations for voltages of 0.66 and 1 kV at an ambient temperature of -50 ° C to +50 ° C at a relative humidity of up to 98% (at t up to +35 °C). VVG cables are designed for laying in dry and wet industrial premises, on special cable racks, in blocks.

Laying (installation) of this group of power cables is allowed (without preheating) at a temperature not lower than -15 ° C. Cables of this type must be laid with a bending radius of at least 6 cable diameters. Conductor: copper, single or stranded. Insulation — PVC compound. Sheath-PVC-joint (for cables with index «NG»-low-flammable PVC-joint). When laying this type of cables, it is necessary to ensure that the bending radius does not decrease below six diameters of the cross sections of the conductor.

VVG cable with the «NG» index differs from the standard only in that its sheath contains non-combustible materials, which is why it is successfully used to increase the level of electrical safety of an object.

The core of the VVGng cable is round, made of soft copper wire. With a cross-section of 16 mm2, it is multi-wired. The VVGng cable is used for laying in dry and wet industrial premises, on special cable racks, in blocks, as well as for laying outdoors. Cables are not recommended for buried ground (trenches).

The VVGng LS cable has a copper conductive core, single-wire or multi-wire, round or sector, class 1 or 2 according to GOST.The insulation of the VVGng-LS cable is made of a polyvinyl chloride compound with a reduced fire hazard. The insulated conductors of stranded cables have a distinctive color scheme. The insulation of the neutral wires is blue. Two-color (green-yellow) insulation of the ground wire. Twisting-twisted insulated conductors of two-, three-, four-core cables; two- and three-core cables have a core of the same section, four-core cables have all cores of the same section or one core of a smaller section (earthing core or neutral).

The cable VVGng-LS, without the spread of combustion, with low smoke and gas emissions, is intended for the transmission and distribution of electricity in stationary installations for a nominal alternating voltage of 660 V and 1000 V and a frequency of 50 Hz. Cables are manufactured for general industrial use and nuclear power plants for domestic supply and export.

It is recommended to purchase a cable or wire with a margin. Of course, in case of shortage, the cable can be extended, but the whole is always more reliable than assembled from pieces.

If you choose products with polyethylene insulation, then it is better to take wires with insulation from stabilized self-extinguishing polyethylene (in the wire brand it is indicated as Ps).

Wire section, mm

square

Copper insulator wires. Open Wiring:

current, A

Copper insulator wires. Hidden wiring:

current, A

Aluminum insulator wires. Open Wiring:

current, A

Aluminum insulator wires. Hidden wiring:

current, A

0,5

11

—

—

—

0,75

15

—

—

—

1

17

15

—

—

1,5

23

17

—

—

2,5

30

25

24

19

4

41

35

33

28

6

50

42

39

32

10

80

60

60

47