Why are we needed and what are power switching devices

The switching device performs the main function of controlling the electrical circuit: turning it on and off. This type of apparatus includes: knife switches, switches, disconnectors.

Switches are designed to turn electrical circuits on and off "live," that is, while an electric current is flowing through the circuit.

All electrical devices with moving parts can be divided into automatic and non-automatic. Automatic - these are devices that come into action from a given circuit mode, or machines, and non-automatic, the action of which depends only on the will of the operator.

Circuit breakers are low voltage (available for voltage up to 1000 V) and high voltage (for voltage above 1000 V).

The simplest non-automatic low voltage switch — switchconsisting mainly of a movable blade, a fixed contact and a handle.

The operator manually turns the switch on or off by rotating the blade to a vertical or horizontal position. The circuit breaker contacts are located in the air only.

A simple one-pole ruble switch

700 rubles at a historic hydroelectric plant in Germany

Fuses in indoor switchgear in China

With the increase in operating voltage and power, such a device can no longer meet the needs of work, and gradually more and more advanced types of switches appear.

In electrical installations for voltages up to 1000 V, they are most widely used air breakers of different designs.

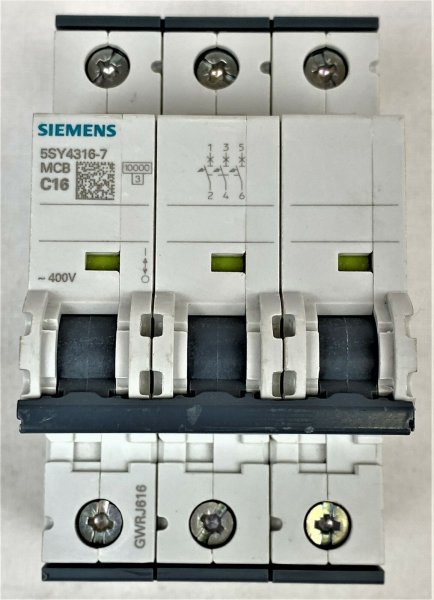

Siemens low-voltage circuit breaker for current 16A

Schneider Electric 125 A low voltage circuit breaker

Domestic circuit breakers in the electrical room (there is a 30-year gap between them)

When the circuit is de-energized between the deflecting contacts of the switch an electric arc occurs to be paid. For better arc extinguishing, special devices are used in the machines that improve the arc extinguishing process, the so-called arc extinguishing chambers different designs.

Closed switchgear electrical panel

For high voltage circuits, a simple air circuit breaker can no longer meet the operational requirements. The first thing that was done in the direction of improving the design of the switch was to lower the contacts in transformer oil, resulting in the so-called oil switch. Currently, the oil breaker is already a very complex device that uses many achievements of science and technology for its work.

Transformer Substation High Voltage Oil Breaker

The operation of the oil switch during shutdown is reduced to the following: due to the action of the high temperature of the arc, the oil decomposes into gases, the main component of which is hydrogen.Thus, the arc burns in a gas medium that is in a dynamic state, there is a violent mixing of ionized and non-ionized particles, cold and hot gas particles, and at one of the moments when the current passes through zero, due to the periodicity, the arc is extinguished.

Gas formation is very strong, significant pressure builds up in the switch and if the switch is not designed correctly, it can explode.

With oil circuit breakers with arc extinguishing chambers, arc extinguishing is more painless and quick. Here, the energy of the arc is used to create a pressure that greatly increases the movement of gas around the arc and thus contributes to extinguishing the arc.

There are many camera designs and the principles of their operation are quite different, but they all serve mainly one of two purposes:

- or create movement of oil and gas relative to the arc;

- or the arc is moved relative to the oil and the walls of special chambers.

For such switches, the drive is no longer a structural unit with the switch: in most cases, the drive is implemented structurally separately from the switch and is connected to the latter using special mechanisms.

There are also so many other types of high voltage circuit breakers that have long since replaced bulk oil circuit breakers. This, for example, small volume oil switches, in which porcelain tanks are used and therefore no special insulation of the contact parts of the tank is required and the amount of oil in them is much less.

Oil column switch for voltage 10 kV

Next should be mentioned «compressed air interrupters», where the arc is extinguished with a jet of compressed air. These switches have a number of advantages and are increasingly replacing oil switches. The drive for them also works from compressed air, but the drive control is electric.

Air circuit breaker for voltage 110 kV

Modern vacuum and SF6 circuit breakers are also used.

Vacuum breaker

Circuit breaker SF6

The design of modern keys is very diverse and you can read more about them here:Comparative characteristics of high voltage oil, SF6 and vacuum circuit breakers

Disconnectors are also a high-voltage switching device, but they are not designed to switch on and off while live (except in the cases of switching very low currents, specifically indicated for each type of disconnector).

High voltage disconnectoras a rule, it is built air, that is, with contacts that are simply in the air, since one of the main requirements for a disconnector is that its contacts are directly visible, so that it is possible to accurately determine whether the disconnector is on or off.

Disconnector

Essentially, a disconnector is an electrical device designed to connect (or disconnect) metal two sections of a circuit together when current cannot flow through those sections.

The design of the disconnector is very similar to the design of the knife switch, only its dimensions, corresponding to its high operating voltage, are much larger and the drive system is much more complex than that of the knife switch.

A number of other devices that perform on and off operations can be attributed to power switching equipment, for example load break switches, separators and short circuits, but the devices listed in this article are the most prominent representatives of switching equipment.

See also: What are they, how are low voltage switchgear arranged and how do they work