How the thermostat of an electric iron works and works

Everyone is familiar with an electric iron with a thermostat. This simple device contains all elements of the automatic regulator.

The object of adjustment is the metal base of the iron, which has a smooth outer surface (ironing surface), and the adjustable value is the temperature of the ironing surface.

Depending on the type of fabric, the temperature of the ironing surface must be maintained within certain limits. So, for ironing synthetic fabric, it is necessary that the temperature of the sole of the iron is 60 — 90 ° C, when ironing silk fabric — 100 — 130 ° C, and linen — 160 — 200 ° C.

The executive body of the thermostat is an electric heating element. When connected to the mains, it heats up and emits a certain amount of heat to the base (sole) of the iron, while the temperature of the latter rises.

If the heating element is turned off, the temperature of the iron's base decreases as the amount of heat from the fabric to be ironed is transferred to the surrounding air.This process acts as an external influence on the object of regulation.

The closing and opening of the circuit of the heating element is carried out by a pair of contacts connected in series to this circuit.

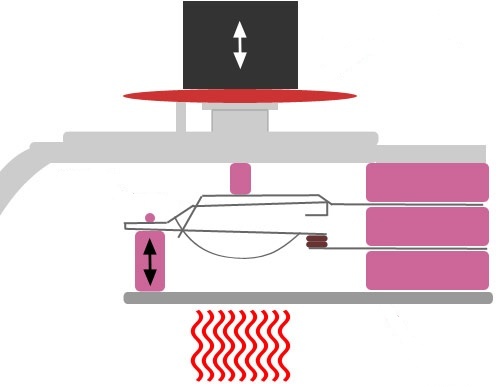

The temperature of the sole of the iron is monitored using a special sensor. Its action is based on use bimetallic plate, which consists of two different metal layers (for example, iron and aluminum, iron and copper).

It is known that different metals are heated differently. For example, with the same temperature rise for an iron and an aluminum plate of the same length, the elongation of the aluminum plate turns out to be twice the elongation of the iron plate.

When the bimetallic plate is heated, it bends toward the layer that expands less. In this case, the bending of the plate occurs the greater, the greater the change in temperature.

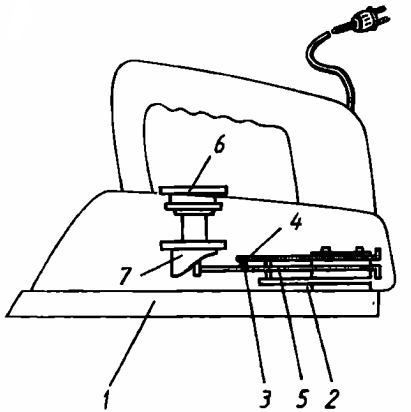

Iron device with automatic temperature regulator: (1 — iron sole; 2 — bimetallic plate; 3 — contact pair; 4 — upper contact plate; 5 — lower contact plate; 6 — disk — temperature setting; 7 — rotary wedge of setting )

In the iron thermostat, the end of the bimetallic plate 2 is attached to the sole 1, the latter controls the movable contact of the contact pair 3, which serves as a comparison body (zero body) of the thermostat.

As the temperature of the iron base increases, the bimetallic plate also heats up. At the same time, it bends and its free end begins to move. This movement is the information about the temperature change, which enters the zero body in the form of a certain movement of the upper contact.

When the iron cools, the plate bends in the opposite direction and the upper contact falls. When it comes into contact with the bottom contact, the heating element (the actuator) turns on and the temperature of the iron begins to rise. After a corresponding increase in temperature, the upper contact rises again and the circuit of the heating element opens. The iron will start to cool again.

The device and principle of operation of the electric thermostat for iron

The temperature of the sole of the iron fluctuates between the upper and lower values, so here we can talk about maintaining a certain average temperature, the value of which is set by moving the lower contact up or down, which is done by turning the dial in the dial.

The lower contact is attached to the free end of the flat spring. A rotating wedge attached to the disc rests against it. When the dial is turned to one side or the other, the bottom contact moves up or down.

The higher the lower contact, the higher the average temperature maintained by the regulator. In this way, by turning the dial of the dial, information is entered into the zero body about what the temperature of the iron base should be.

Thermostat for electric iron

In the example under consideration, there are all elements of the automatic control system, except for the amplifier, which in this case is not necessary, since the signal of the comparator (closing or opening the contact pair) is sufficient to turn on or off the actuator (heating element).

Such a regulator is also used in a household electric oil cooler, where it serves to maintain a given average surface temperature, as well as in some other household and industrial installations.