Elements of a home electrical network. Conductors. Cords. Cables

Comparison of conductive materials

Aluminum is one of the most common materials in the production of wires and cables. Its conductivity is approximately 62% that of copper, but due to the low density of aluminum, the conductivity per unit mass is twice that of copper.

However, compared to copper, aluminum has low mechanical strength and reduced contact properties. One of the negative properties of aluminum is rapid oxidation in contact with air and the formation of a refractory (with a melting point of about 2000 ° C) oxide film on its surface. Oxide film poorly conducts electricity and therefore prevents good contact.

In addition, aluminum-copper contact forms a "galvanic couple" in which the aluminum subjected to electrocorrosion is destroyed. This causes the connection to deteriorate. Used as electrical insulation rubber and plastic... In order to save scarce wires with copper wires, wires and cables with aluminum wires are mainly used for electrical wiring.

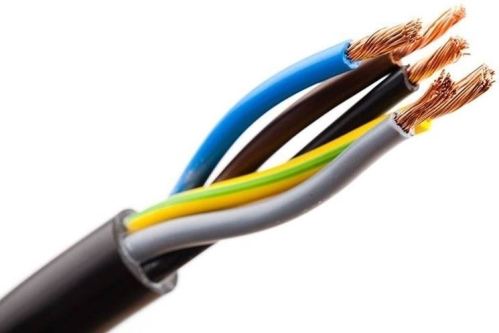

Differences in wiring products

The available assortment of wires, cables and cables is extremely diverse. They differ:

-

material of conducting wires (copper, aluminum, aluminum-copper);

-

cross section of wires (from 0.75 to 800 mm);

-

number of cores (single-core and multi-core, from 1 to 37 cores);

-

insulation (rubber, paper, yarn, plastic);

-

casings (rubber, plastic, metal),

-

covers etc.

Working and test voltage

Each wire, cable, cable has a working (nominal) and test voltage. These values for wires and cables characterize the dielectric strength of their insulation.

Operating voltage — this is the highest network voltage at which a wire, cable, cable can be used.

An example. With a working voltage of 380 V wire, it is suitable for networks of 380, 220, 127, 42, 12 V. But a cable whose working voltage is 220 V cannot be used in networks of 380 V and higher. In residential buildings, wires and cables are used for voltages of 660, 380 and 220 V. Inscriptions 660/660; 380/380 and 220/220 refer to stranded wires; they show the permissible voltage between adjacent wires.

Test voltage — determines the limit of dielectric strength of the applied insulation. He is much taller than the worker.

Effect of connected load

Installation wires must be suitable for the connected load. For the same brand and the same cross-section of the wire, loads of different magnitudes are allowed, which depend on the laying conditions and, therefore, on the possibility of cooling.

An example. Wires or cables placed in the open cool better than those placed in pipes or hidden under plaster.

The cross-section of the conductive wires is selected based on the maximum permissible heating of the wires, at which the insulation of the wires is not damaged. The permissible values of continuous load currents for wires, cables and cables are calculated and given in Installation Rules (PUE).

The allowable load (all other conditions being equal) with an increase in the section increases not proportionally to the section, but more slowly.

An example. With a cross section of 1 mm2, current 17 A. With a cross section of 1.5 mm2, not 25.5 A, but only 23 A.

When you put several wires in a common pipe, in a hidden cable channel, the words of their cooling deteriorate, they also heat up, so the permissible current for them must be reduced by 10 ... 20%.

Operating temperature of wires and cables in rubber insulation should not exceed + 65 ° C, in plastic — + 70 ° C. Therefore, at a room temperature of + 25 ° C, the permissible overheating should not exceed a temperature of +40 ... 45 ° C.

Insulation of wires and cables

Wires are manufactured with insulation for voltages of 380, 660 and 3000 V AC, cables for all voltages. Insulated wire has a conductive core enclosed in an insulating sheath made of rubber, polyvinyl chloride, or vinyl plastic.

To protect against mechanical damage and environmental influences, the insulation of some brands of wires is covered on the outside with a cotton braid impregnated with an anti-rot mixture. The insulation of wires intended for laying in places where there is an increased risk of damage due to mechanical stress is additionally protected by a braid of galvanized steel wire.

Calculation of the cross-section of the core

The cross-section of the wire is approximately determined by its diameter (S = 0.785d2), where d is the diameter of the core. Diameter can measure with a caliper.

If there is no caliper at hand, the diameter can be found as follows. 10 ... 20 turns of the wire stripped of insulation should be wound around a thick nail, screwdriver or other rod, tightly press the turns of the wire and measure the length of the spiral with a simple ruler. Dividing this length by the number of turns gives the desired core diameter.

On the day of determining the cross-section of multi-core wires and cables, measure the diameter of one vein, calculate its cross-section, then multiply the cross-section by the number of veins in the wire.

The exact cross-section of wires and cables with a voltage of up to 1000 V is determined based on two conditions.

First condition. According to the condition of heating with long-term rated current: Idop> Iр,

where Iadop is the long-term permissible current for the assumed cross-section of a wire or cable and the conditions for its laying. Data are given in PUE or reference literature; Ir — nominal current, A.

Second condition. According to the condition of compliance of the conductor cross-section with the protection class: Idop> Kz x In.pl.,

where Kz — protective factor; In.pl — rated fuse current, A.

Kz = 1.25 when protecting wires with rubber and plastic insulation in explosive and fire-hazardous, commercial, etc. premises with fuses and circuit breakers; when protecting the same wires in non-explosive and non-flammable rooms Kz = 1.0.

Lighting is additionally calculated for voltage loss.The permissible continuous current loads of wires and cables, as well as the selection of starting and protective equipment, wires and cables for separately mounted electric motors are found in the reference books.

Range of standard wire cross-sections

The range of standard wire cross-sections is large: from 0.03 to 1000 mm2. We will be interested in cross-sections from 0.35 (minimum cross-section for connecting household electrical appliances) to 16 mm2. The cross-sections of the wires are changed according to standard lines: 0.35; 0.5; 0.75; 1.0; 1.2 (copper only); 1.5; 2.0; 2.5; 3.0; 4.0; 5.0; 6.0; 8.0; 10.0; 16.0 mm2 — copper, aluminum and aluminum-copper wires.

Rules for Electrical Installation (PUE) installed minimum cross-sections of used building wires in mm2. They make up:

-

1 / 2.5 mm2 — for the line of group and distribution networks;

-

2.5 / 4.0 mm2 — for the line to residential shields with a measuring device;

-

4.0 / 6.0 mm2 — for the power grid and risers.

Here, in the numerator, the cross-sections of copper wires are indicated in mm2, in the denominator - aluminum and copper-aluminum.

According to the conditions of mechanical strength, the smallest sections S (or diameter d) wires were installed and PUE for branches from overhead lines to entrances to houses. They are equal: for copper wires, as well as for wires with a carrier cable of 4 mm2 in a range of up to 10 m or 6 mm2 in a range of up to 25 m. The diameter of steel and bimetallic wires must be 3 and 4 mm, respectively. The cross section of wires of aluminum and its alloys is 16 mm2.

At relatively low current values, the cross-section of the conductors is determined by the mechanical strength of the conductor, especially in the screw terminals.Based on this, the cross section of the copper wire should not be less than 1 mm2, aluminum — 2 mm2.

Advices. It is useful to check the cross-section of the wires to see if they agree with the maximum actual load and current of the fuses or circuit breaker. In this case, you should know that the load should not exceed 1 kW per 1.57 mm2 of the wire cross section.

Patch cables

Cord - two or more insulated flexible or highly flexible conductors with a cross-section of up to 1.5 mm2, twisted or laid in parallel, on which, depending on the operating conditions, a non-metallic sheath and protective coatings can be placed.

The cables are designed to connect electrical household appliances to the mains (eg table lamps, vacuum cleaners, electric shavers). Lived must be used multi-wire, in addition, the cores of the cable are connected to each other by twisting or a common braid.

Connecting cables for household appliances and lamps are very diverse. They can have two, three or four copper wires with a cross section of 0.35 to 4.0 mm2, normal or with increased flexibility.

Two-wire cables are used if the housing of the device (lighting body) does not require protective grounding (earthing). If grounding is required, use a three-wire cable. The cross-section depends on the amperage of the connected device (illuminant).

An example. Cross-sections of cables used with different groups of electrical appliances:

-

0.35 mm2 — used for cables for electric shavers;

-

0.5 mm2 — for table lamps, fans, televisions;

-

0.75 mm2 — for irons up to 500 W, refrigerators, vacuum cleaners.

The most common cables are:

-

heat resistant for irons and electric stoves;

-

in a waterproof cover;

-

in a gold and silver case for lamps with crystal elements.

Cables can be white, gray, brown, red, blue, light blue, black, yellow, ivory. The length of the cables is standardized:

-

2m — for refrigerators, irons and shavers;

-

3.5 m — for washing machines;

-

6m — for polishers and vacuum cleaners.

Cords can be cut at one or both ends and reinforced with non-detachable plugs and sockets for appliances.

How to choose the right wire or cable

The cross-section of the wires, depending on the load and the material (copper, aluminum), is selected according to the «Rules for electrical installation».

Consider the issue of replacing wires if there is no exact required version of wire, cable, cable.

Reading the rated voltage

It is necessary to pay attention to the nominal voltage of the wire proposed for replacement: it must not be less than the mains voltage.

Examples.

-

If the wires do not go outside the apartment, then the nominal voltage of the wire must be at least 220 V.

-

If the wires go outside the apartment, then the nominal voltage of the wire must be at least 380 V.

Material accounting

It is necessary to pay attention to the material of the core, considering that aluminum and aluminum-copper wires can always be replaced with copper. Copper wires cannot be replaced with aluminum and copper-aluminum in the following cases:

-

if flexibility is required (flexible wires must be copper);

-

if the wires are connected by soldering instead of screw terminals.

Measurement of the cross-section of the veins

You should pay attention to the cross-section of the veins. It should correspond to the load in amperes, i.e. be no less values specified in PUE… On the other hand, the cross-section should not be too large, otherwise the wire cannot be reliably connected to switches and contacts.

But the cross-section should not be too small, because the thin wire is difficult to pinch: it will hang. Therefore, the smallest cross-sections of the wire are set for connection to screw terminals: 1 mm2 for copper and 2 mm2 for aluminum wires. A washer with a cross section of 0.75 mm2 should be fitted. The cross-section of the wires for entering air into the building, according to the conditions of mechanical strength, should not be less than the above.

View additional terms

Solid wires can always be replaced with stranded (flexible) wires. In addition, attention should be paid to the conformity of the type of insulation with the installation conditions. So wires intended for laying in wet rooms can be laid in dry rooms, but under no circumstances should wires intended only for dry rooms be laid in wet rooms.

Heat-resistant wires, for example, a wire of the PRKA brand, intended for internal installation of electric stoves, cannot be replaced with «ordinary» wires: their insulation in the stove will simply burn.

The article uses materials from the book Koryakin-Chernyak S.L. Home Electrician's Handbook.