Insulators for poles and bushings

Station and hardware insulators distribution devices according to their purpose and design are divided into supporting and through. Support insulators are used to fasten busbars and busbars of open and closed switchgear and devices. Bushings they are used when passing current wires through walls or to introduce voltage into metal tanks of transformers, capacitors, switches and other devices.

Station and hardware insulators distribution devices according to their purpose and design are divided into supporting and through. Support insulators are used to fasten busbars and busbars of open and closed switchgear and devices. Bushings they are used when passing current wires through walls or to introduce voltage into metal tanks of transformers, capacitors, switches and other devices.

The main insulating material of post insulators is porcelain. Recently, polymer post and sleeve insulators have become popular. In bushings for voltages of 35 kV and above, in addition to porcelain, oil paper and oil barrier are widely used.

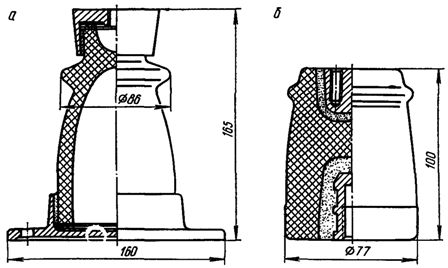

Insulators for internal poles for voltages of 3 - 35 kV are usually made of rod and consist of a porcelain body and metal fittings. In insulators with an internal sealed cavity (Fig. 1, a), the reinforcement in the form of a cap for fixing tires and a round or oval base is attached to porcelain using cement.

The rib is poorly developed and serves to somewhat increase the discharge voltage.The greatest influence is exerted by the edge located on the cap, which somewhat flattens the field in the region of the strongest sides, from where the discharge begins.

Rice. 1. Support insulators type OF-6 for indoor installation.

This edge is the largest. Insulators with internal fittings (Fig. 1, b) have lower weight, height and slightly better electrical characteristics compared to insulators with an air cavity. This is achieved because during the internal embedding of the reinforcement, the greatest stress is observed in the porcelain, there is no air cavity, and the reinforcement plays the role of an internal screen.

Support insulators for open switchgears have developed fins to provide the required discharge characteristics during rain.

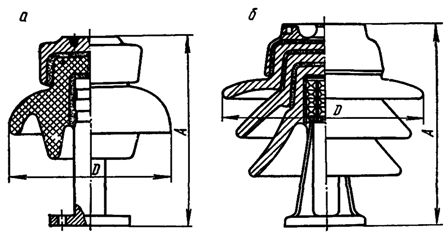

Supporting pin insulators of the ОНШ type are produced for voltages of 6 — 35 kV and consist of one (Fig. 2, a), two or three (Fig. 2, b) porcelain bodies, cemented to each other and with reinforcement. Busbars and insulators are fastened with bolts. For 110, 150 and 220 kV, pin insulators are assembled in columns of three > four and five ONSH-35 insulators, respectively.

Rice. 2. Support pins for external installation: a-ОНШ-10-500, b-ОШП-35-2000.

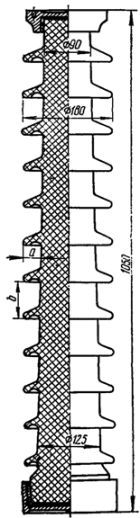

Rod insulators for external mounting, type ONS are issued for voltages up to 110 kV (Fig. 3). The number and size of ribs are selected based on experience. When the ratio of edge overhang a to edge spacing is about 0.5, the wet discharge voltages for a given discharge spacing are the highest.

Rice. 3. ONS-110-300 External Mount Support Rod Insulator.

Hollow support rod insulators are also used. The diameter of such insulators is larger than that of solid rod insulators, which guarantees their greater mechanical strength.However, internal cavity discharges are possible with such insulators to prevent the internal cavities from being sealed with porcelain baffles or filled with compound.

For voltages of 330 kV and more, single columns of insulators are very high and do not provide the necessary mechanical bending strength. Therefore, at these voltages, support structures in the form of a conical tripod of three columns of insulators are most often used. Under bending forces, insulators in such structures work not only in bending but also in compression.

The stresses in the elements of the tall column of supporting insulators, as well as in the hanging garland, are unevenly distributed. To equalize the voltage, toroidal screens fixed on the upper element of the column are used.

Rice. 4. Support rod insulators OS

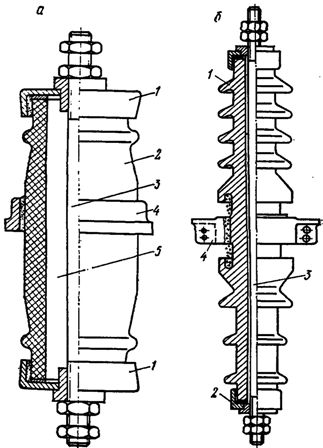

Bushings for 6 — 35 kV are most often made of porcelain. Their structural performance is determined by voltage, current, permissible mechanical bending load and the environment.

The insulator (Fig. 5) consists of a cylindrical porcelain body 1 firmly fixed by means of cement-reinforced metal end caps 2 with a conductive rod 3. A flange 4 is used to fasten the insulator to the wall of the building or the body of the apparatus. Like other types of insulators, bushings are made in such a way that the breakdown voltage is higher than the overlap voltage across the surface.

The breakdown voltage of porcelain bushings depends on the thickness of the porcelain. However, the design of such insulators is practically determined by the required mechanical strength, the overlap stress of the structure and measures to eliminate corona.

Insulators for 3-10 kV are made with an internal air cavity 5.

Rice. 5. Porcelain bushings: a — for voltages 6-10 kV for internal installation, b — for voltage 35 kV of solid construction for external installation.

No special measures need to be taken to eliminate the possibility of corona formation at such voltages. At voltages of 20–35 kV, corona may appear on the rod opposite the flange, where the highest field strength is observed in air. To prevent the formation of a corona, insulators for such voltages are produced without an air cavity (Fig. 5, b). In this case, the outer surface of the porcelain is metallized and bonded to the rod.

To eliminate the possibility of dropping the flange, the porcelain surface below it is also metallized and grounded. The slip stresses from the flange on the porcelain surface and therefore the surface overlap stresses can be increased by reducing the surface capacitance. For this, either the diameter of the flange insulator is increased or the surface of the insulator is ribbed, with more massive ribs near the flange.

Rice. 6. Polymer sleeve 10 kV

Insulators designed to inject voltage from one medium to another (air — oil, etc.) are asymmetrical with respect to the flange. For example, the overlap path in oil can be traveled 2.5 times less than in air. The bushing, one end of which is indoors and the other outdoors, has also been made asymmetrical, with the outer part having more developed ribs to increase wet discharge stress.