Starting a wound rotor motor

The starting properties of the asynchronous motor depend on the characteristics of its design, in particular on the rotor device.

The starting of an induction motor is accompanied by a transient process of the machine, associated with the transition of the rotor from a state of rest to a state of uniform rotation, in which the torque of the motor balances the moment of the resistance forces on the shaft of the machine.

When starting an asynchronous motor, there is an increased consumption of electrical energy from the supply network, which is spent not only to overcome the braking torque applied to the shaft and cover the losses in the asynchronous motor itself, but also to communicate a certain kinetic energy to the moving links of the production unit. Therefore, when starting, the induction motor must develop increased torque.

For an induction motor with a rotor, the starting torque corresponding to slip with n = 1 depends on the active resistances of the adjustable resistors introduced in the rotor circuit.

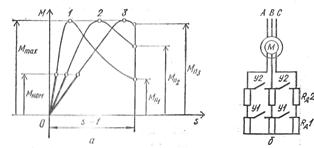

Rice. 1.Starting a three-phase asynchronous motor with a wound rotor: a — graphs of the torque dependence of a motor with a wound rotor from slippage at various active resistances of resistors in the rotor circuit, b — a circuit for connecting resistors and closing contacts for acceleration to the rotor circuit.

So, with closed accelerating contacts U1, U2, i.e. when starting an induction motor with a short circuit of slip rings, the initial starting torque Mn1 = (0.5 -1.0) Mnom and the initial starting current Azn = ( 4.5 — 7) Aznom and others.

A small starting torque of an asynchronous electric motor with a wound rotor may be insufficient to drive a production unit and its subsequent acceleration, and a significant starting current will lead to increased heating of the motor windings, which limits its switching frequency, and in networks with low power leads to a temporary voltage drop undesirable for the operation of other receivers. These circumstances may be the reason that precludes the use of wound-rotor induction motors with large starting current to drive working mechanisms.

The introduction of adjustable resistors in the rotor circuit of the motor, called starting resistors, not only reduces the initial starting current, but at the same time increases the initial starting torque, which can reach the maximum torque Mmax (orig. 1, a, curve 3), if the critical slip of the phase-wound rotor motor

skr = (R2' + Rd') / (X1 + X2′) = 1,

where Rd' — active resistance of the resistor in the phase of the motor rotor winding, reduced to the phase of the stator winding.Further increasing the active resistance of the starting resistor is impractical, as it leads to a weakening of the initial starting torque and exiting the point of maximum torque in the slip region s> 1, which excludes the possibility of accelerating the rotor.

The required active resistance of the resistors to start a phase rotor motor is determined based on the starting requirements, which can be light when Mn = (0.1 — 0.4) Mnom, normal if Mn — (0.5 — 0.75) Mn, and severe at Mn ≥ I.

In order to maintain a sufficiently large torque with a phase-wound rotor motor during the acceleration of a production unit, in order to reduce the duration of the transient process and reduce the heating of the motor, it is necessary to gradually reduce the active resistance of the starting resistors. Permissible change of torque during acceleration M (t) determined by electrical and mechanical conditions limiting the peak torque limit M> 0.85Mmax, the switching moment M2 >> Ms (Fig. 2), as well as acceleration.

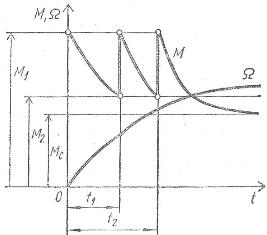

Rice. 2. Starting characteristics of a three-phase asynchronous motor with a wound rotor

The inclusion of the starting resistors is ensured by successive inclusion of the accelerators Y1, Y2, respectively, at times t1, t2, counted from the moment of starting the engine, when during acceleration the torque M becomes equal to the switching moment M2. Therefore, during the entire start-up, all peak torques are the same and all switching torques are equal to each other.

Since the torque and current of the asynchronous motor with a wound rotor are mutually related, it is possible to set the peak current limit during rotor acceleration I1 = (1.5 — 2.5) Aznom and switching current Az2, which should to ensure the switching moment M2 > M.° C.

Disconnection of asynchronous motors with a wound rotor from the supply network is always carried out with a short circuit of the rotor circuit in order to avoid the appearance of overvoltages in the phases of the stator winding, which can exceed the nominal voltage of these phases by 3 — 4 times, if the rotor circuit is open at the moment the motor stops.

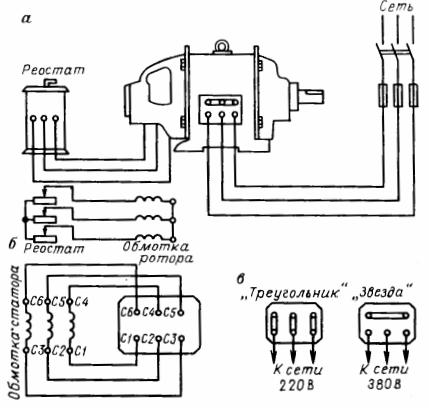

Rice. 3. Connection scheme of the motor windings with a phase rotor: a — to the power network, b — rotor, c — on the terminal board.

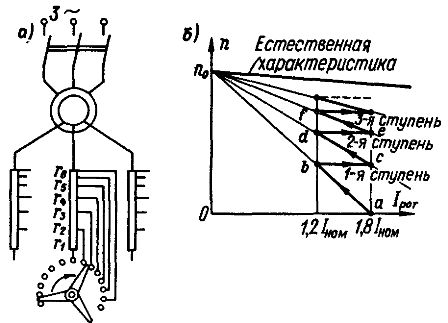

Rice. 4. Starting the motor with a phase rotor: a — switching circuit, b — mechanical characteristics