Thermal insulation research

Reducing energy costs is one of the main goals of energy conservation in the construction industry. It is possible to solve this problem simply and effectively by conducting a thermal insulation inspection of buildings and electrical equipment... Such a study allows you to identify heat leakage in various residential and industrial premises.

Reducing energy costs is one of the main goals of energy conservation in the construction industry. It is possible to solve this problem simply and effectively by conducting a thermal insulation inspection of buildings and electrical equipment... Such a study allows you to identify heat leakage in various residential and industrial premises.

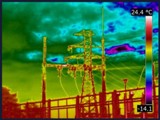

The thermal imager helps to quickly and efficiently find possible malfunctions in the building envelope, analysis of the operation of the air conditioning system, electrical equipment and pipelines.

Objects with temperatures above absolute zero emit infrared waves. The thermal video image obtained in the infrared wavelength range (invisible to the eye) allows to obtain a complete picture of the temperature distribution over the area of the object without the absence of contact with the object. With the help of a heat insulator, you can also identify temperature deviations that carry information about the processes inside the object and about its structure.Diagnostics by the method of thermal control can be carried out during the operation of the facility. That is, to carry out an inspection, it is not necessary to turn off electrical equipment, stop production, etc.

A thermal insulation survey identifies areas of defects in the building envelope that lead to heat loss. The exact location of these defects is recorded on the thermogram.

With the help of a heat insulator, it is possible to identify such defects as design flaws: poor-quality installation of window frames, cold areas, defects in the thermal insulation of joints between panels; the actual amount of heat loss and compare it with the allowable amount of heat loss; a flaw in the design of the heating system; places of possible fogging of the walls, leaks in the roof; places to install electric heaters in heated floors, places to lay pipes.

The periodically conducted thermal insulation inspection of the electrical equipment ensures continuous power supply to residential, administrative, and industrial premises. It also extends the service life of the equipment. Thermal inspection of electrical equipment quickly and safely detects faults at an early stage. This allows you to prevent an accident in time.