Manometric thermometers

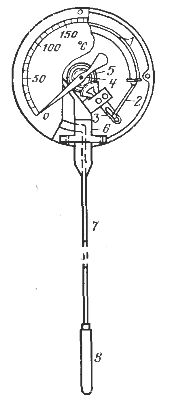

A manometric thermometer (Fig. 1) consists of a thermometer 8, a tubular (or spiral) spring 1 and a connecting capillary 7 filled with gas, liquid or steam. When the temperature of the space in which the bulb is located, the pressure in the system changes and therefore in the spring. The latter has an oval or elliptical cross-section (Bourdon spring) and therefore, when the pressure in it changes, it unwinds or twists, and since one end of it is firmly fixed in the holder 6, this leads to the movement of its other end, the movement through the strap 2, sector 3 and the earpiece 5 is transferred to the directional arrow 4.

A manometric thermometer (Fig. 1) consists of a thermometer 8, a tubular (or spiral) spring 1 and a connecting capillary 7 filled with gas, liquid or steam. When the temperature of the space in which the bulb is located, the pressure in the system changes and therefore in the spring. The latter has an oval or elliptical cross-section (Bourdon spring) and therefore, when the pressure in it changes, it unwinds or twists, and since one end of it is firmly fixed in the holder 6, this leads to the movement of its other end, the movement through the strap 2, sector 3 and the earpiece 5 is transferred to the directional arrow 4.

Manometric thermometers allow you to measure temperatures from –130 to + 550 ° C.

Rice. 1. Bourdon tube spring manometric thermometer.

The advantages of manometric thermometers include the ability to transmit readings over relatively long distances, since the capillary can be made up to 30-60 m long, as well as the large power of the measuring system, to which writing and contact devices can be attached.Therefore, these devices can be manufactured as indicating, recording, signaling and regulating devices.

The disadvantages of manometric thermometers include the large size and thermal inertia of the sensor (bulb), the gradual deformation in the operation of the bulb and capillary, the collapse of the calibration, as a result of which their periodic inspection is required, and the relative difficulty of repair.

The most common gas manometric thermometers of the TG type are filled with nitrogen and have a measurement range of 0 to 300 °C.

Rice. 2. Manometer thermometer

Gas thermometers are filled with nitrogen under pressure, so the influence of atmospheric pressure on the readings of the device is minimized and can be neglected. Naturally, the ambient temperature affects their readings, but with the correct choice of the ratio of the volumes of the balloon and the capillary tube, they can work quite accurately with a capillary length of up to 30 - 40 m. Methyl alcohol, xylene or mercury can be used as working fluid.

Steam manometric thermometers have a thermometer filled 2/3 of the volume with a low-boiling liquid, such as benzene, acetone, methyl chloride. The remaining third of the cylinder is occupied by the vapors of these liquids. The capillary and spring are filled with a liquid that does not evaporate at operating temperatures (for example, a mixture of glycerin, water and alcohol).

Since the elasticity of saturated vapor increases very rapidly with temperature, the effect of liquid expansion in the capillary and spring is negligible, making it possible to manufacture devices with relatively smaller thermocouples.The disadvantage of manometric thermometers with steam is the insufficient upper limit of the measured temperatures of 100 — 200 ° C.

It is most convenient to use manometric thermometers for measuring and regulating the temperature of liquids, for example for indicating and signaling the temperature of oil in transformers, including furnaces. In electric furnaces, thermoballs are practically not used because of the large thermal inertia and the size of the thermoball.