Welding power source parameters

Sources of welding current must ensure stable burning of the arc, stability of welding modes and safe maintenance of installations. These requirements are met by correct selection of power supply parameters: no-load voltage, external characteristics, welding current adjustment method.

Sources of welding current must ensure stable burning of the arc, stability of welding modes and safe maintenance of installations. These requirements are met by correct selection of power supply parameters: no-load voltage, external characteristics, welding current adjustment method.

Open circuit voltages are selected based on reliable arcing and safety in service. Increasing the voltage makes it easier to strike the arc, but at the same time increases the danger of injury to the welder. In addition, an increase in the open circuit voltage of AC power supplies (welding transformers) leads to an increase in the magnetizing current and a decrease in cosφ.

Arc ignition voltage alternating current is 50 — 55 V, therefore the open circuit voltage cannot be lower than this value. The upper limit of Uо values is limited by safety conditions and is 60 — 75 V, and for 2000 A welding transformers it should not exceed 90 V.DC arcing occurs at a lower voltage, around 30 — 40 V. Open circuit voltage of DC supplies current is in the range 45 — 90 V.

External characteristic of an electrical product (device) — the dependence of the voltage at the terminals of an electrical product (device) on the current flowing through the load connected to these terminals. (GOST 18311-80).

An external characteristic of welding power sources is the dependence of the voltage at its output terminals Un on amperage load

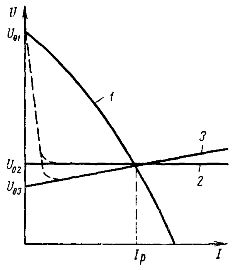

By the nature of this dependence, the external characteristic can be (Fig. 1):

1) fall,

2) difficult,

3) increase.

Rice. 1. Types of external characteristics of arc power sources: 1 — falling, 2 — solid, 3 — increasing.

The arc and the power source form a system that will be in stable equilibrium if the random changes in current strength decrease with time, that is, the system will return to its initial state.

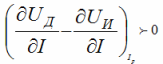

The condition for stability in static mode is reduced to the fact that the difference between the derivatives of the voltage with respect to the current of the static characteristics of the arc and the power source at the operating point is positive

The condition is met if with a falling arc characteristic the external characteristic of the power source will be more falling and with a rising arc characteristic the external characteristic of the source will be less rising.

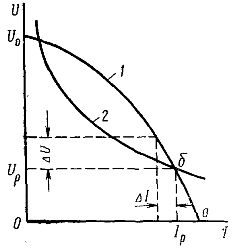

Figure 2 shows the combined drop characteristics of power source 1 and arc 2. The moment the electrode touches the workpiece, the short-circuit current flows through the welding circuit corresponding to point a.When the electrode is withdrawn, an arc occurs, the voltage increases along the curve 1 to point b, corresponding to stable burning of the arc.

Rice. 2. Combined external power source characteristic (1) and arc current-voltage characteristic (2).

The falling external characteristic is used in manual welding machines, where it is necessary to guarantee the stability of the arc and a small change in the welding current when changing the length of the arc. The change in voltage due to a change in the length of the arc by a certain amount ΔU (Fig. 2) leads to a slight change in the welding current by ΔAz.

The falling external characteristic provides a small multiple of the short-circuit current, which should not exceed 1.4. At high short-circuit currents, the power source experiences large overloads, and the welding quality and service safety deteriorate due to metal spatter.

Sources with solid and increasing characteristics are used for submerged arc welding and in shielding gases (argon, carbon dioxide).

In most cases, the falling external characteristic of the power supply is more appropriate. In welding power sources, it is created by a voltage drop in the source itself or in a separate resistance included in the welding circuit.

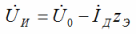

In the general case, the external characteristic equation is nonlinear and has the form

where Uo — open-circuit voltage of the power source, zd — total equivalent resistance of the power source together with additional resistance, Azd — arc current.

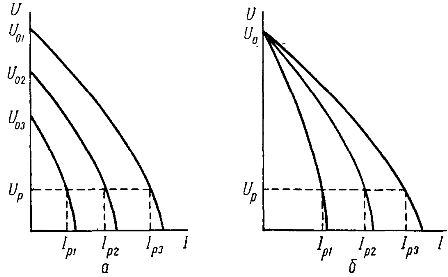

Regulation of the welding current necessary when welding parts of different thickness.For this purpose, the power sources are equipped with devices for stepwise or smooth adjustment of the welding current, which provide the possibility of operation at different characteristics (Fig. 3).

Rice. 3. External characteristics of arc energy sources when adjusting the welding current: a — by changing the open circuit voltage Uo, b — change in the equivalent resistance ze.

Mode of operation of welding power sourceswork in periodic mode is characterized by the relative duration of PR, which is the part of the time of continuous operation under load from the duration of the entire work cycle.

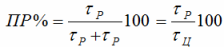

PR is usually expressed as a percentage

where τp — time of continuous operation under load, τn — time of pause, τc is the time of the work cycle.

If the power source is disconnected from the network during the break, they do not talk about the duration of the PR, but the duration of the activation of the PV, which is determined in the same way as the duration of operation (PR).

The relative duration of the PR is the passport parameter of the power source, which must be taken into account when choosing a source and its operation. Exceeding the PR relative to the passport leads to overheating and damage to the welding equipment.

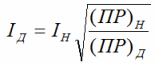

When the source operates in rated mode, the allowable current is determined by the ratio

where the index «n» refers to the nominal parameters and «d» to the actual mode parameters. In continuous mode PR = 100%.