Electric arc welding

In the electric arc welding method, an arc discharge is generated and maintained between the metal rod of the electrode and the workpiece. The thermal energy of the arc locally melts the workpiece and the metal core of the electrode to form a weld pool and protective slag.

In the electric arc welding method, an arc discharge is generated and maintained between the metal rod of the electrode and the workpiece. The thermal energy of the arc locally melts the workpiece and the metal core of the electrode to form a weld pool and protective slag.

The welding power source for electric arc welding provides direct or alternating current with an intensity of 30 to 400 amperes, depending on various parameters such as electrode diameter, electrode coating properties, welding position, type of connection, dimensions and characteristics of the workpieces. The voltage of the welding energy source must be greater than the ignition voltage (see Welding power source parameters).

The coated electrode is clamped into an electrode holder connected to one of the electrical output terminals of the welding station. "Ground" is connected to the source of welding current and is located on the workpiece.

The ignition of the arc is achieved by rubbing the tip of the electrode on the workpiece or by bringing the electrode a few millimeters closer to the surface of the workpiece.The arc must be maintained at all times, keeping the distance between the tip of the electrode and the workpiece constant to avoid shorting.

Electric arc welding

The welding electrode consists of two parts:

1. The metal core is cylindrical in the form of a rod in the center of the electrode. The main role of the rod is to conduct electric current and form the weld metal.

2. Cover: outer cylindrical part of the electrode. It helps protect the weld pool from oxidation by atmospheric air by creating a gas atmosphere around the molten metal. The coating also forms a protective slag at the top of the weld. This slag protects the melt from oxidation and rapid cooling. The coating plays an important role in the stability and ionization of the arc. The coating has a complex chemical composition and may include metallic, mineral and organic components.

The diameter of the coated electrode varies from Ø 1.6 to Ø 8 mm. Total length from 250 to 500 mm. Some electrodes can have a diameter of 10 … 12 mm and a length of 1000 mm for special types of work.

The main types of coatings for welding electrodes for electric arc welding:

1) Acidic (iron oxide and iron-containing alloys).

1) Acidic (iron oxide and iron-containing alloys).

2) Basic (based on calcium carbonate and calcium fluoride).

3) Cellulose (based on cellulose).

4) Rutile (based on titanium oxide).

5) Contains iron powder (based on metal powder).

6) Special (combinations of the above types with the addition of various components).

Types of work in which electrodes with different coatings are used:

1) Rutile — for current welding operations.

2) Main — for constructions working under pressure or with increased strength requirements.

3) Cellulose — for deep penetration of root sutures in a horizontal position.

Storage and preparation of electrodes before arc welding:

The rutile and base electrodes should be baked in an oven at 300 degrees Celsius for 2 hours. When dry, such electrodes should be processed at 120 degrees Celsius in portable ovens in the welding area. Other electrodes (rutile, cellulose and acid) are stored in a heated room and relative humidity below 60%.

The new manufacturing technology and vacuum packaging of the main electrodes provide a very low moisture coating that does not require annealing and drying before use.

Welding electrodes

Modes of arc welding with covered electrodes:

If the strength of the welding current is low, the penetration of the weld is low, the electric arc is unstable, and the weld metal has pores and slag inclusions, which deteriorate the properties of the weld. At high current, the molten metal becomes too liquid.

The choice of amperage depends on: the diameter of the electrode, the chemical properties of the electrode, the characteristics of the workpiece, the welding position, the thickness of the workpiece.

The intensity of the welding current decreases with increasing arc length. Conversely, as the arc length decreases, the current increases.

Dependence of the welding current on the diameter of the electrode

Welding current depending on the thickness of the part

Root stitches are usually made with negative polarity: the plug of the electrode holder is connected to the (-) terminal, the plug of the ground clamp is connected to (+) of the current source.

Finishing welding passes and filling with molten metal are usually carried out with positive polarity: the plug of the electrode holder is connected to the (+), the plug of the ground clamp is connected to the (-) terminal.

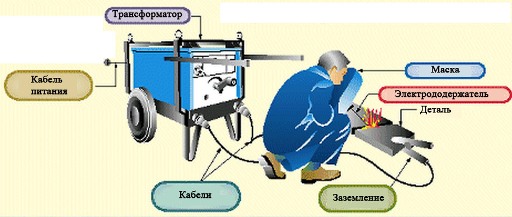

A typical composition of a welder's workplace includes:

1. Welding current source.

2. Electrode cable with holder.

3. Ground clamp with wire.

4. Portable basic electrode oven.

5. Special welding mask with tinted glasses, welding gloves and clothing.

6. Wrecking hammer and wire brush for cleaning welds.

7. Electric angle grinder for cleaning edges and seams.

8. Protective screens or curtains.

9. Ventilation system.

The workplace of the welder