Surface coatings

Layering technology is one of the methods of surface hardening of parts. The surface of the coatings is made by fusing the filler material (powder, wire, electrode) with the base material. According to the type of coating applied, the following main types of layering can be distinguished:

Layering technology is one of the methods of surface hardening of parts. The surface of the coatings is made by fusing the filler material (powder, wire, electrode) with the base material. According to the type of coating applied, the following main types of layering can be distinguished:

1. Wear-resistant surfaces (perlite-sorbitol, boron, martensitic, chromium, high-manganese, austenitic steel, tungsten carbide, stellite).

2. Corrosion-resistant coating (ferritic, austenitic, corrosion-resistant steel «Monel», «Inconel», «Hastelloy» and others, nickel, nickel alloys, copper and its alloys).

3. Heat-resistant flooring.

4. Heat-resistant flooring.

Indoor flooring

Covering can be done in several ways. The most widely used in the industry are the following:

1) Gas lining.

2) Arc cladding with coated electrodes.

3) Submerged arc welding (wire, strip).

Strip electrode cladding under a layer of flux

4) Open arc surface with core wire.

5) Lining in a carbon dioxide environment.

6) Lining in an inert gas environment (consumable or tungsten electrode).

7) Electroslag surface.

Scheme of deposition of electroslag: 1 — electrode feed rollers, 2 — electrode, 3 — mouthpiece, 4 — flux hopper, 5 — flux, 6 — liquid slag, 7 — liquid metal bath, 8 — base metal, 9 — weld metal, 10 — power source, 11 — solid slag crust, 12 — layering direction

8) Plasma surface.

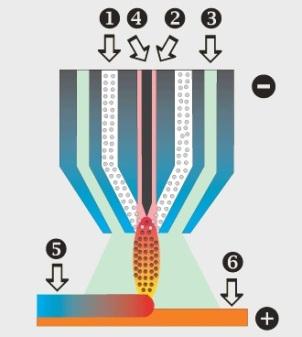

Scheme of plasma cladding: 1 — carrier gas, 2 — gas forming the plasma, 3 — protective gas, 4 — electrode, 5 — applied layer, 6 — base metal

9) Laser cladding.

10) Single and multi-electrode surfacing.

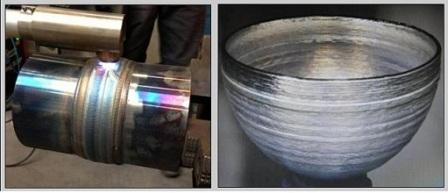

Examples of applying surfaces

Surface technology has the following advantages compared to other methods (spraying, carburizing, nitriding, electrolytic deposition, etc.):

1. High productivity (layering with strip electrodes allows to achieve a layering speed of up to 25 kg / h).

2. Possibility of applying thick coatings. This property makes it possible to successfully use flooring for repairing parts. At the same time, there are no restrictions on the size of the welded products.

3. Simplicity of technology. Mechanized arc surfacing can be performed by moderately skilled welders.

4. The economic efficiency of the technology makes it possible to produce parts with base metal from carbon structural steels with a surface surface of a metal with specific properties and a high price.

5. The properties of the base material do not play a large role in the hardness of the wear-resistant coating. For other methods, such as hardening, nitriding, the properties of the base metal are decisive. If the base metal of the seam has low weldability, then a layer of low-carbon steel is applied beforehand.For titanium coatings, the layering method is inapplicable due to the formation of brittle intermetallic joints.

Disadvantages of the surface include the following:

1) The high-temperature interaction of the base and the applied metal can provoke their mutual diffusion and, as a result, deterioration of the properties of the applied coating.

2) Possibility of product deformations.

3) Manual welding requires high qualification of the welder.

4) Uneven physico-mechanical characteristics of the welded parts. The welding properties are inherent to the applied layer.

5) Difficulty in applying complex shaped products.

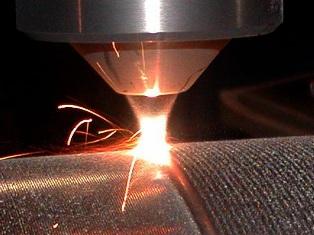

Installation of plasma cladding

Surface application practice includes the following works:

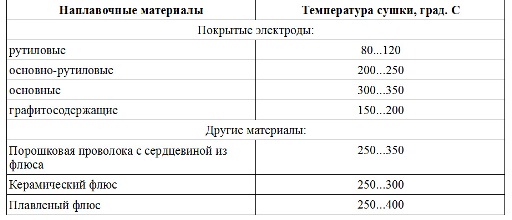

1. Calcination of surface materials (table 1). This measure makes it possible to reduce the amount of diffusible hydrogen in the overlay layer.

2. Surface cleaning from rust and dust, degreasing, drying, surface preparation (if necessary).

Preparation of the surface for layering: 1 — correct groove, 2 — irregular channel

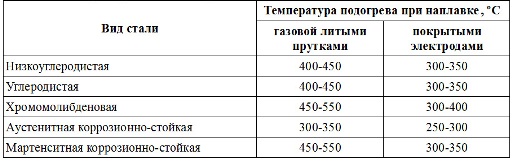

3. Preliminary heat treatment, including normalization (annealing) to obtain a stable structure and actual heating (table 2).

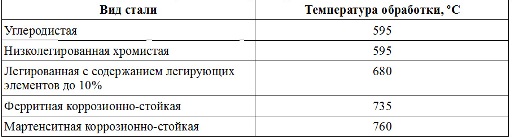

4. Subsequent heat treatment (tempering or annealing) to relieve stress and/or forge the applied layer. This treatment is especially necessary for welded types of flooring (table 3).

5. Processing to achieve finishing dimensions. Hard alloy surfaces are heat treated to reduce hardness before machining. Machining is done with a carbide cutting tool.

6.Paving quality control is carried out by external inspection (detection of undercuts, sagging, surface cracks), by detection of capillary defects with fluorescent or color penetrant, ultrasonic or X-ray defectoscopy. The hardness of the applied layer is also determined.

Table 1. Annealing of surface materials

Table 2. Preheating of steel before lamination

Table 3. Subsequent heat treatment

The most common layering methods are arc and gas. When gas coatings cover large parts, they are heated from the opposite side. The surface is carried out with a carburizing flame at a distance of about 3 mm from the surface. The flame must be wider and shorter than in gas welding.

Installation for automatic arc surfacing

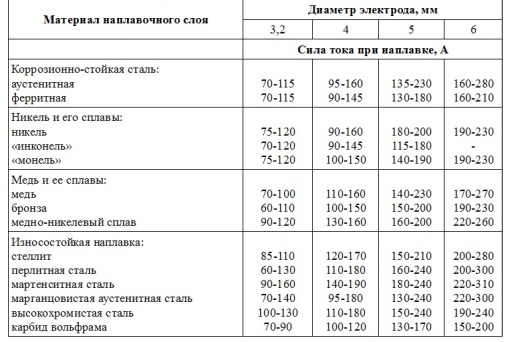

The modes of applying an electric arc are given in table. 4.

Table 4. Arc application modes

Covering of carbon dioxide is done using wire; when operating with direct current, an increase in wire protrusion should be accompanied by an increase in feed rate. The overhang is usually 20 mm.

Submerged arc surfacing is used for high-performance surfacing of turning bodies. The thickness of the applied layer is usually 1.5 ... 20 mm.

Installation for layering of wheels under a layer of flow

Welding equipment can be of two types — universal, based on universal metal-cutting machines, and specialized, for processing specific types of parts.

See also: Spraying methods