Automation of power supply management systems

Automated control system or ACS — a complex of hardware and software designed to control various processes within a technological process, production, enterprise. ACS are used in various industries, energy, transportation, etc.

Automated control system or ACS — a complex of hardware and software designed to control various processes within a technological process, production, enterprise. ACS are used in various industries, energy, transportation, etc.

In order to increase operational reliability, durability and efficiency of energy equipment, to solve the problems of dispatching, production-technological and organizational-economic management of the energy sector, enterprises can be equipped with automated energy management systems (ASUE).

These systems are subsystems of automated enterprise management systems (ACS) and must have the necessary means to transmit information from the control rooms to the power supply system in an amount agreed with the latter.

The sets of tasks of the automated control system in each energy sector must be selected based on production and economic feasibility, taking into account the rational use of available standard solutions and the capabilities of the exploited technical means.

Automated electrical equipment management system (ACS SES) is an integral part of the automated management system and, as a rule, includes a dispatch system for power supply and repair of electrical installations, distribution and sale of electricity, as well as a system for managing production and economic processes in the electrical industry.

For control and reporting of energy resources (electricity, heat, water) in ASUE, a special subsystem ASKUE (automated system for monitoring and reporting of energy resources) is included... The heat and water supply subsystem of the enterprise in ASUE should be highlighted separately.

The automated electrical equipment management system provides the following functions:

-

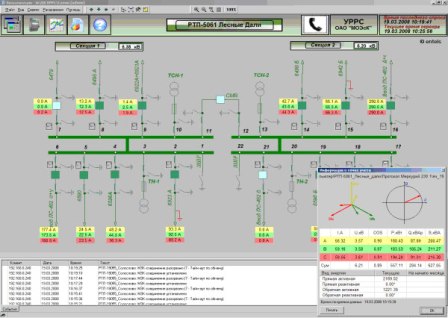

display the current state of the main power circuit in the form of a mnemonic diagram;

-

measurement, control, display and logging of parameters;

-

processing and displaying information about the state of the main circuit and equipment in text (table) and graphic form;

-

remote control of the switching of the switches of the main circuit with control of the actions of the operator;

-

processing stationary data for various operational purposes;

-

diagnostics of protection and automation with alarm;

-

remote change of digital relay protection and automation settings, control of their commissioning;

-

registering and signaling the occurrence of ferroresonance modes in the network;

-

validation of input information;

-

equipment diagnostics and control;

-

formation of a database, storage and documentation of information (maintenance of daily list, list of events, archives);

-

technical (commercial) electricity metering and control of energy consumption;

-

control of power quality parameters;

-

automatic emergency control;

-

registration (oscillography) of parameters of emergency and transient processes and analysis of oscillograms;

-

control of the battery mode and isolation of its circuits;

-

diagnostics of the condition of the ACS SES equipment and software;

-

transmission of information about the state of the power supply system to the technological ACS through its communication channel to the Central Control Center and to other enterprise services.

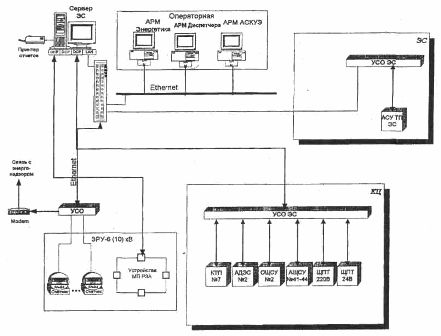

Fig. 1 shows an example structural diagram of the ACS of an SES compressor station. The structure of the ACS of the SPP depends on the type of compressor station (electric or gas turbine), the presence of an auxiliary power plant (ESP) of the compressor station and the modes of its operation. The degree of integration of the ESN into the power supply system (SES) is also important.

Rice. 1. Block diagram of ACS SES KS

The ESS objects included in the SES ACS are listed below:

-

external switchgear 110 kV (external switchgear 110 kV);

-

complete switchgear 6-10 kV (switchgear 6-10 kV);

-

power plant for own needs;

-

complete transformer substation (KTP) for auxiliary needs (SN);

-

KTP of the production and operation unit (KTP PEBa);

-

KTP of gas air cooling units (KTP AVO gas);

-

KTP of auxiliary structures;

-

KTP of water intake facilities;

-

automatic diesel power plant (ADES);

-

general station control station board (OSHCHSU);

-

DC board (SHTP);

-

air conditioning and ventilation systems, etc.

The main differences between SPP's ACP and technological ACS are:

-

high speed at all levels of the management process, adequate speed of the processes taking place in the electrical networks;

-

high immunity to electromagnetic influences;

-

the structure of the software.

Therefore, as a rule, during the design process, the ACS of the SES is separated into a separate subsystem, connected to the rest of the ACS through the bridge. Although the principles and capabilities for building deeply integrated systems currently exist.

The operating mode of the technological equipment determines the operating mode of the power equipment. Therefore, the ASUE subsystem as a whole is entirely dependent on technological processes. The ASUE subsystem, as well as the APCS, actually define the ability to build production information management systems.

The automated commercial electricity metering system provides the known benefits of metering arrangements using automated systems for monitoring, measuring and managing electricity consumption. Such systems have been used for many years both abroad and in Russia in medium and large industrial enterprises. In addition to accounting functions, they also typically monitor and manage energy consumption in these businesses.

The main economic effect for consumers of using these systems is to reduce payments for energy and capacity used, and for energy companies to reduce peak consumption and reduce capital investment to increase peak generation capacity.

The main objectives of AMR are:

-

application of modern methods for reporting electricity consumption;

-

cost savings due to reduced payments for consumed electricity;

-

optimization of power and electricity distribution modes;

-

transition to multi-tariff electricity metering; — operational control of full, active, reactive power, etc.;

-

power quality control. ASKUE offers a solution to the following tasks:

-

on-site data collection for use in custodial transfers;

-

collection of information at the highest level of management and formation of this data basis for trade settlements between market entities (including complex tariffs);

-

formation of the balance of consumption by subdivisions and the enterprise as a whole and by AO-energy zones;

-

operational control and analysis of electricity regimes and energy consumption by the main consumers;

-

control of the reliability of the readings of electricity and measuring devices;

-

formation of statistical reporting;

-

optimal control of user load;

-

financial and banking transactions and settlements between users and sellers.

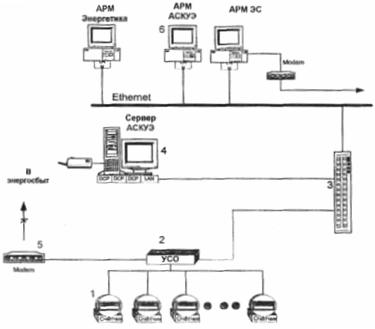

The block diagram of ASKUE is shown in Fig. 2.

Rice.2. Structure diagram of ASKUE: 1 — electricity meter, 2 — controller for collection, processing and transmission of electric energy readings, 3 — concentrator, 4 — ASKUE central server, 5 — modem for communication with power supply, 6 — automated place (AWS ) ASK

Process control systems for power plants is an integrated automated system consisting of two main subsystems: the automatic control system of the electrical part and the automatic control system of the thermomechanical part, which have completely different requirements.

The main tasks of the integrated APCS of the power plant are to ensure:

-

stable operation of the power plant in normal, emergency and post-emergency mode;

-

management effectiveness;

-

the ability to include the automated power plant process control system in the higher-level dispatch control system.

ACS for heat supply or ACS for heat energy is an integrated, multi-component, organizational and technological automated system for managing the heat sector.

ACS of the heat supply allows:

-

improving the quality of heat supply;

-

optimizes the operation of the heat economy by applying the specified technological regimes;

-

reduction of heat losses due to early detection of emergency situations, localization and elimination of accidents;

-

provide communication with the highest levels of management, which significantly improves the quality of management decisions made at these levels.

Read also: ACS TP of substations, automation of transformer substations